Protruding rotating scaffold

A scaffolding and coat technology, which is applied in the direction of scaffolding supported by housing structure, housing structure support, housing structure support, etc., can solve the problems of inconvenient construction and sloppy handling of work details.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

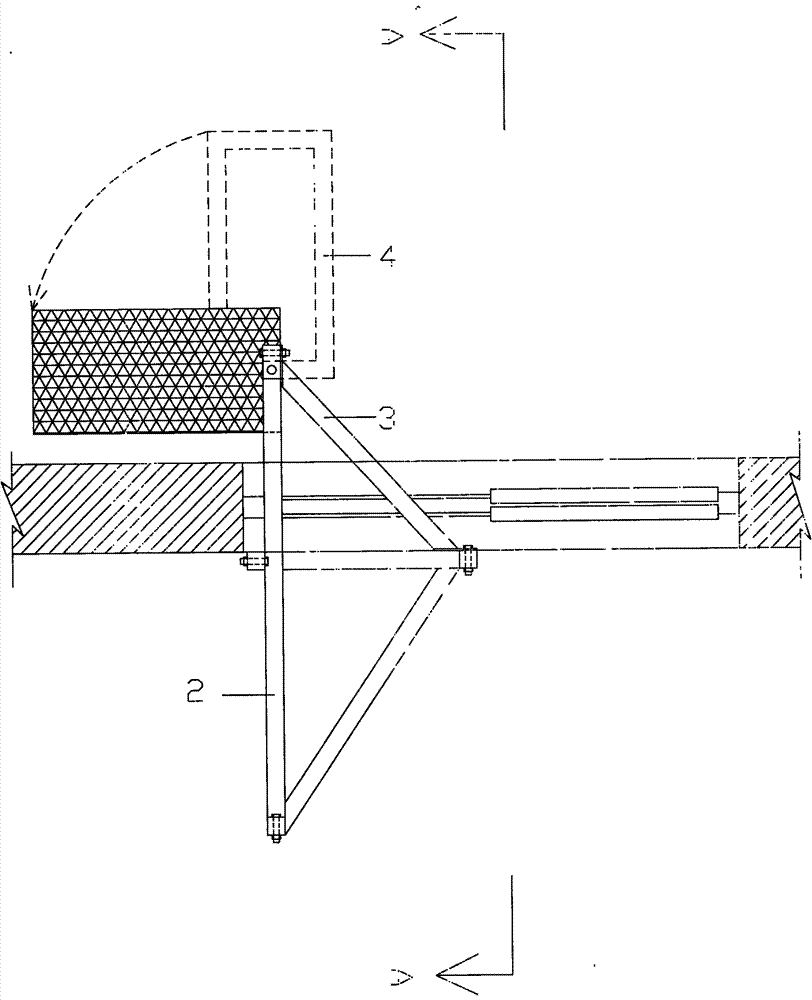

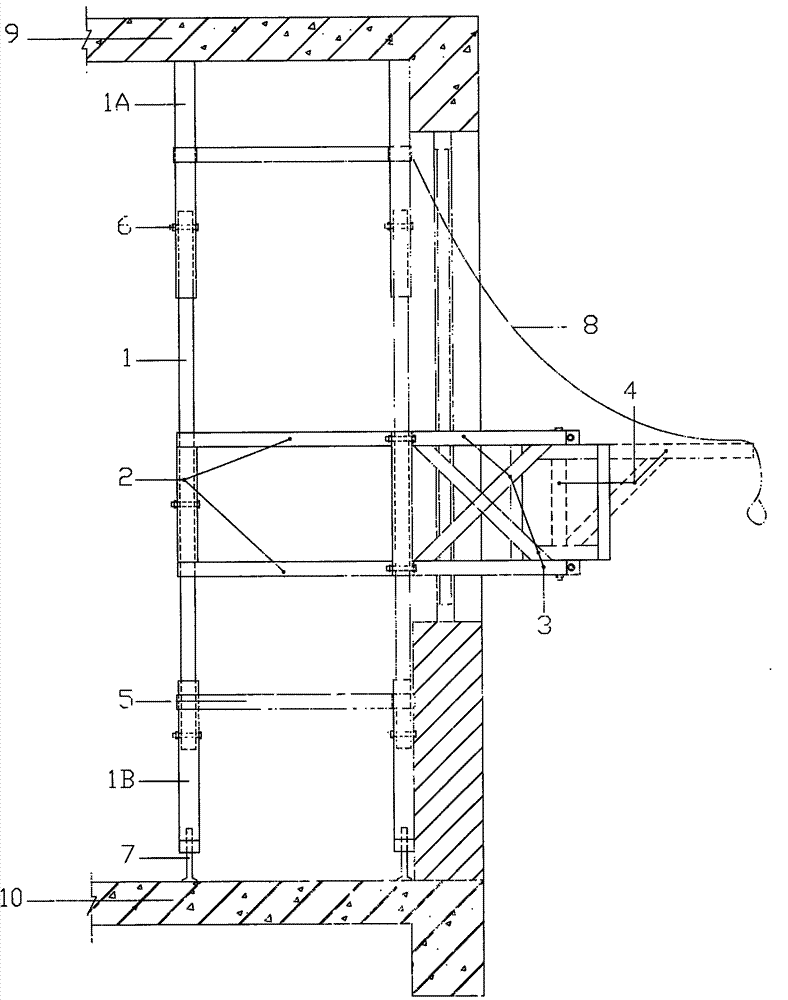

[0013] According to the above description, the present invention will be described in detail below in conjunction with the accompanying drawings

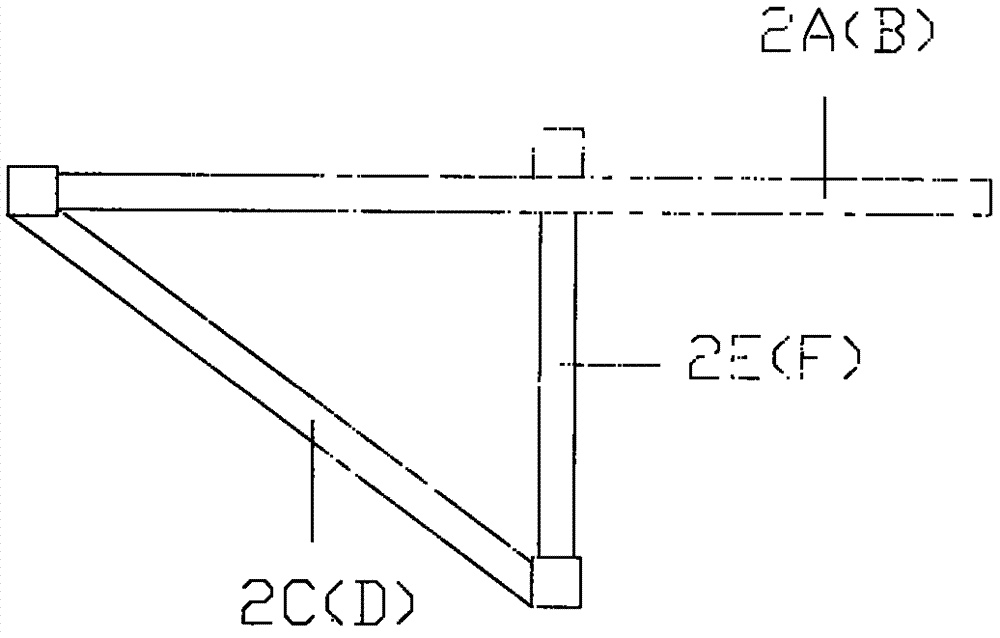

[0014] Such as figure 2 As shown, the middle section 1 of the vertical rod is inserted into the unit member 2 of the horizontal rod 2A, 2B, 2C, 2D, 2E, and 2F that bears the extended rotating operation platform, and the horizontal rod 5A , 5B, and 5C are respectively inserted into the upper section 1A and the lower section 1B of the vertical bar to strengthen the force system, and then the two ends of the middle section 1 of the vertical bar are respectively inserted into the upper section of the vertical bar In 1A and the lower section 1B, the positioning height of the pin bolt 6 is interspersed, and the lifting bolt 7 at the bottom of the lower section of the vertical rod is tightened, so that the two ends of the entire vertical rod are in close contact with the roof surface 9 and the floor surface 10 respectively, and are instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com