Reusable pipe formwork hanging fastening device

A technology of fastening device and hanging formwork, applied in formwork/formwork/work frame, on-site preparation of building components, connection of formwork/formwork/work frame, etc. Use, low work efficiency and other problems, to achieve the effect of improving work efficiency, reducing material costs, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

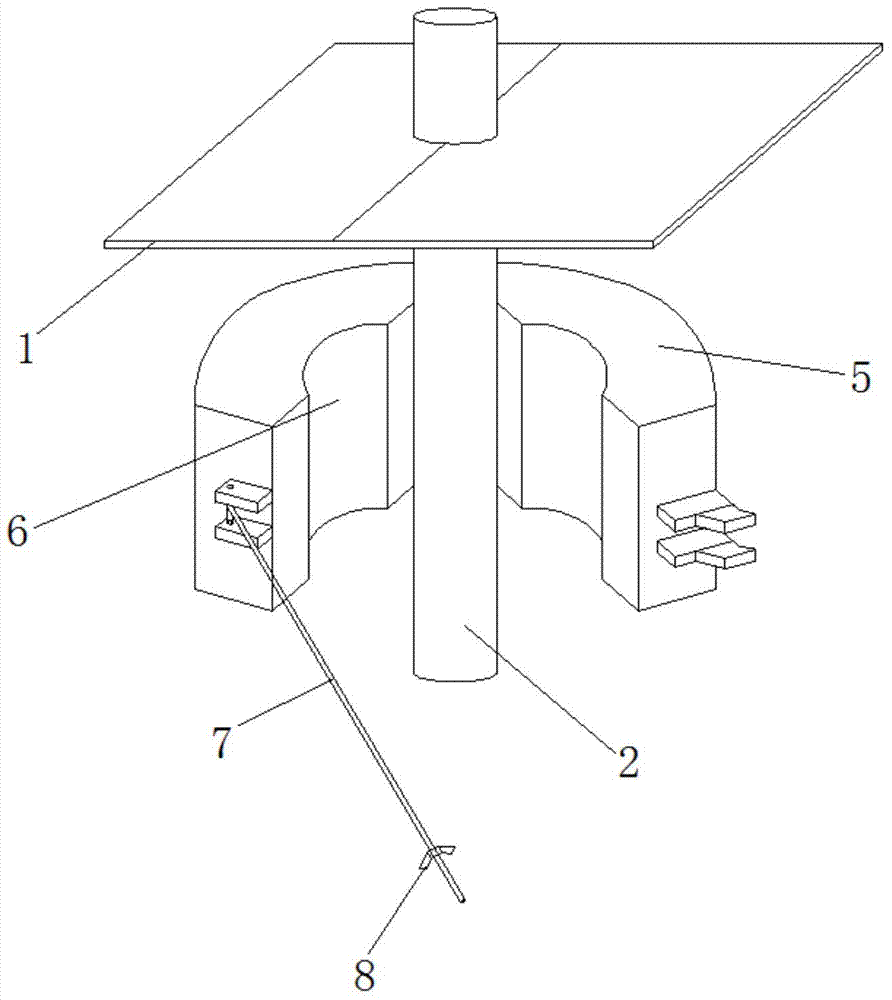

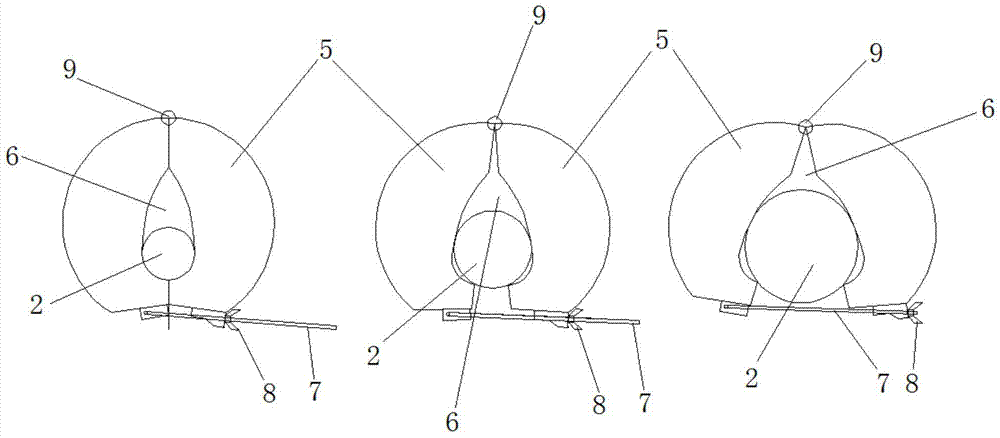

[0013] Such as figure 2 , 3 As shown, the reusable pipe hanging mold fastening device includes two semicircular clamp arms 5, one end of the two semicircular clamp arms 5 is connected together by a hinge 9, and the other end of the clamp arm 5 is connected by a lock, and the lock Including screw rod 7, one end of the screw rod 7 is movably connected to a clamp arm 5, and the other end is connected to another clamp arm 5 through a lock nut 8; a drop-shaped clamping device is arranged between the two semicircular clamp arms 5 Hole 6.

[0014] Such as image 3 As shown, the drop-shaped clamping hole 6 can be adapted to pipes 2 with different diameters.

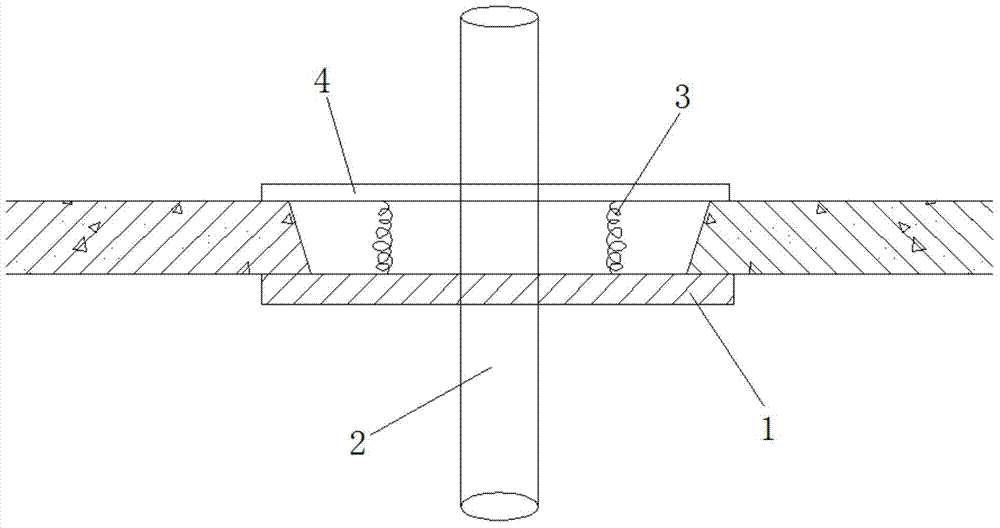

[0015] After the wooden formwork 1 of pouring concrete is placed, the device of the present invention is clamped on the pipeline 2 under the wooden formwork 1, and the present invention can withstand the wooden formwork 1 without pulling the wooden formwork 1 by iron wire.

[0016] The installation and disassembly of the dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com