Temporary subsea base and method for mass installation of deepwater surface conduits

A technology of template and conduit, which is applied in the direction of drill pipe, casing, earthwork drilling, etc., can solve problems such as low work efficiency, affecting installation accuracy, impacting conduit, etc., and achieves easy maintenance, improved working time, and guaranteed positioning accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

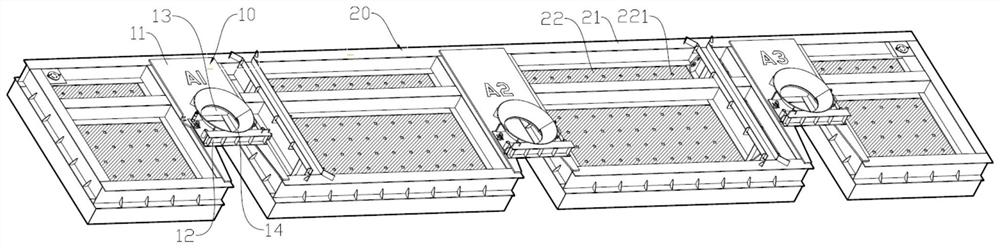

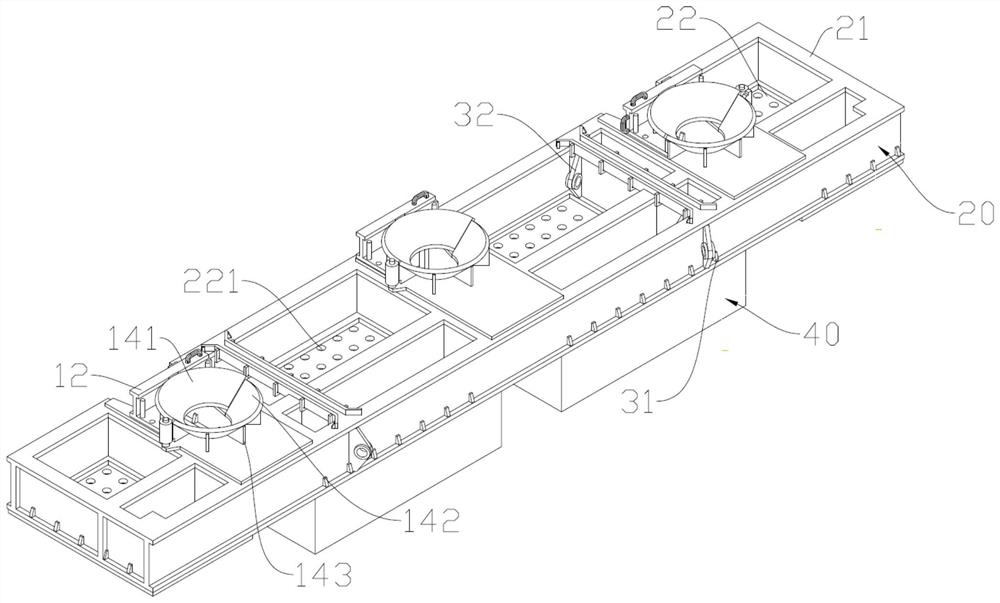

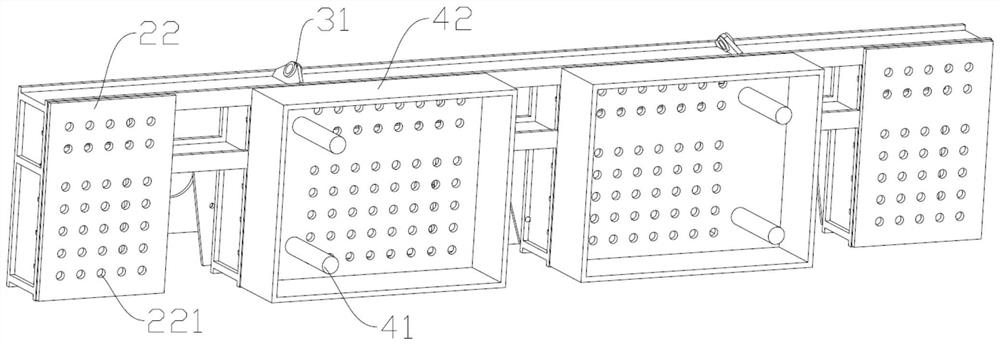

[0032] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0033] In the present invention, in order to make the language concise, the conduits mentioned in this article are all deep-water surface conduits, and the bases mentioned are all temporary submarine bases, which will not be repeated in the following.

[0034] In the development of deepwater oil and gas fields, multiple deepwater surface conduits need to be installed, and the installation accuracy of the conduits is usually very high. Usually, the conduits need to be positioned and installed in sequence, which is very inefficient, and it is easy to collide during the process of positioning and installing the conduit. Other pipes that have been inserted into the mud will cause the position of the pipes that have been inserted into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com