Glass engraving fixing device

A fixing device and glass technology, applied in the direction of work accessories, stone processing equipment, manufacturing tools, etc., can solve the problems of poor fixing effect and waste of work time for workpieces, and achieve the effect of improving work time and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

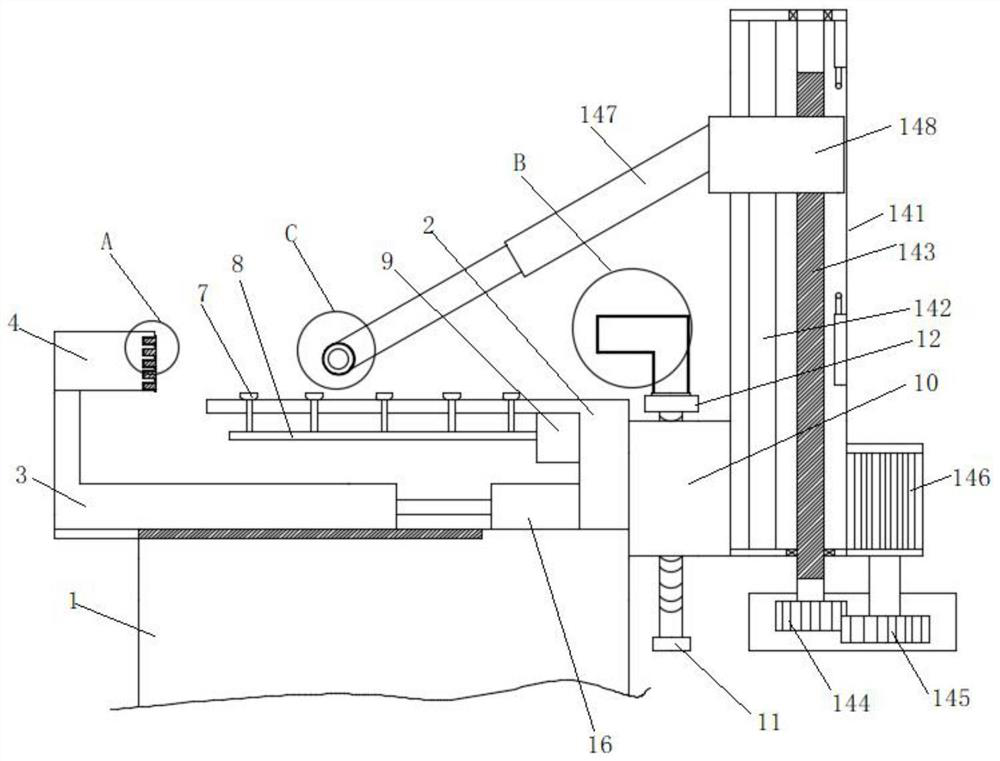

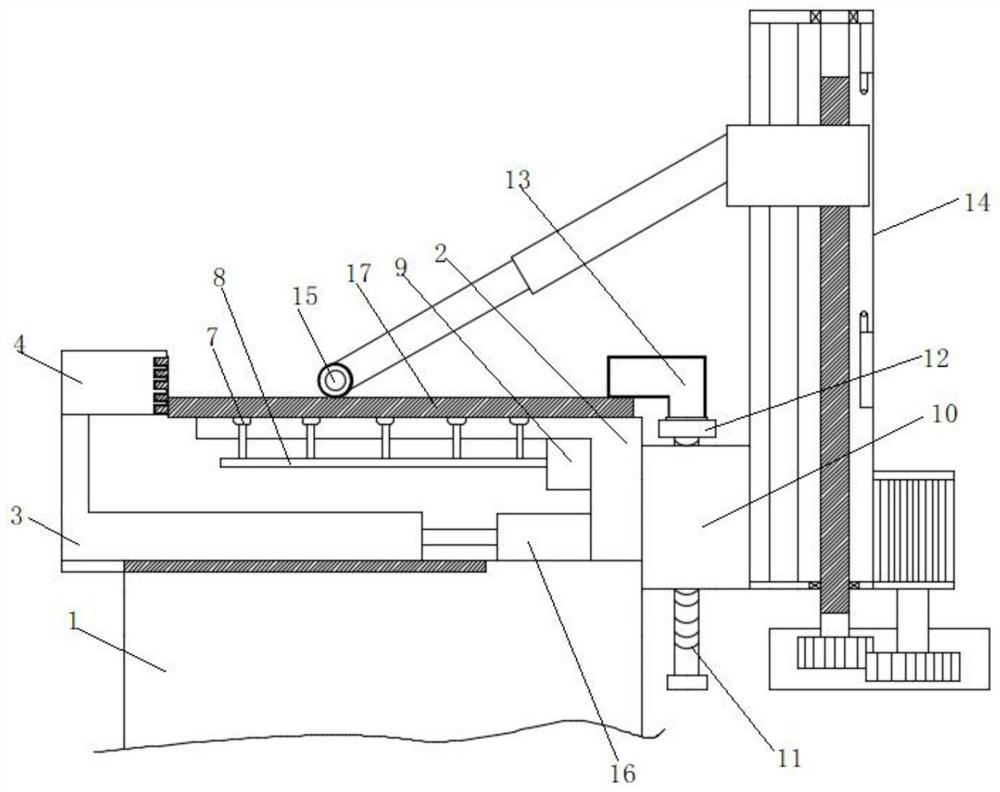

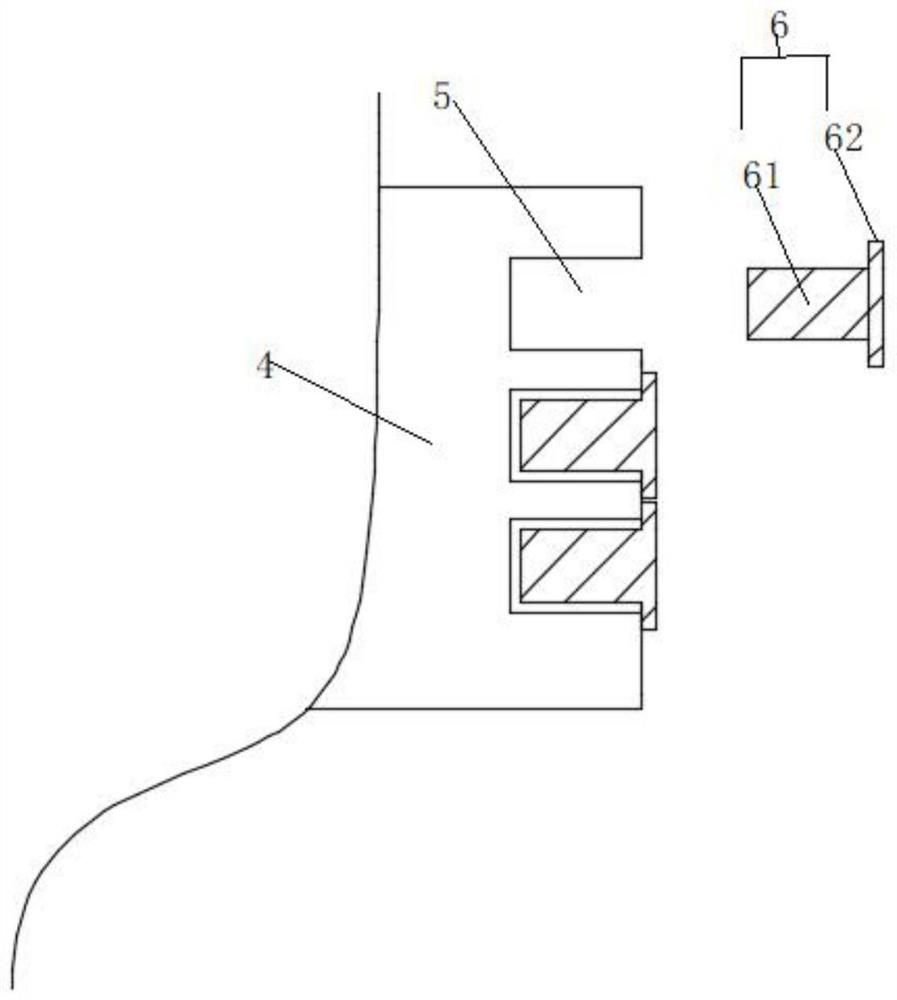

[0034] Implementation case 1: Place the glass 17 on the operating table 2, start the negative pressure generator 9, and the negative pressure generator 9 will vacuum the space between the glass 17 and the negative pressure suction cup 7 to realize the adsorption of the glass 17 and complete the preliminary fixation. Move the electric telescopic device 16, and the moving block 3 slides in the chute, so that the buffer pad 6 touches the glass 17, so that one side of the glass 1 is fixed, and the movable rod 11 is manually rotated. Some internal threads make the clamping block 13 move to the top of the glass, and adjust the direction of the direction head 12, so that the clamping block 13 is clamped on one side of the glass 17, start the motor 146, and the motor 146 drives the driving gear 145 to rotate, and the driving gear The driven gear 144 connected by 145 rotates, and the driven gear 144 drives the threaded rod 143 to rotate, so that the sliding block 148 slides. After the s...

Embodiment example 2

[0035] Implementation example 2: when the movable rod 11 is provided with an elastic button latch head 111 and the fixed box 10 is provided with a latch hole 112, since the fixed block 10 is provided with a longitudinal row of latch holes 112, press the elastic button latch head 111 , and rotate the movable rod 112 to realize the adjustment of the clamping block position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com