Perforation angle variable perforator for oil-gas well perforation

A technology of oil and gas wells and perforators, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the problem that the operation of variable angle cannot be performed, and the perforator cannot meet the purpose of perforating sand control in oil and gas wells, and cannot realize Problems such as oil and gas well orientation function, to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

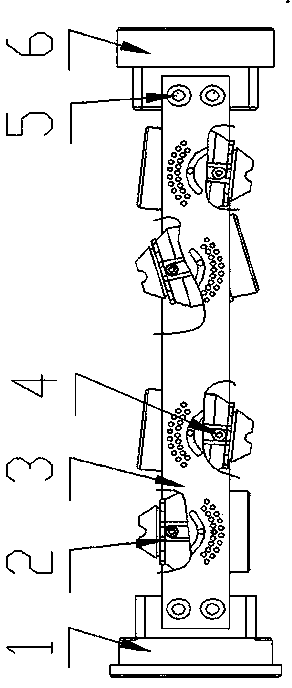

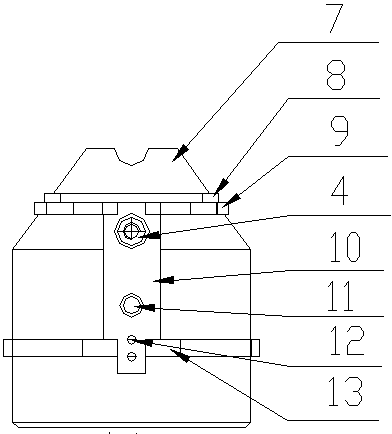

[0054] As a preferred embodiment of the present invention, the present invention discloses a variable firing angle perforator for perforating oil and gas wells, which includes a modular bullet rest device 2 and a directional steel structure 3 matched with the modular bullet rest device 2, A perforating charge 7 is installed in the modular bullet support device 2;

[0055] The modular bullet support device 2 includes an upper bullet support plate 13, a lower bullet support plate 9 and two bullet support plates 10, and the upper bullet support plate 13 and the lower bullet support plate 9 are provided with holes for matching the outer diameter of the perforating charge 7. Matching bullet holes 17, the upper bullet support plate 13 and the lower bullet support plate 9 are connected and fixed by the bullet support support plate 10. The bullet support support plate 10 is connected with the hinge shaft 4 and the chute pin 11. At least one indexing fixing hole 12 is also processed on...

Embodiment 2

[0058] As another preferred embodiment of the present invention, on the basis of Example 1, the hinge shaft hole 36, the adjustment chute 35 and the arc-shaped indexing hole 37 on the orientation square structure 33 are distributed in groups, and two adjacent groups The perforation direction of the perforating charge 7 in the modular bullet rest device 2 is opposite and adjustable. There are two rows of indexing holes 37 arranged on the orientation square structure 33 . The orientation square structure 33 is plate-shaped.

[0059] Fixed ring 1 comprises circular head 38, is provided with two fixed plates 39 arranged in parallel on circular head 38, two fixed plates 39 and head 38 vertical and integrated molding, on two fixed plates 39 Pin holes 40 are processed, and the two fixing plates 39 are respectively fixed on the two directional square structures 33 via the fixing pins 5 , and steps are arranged on the circular head 38 .

[0060] Backing ring 6 comprises circular head...

Embodiment 3

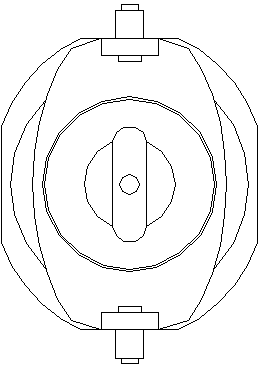

[0062] As the best implementation mode of the present invention, on the basis of Example 2, there are two indexing fixing holes 12 on the bullet support plate 10 . The upper part of the perforating charge 7 is cylindrical, and the lower part is in the shape of an inverted truncated cone. A step 31 and a limiting groove 32 are provided on the lower part of the perforating charge 7 in the shape of a truncated cone. The lower bullet support plate 9 is embedded in the limiting groove 32 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com