A floating bearing cylinder

A floating support and oil cylinder technology, applied in the field of support oil cylinders, can solve the problems of shortened service life, high ball receiving stress, short service life, etc., and achieve the effect of improving support force and large support force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

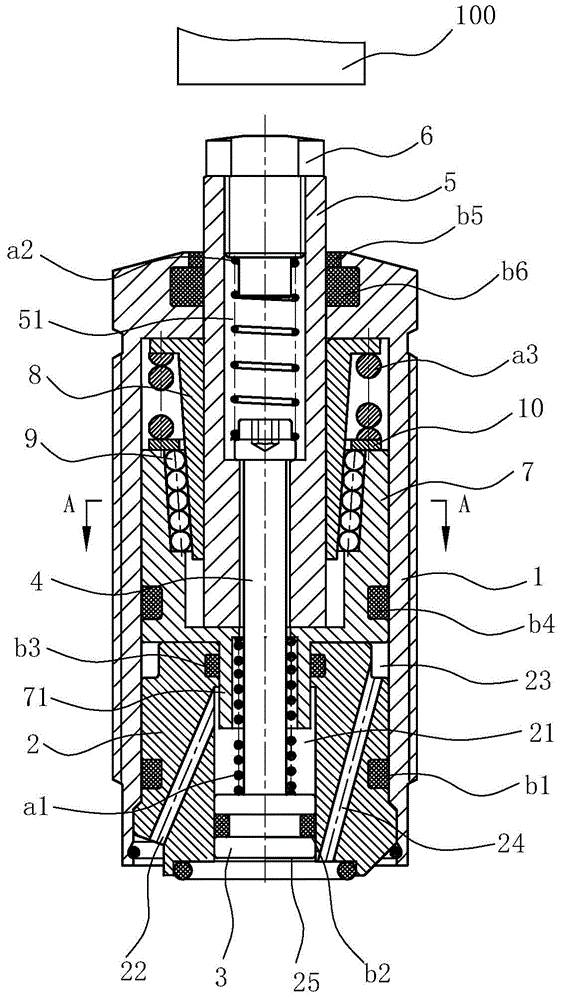

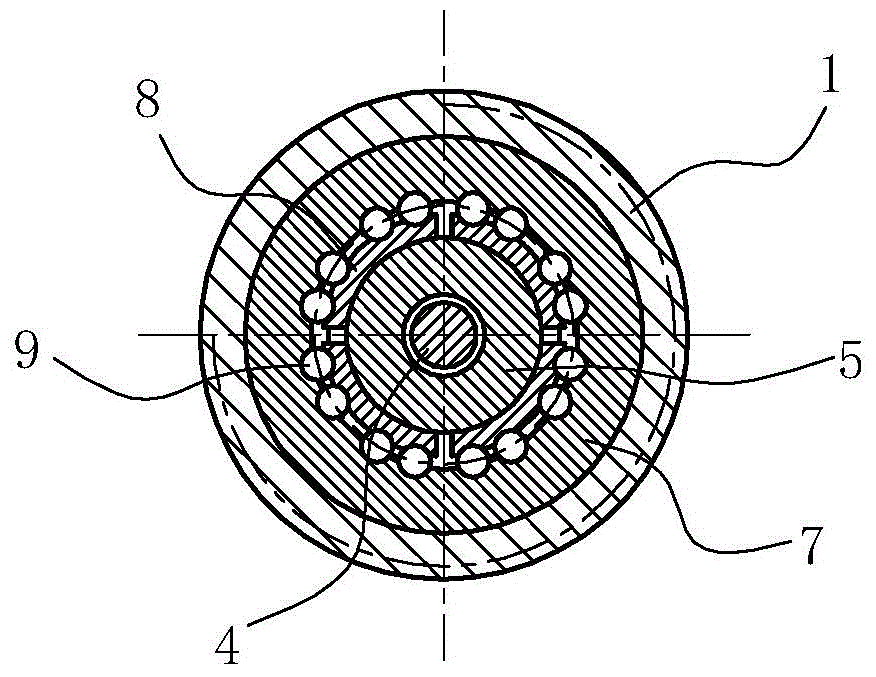

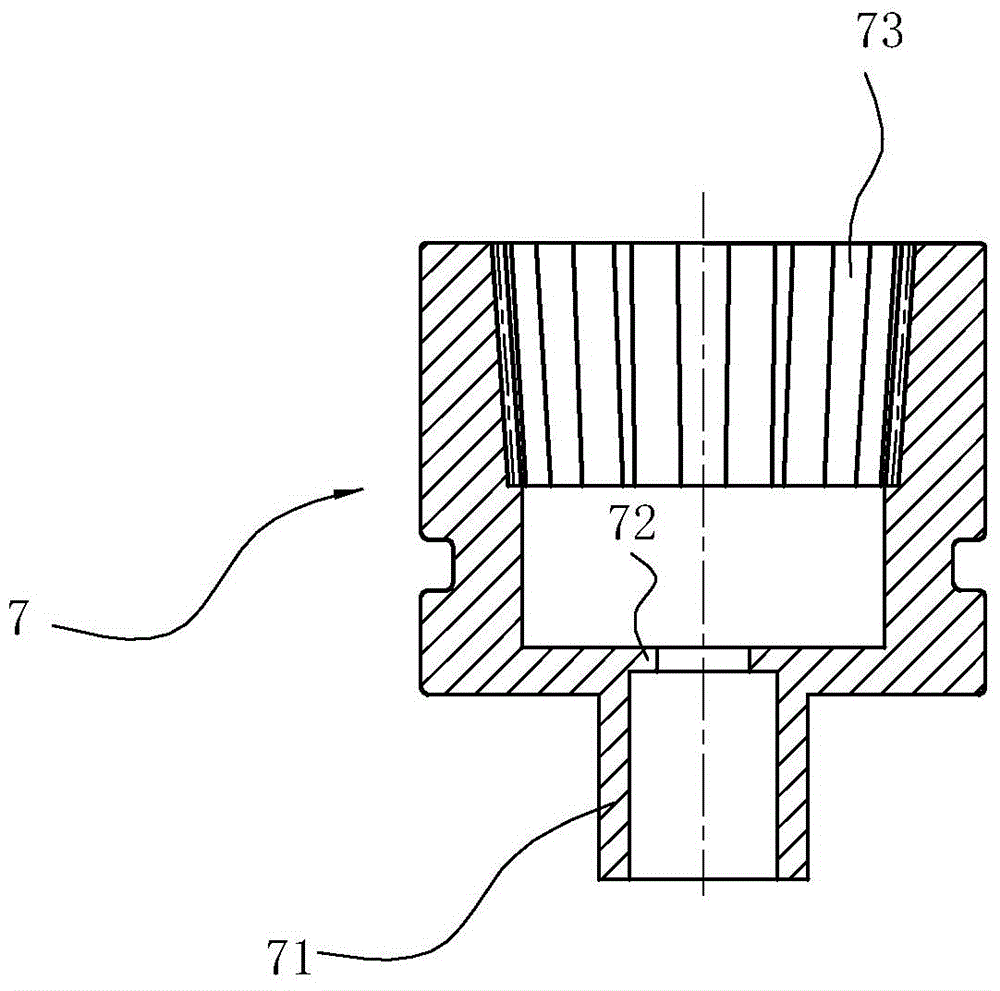

[0026] The first embodiment: as Figure 1 to Figure 6 As shown, the hydraulic floating support cylinder in this embodiment includes a cylinder body 1, an ejector device and a support clamping device, wherein the inner diameter of the cylinder body 1 is 24 mm, the outer wall has external threads, the upper end surface has a through hole, and the lower port is open. The ejector device includes a base 2, an ejector piston 3, an ejector rod 4, a return spring a1, a support rod 5 and an ejector spring a2, and the base 2 is positioned in the lower port of the cylinder body 1, and the base 2 and the cylinder 1 is provided with a first sealing ring b1, so that the base 2 is sealed and blocked in the lower port of the cylinder 1; the base 2 is also provided with a piston channel 21 in the axial direction. In this embodiment, the piston channel The diameter of the upper part of 21 is smaller than the diameter of the lower part, and the above-mentioned ejector piston 3 is located in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com