Table-board supporting device for overlarge spliced platform

A support device and platform technology, applied in the field of support foot structure, can solve the problems of no auxiliary support, limited adjustment accuracy of hydraulic mechanism, and low adjustment accuracy, so as to achieve rapid adjustment of inclination and height, overcome foundation settlement deviation, and rapid positioning and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further explain the technical means and functions adopted by the present invention to achieve the intended invention purpose, the structure, features and functions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

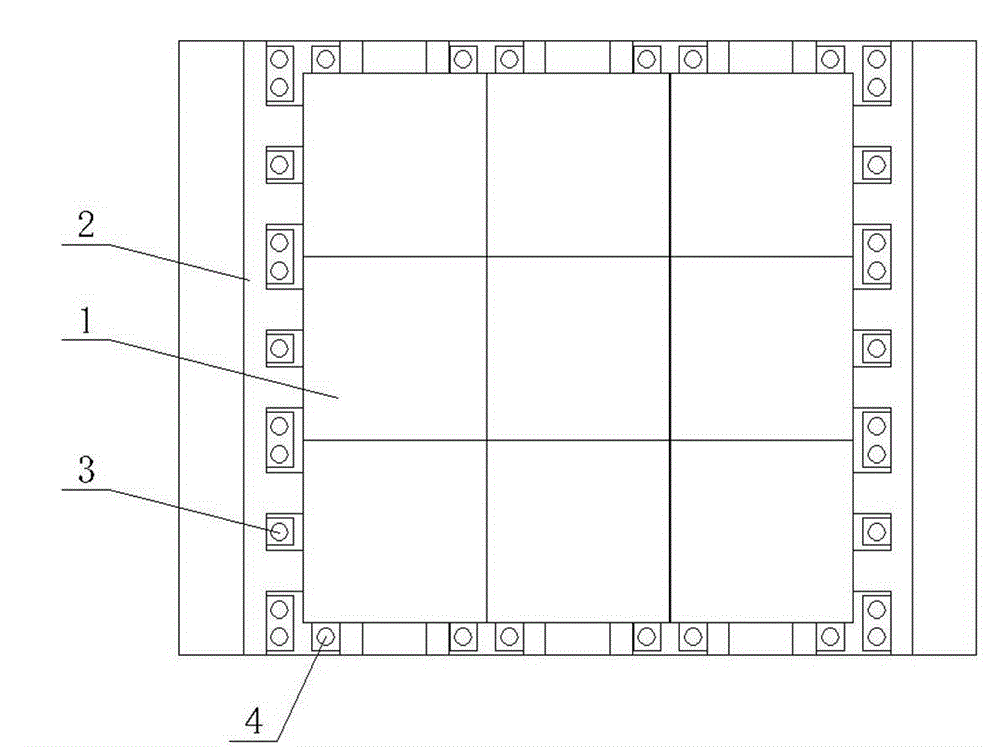

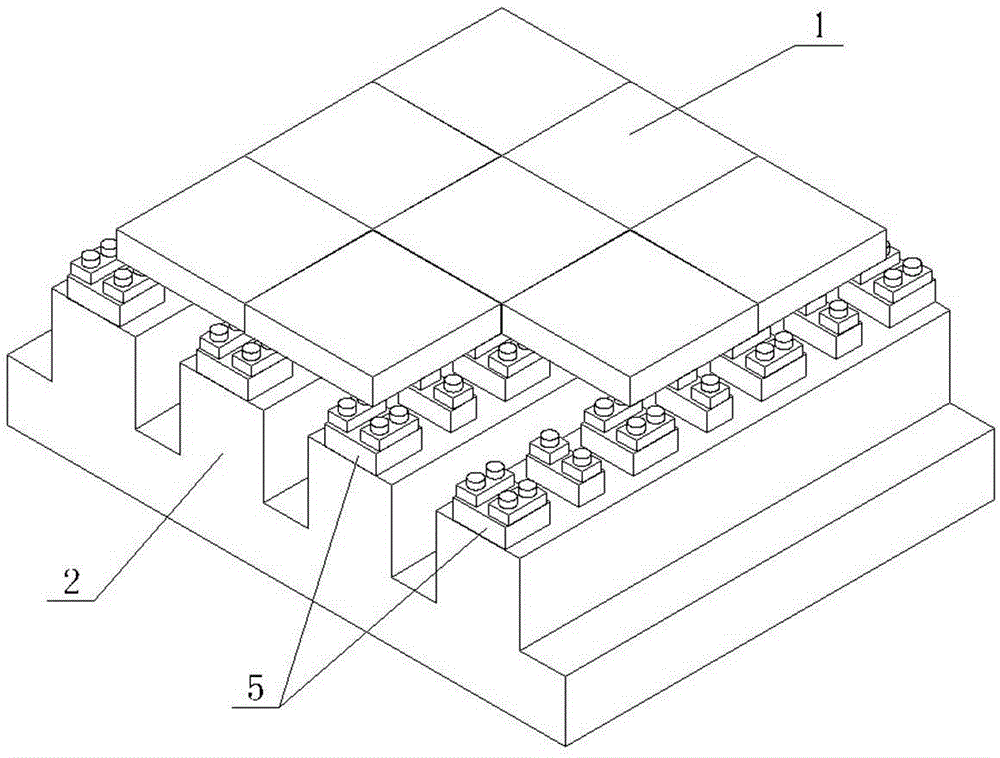

[0028] The super-large splicing platform applied in the present invention is as figure 1 , image 3 As shown, it is composed of several sub-platforms 1 spliced together. The sub-platform 1 is firmly supported on the base 2 through the active support foot 3 and the auxiliary support foot 4. The design requires a relatively large horizontal surface.

[0029] Such as figure 2 , image 3 , Figure 4 , Figure 5 Shown is one of the embodiments of the present invention. In this embodiment, a table support device for a super-large splicing platform is provided with 6 support feet with adjustable support heights for each sub-platform 1 of the splicing platform. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com