Power supply device for anchor rod production line

A power supply device and production line technology, applied in the direction of circuits, current collectors, electrical components, etc., can solve the problems of affecting power supply, poor contact, easy to burn carbon brushes, etc., and achieve good conductive effect, prevent series current, and precise connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following describes the present invention in further detail with reference to the accompanying drawings and embodiments, but it is not intended as any limitation to the present invention.

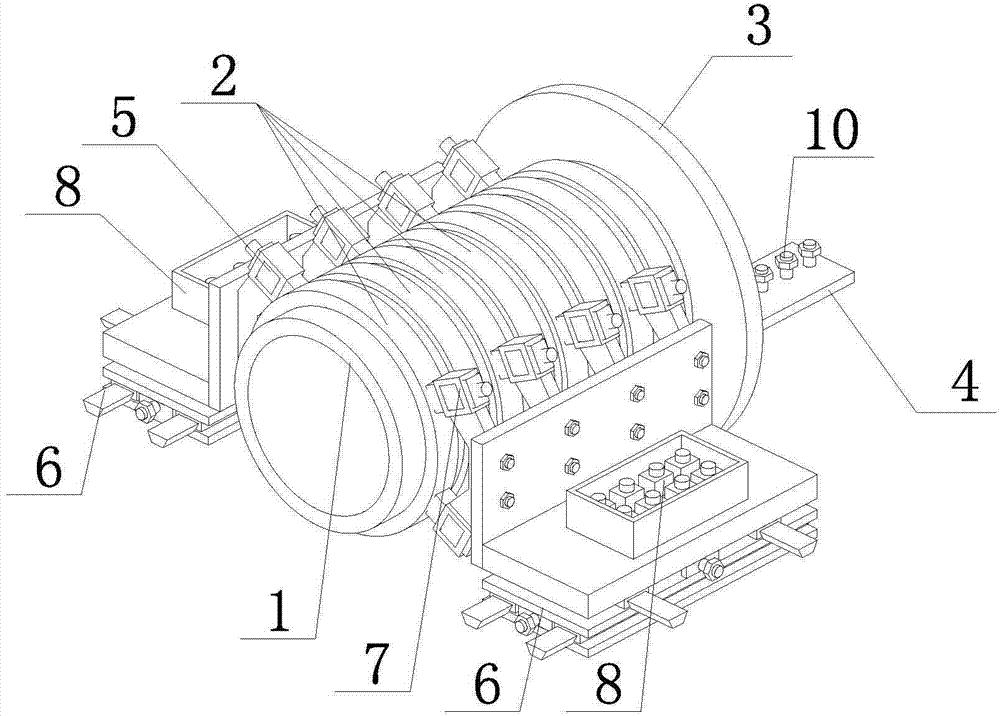

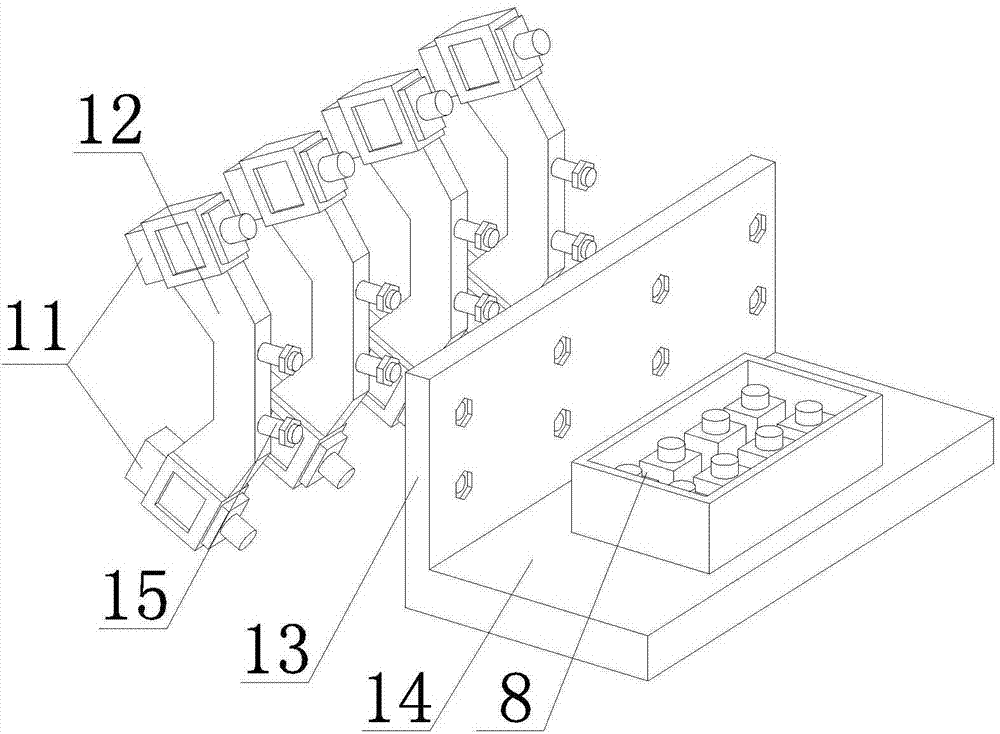

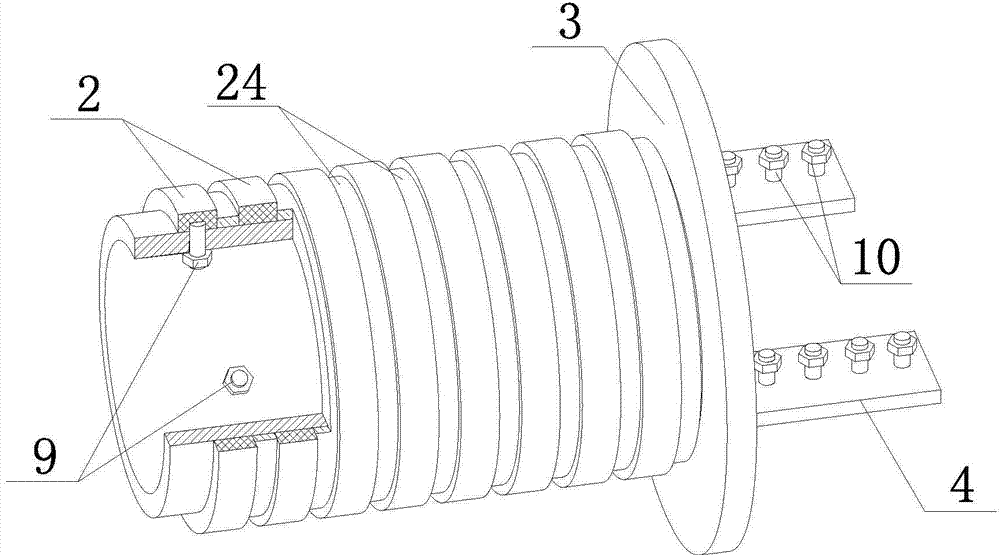

[0018] Examples of the present invention, such as figure 1 with image 3 As shown, a power supply device for an anchor rod production line includes an insulating tube 1, a conductive ring 2, a turntable 3, a mounting plate 4, a carbon brush set A5, a carbon brush set B7, and a position adjustment device 6. The conductive ring 2 is set in On the outer circle of the insulating tube 1, the turntable 3 and one end of the insulating tube 1 are connected by threads, and the mounting plate 4 is fixed on the turntable 3. The carbon brush set A5 and the carbon brush set B7 are symmetrically arranged on both sides of the insulating tube 1 to set The end with the turntable 3 is the starting end, the odd-numbered conductive ring 2 is slidingly connected to the carbon brush group A5, and the even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com