Construction method of alternating-current magnetic bearing fault-tolerant decoupling controller

A technology of decoupling controller and construction method, applied in the field of magnetic levitation transmission, to achieve the effect of good application value and popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The concrete implementation of the present invention divides following 10 steps:

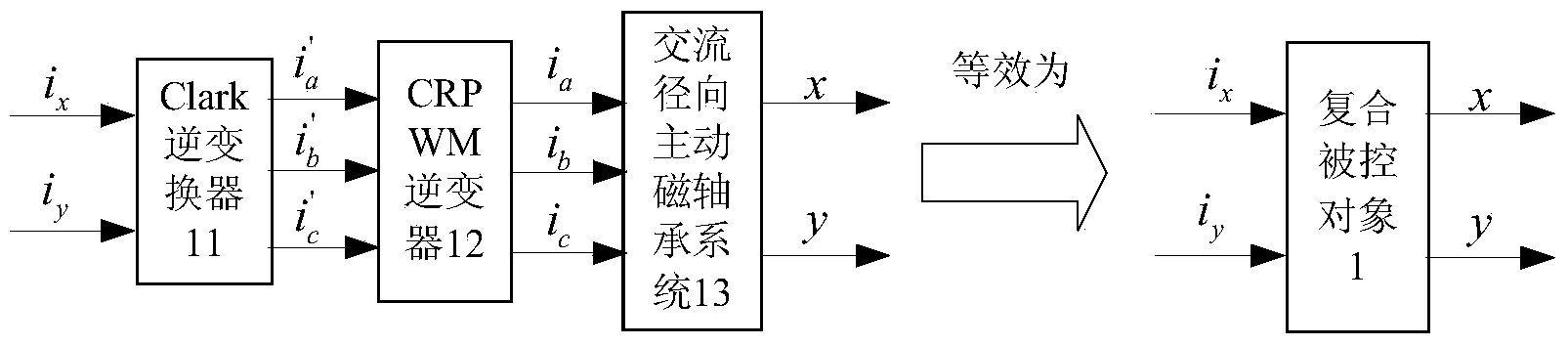

[0022] 1. Connect the Clark inverter 11 and the CRPWM inverter 12 in series before the AC radial active magnetic bearing system 13 to form a compound controlled object 1, such as figure 1 shown. The compound plant 1 starts with {i x ,i y}Two control current signals are taken as input, and the radial displacement x and y of the rotor are taken as output.

[0023] 2. Based on the levitation operation principle of the AC radial active magnetic bearing, establish the mathematical model of the non-AC radial active magnetic bearing system 13, and obtain the mathematical model of the composite controlled object 1 through the Clark inverse converter 11 and the CRPWM inverter 12 model, analyze the reversibility of the mathematical model, and prove that the mathematical model is reversible, that is, there is an inverse model.

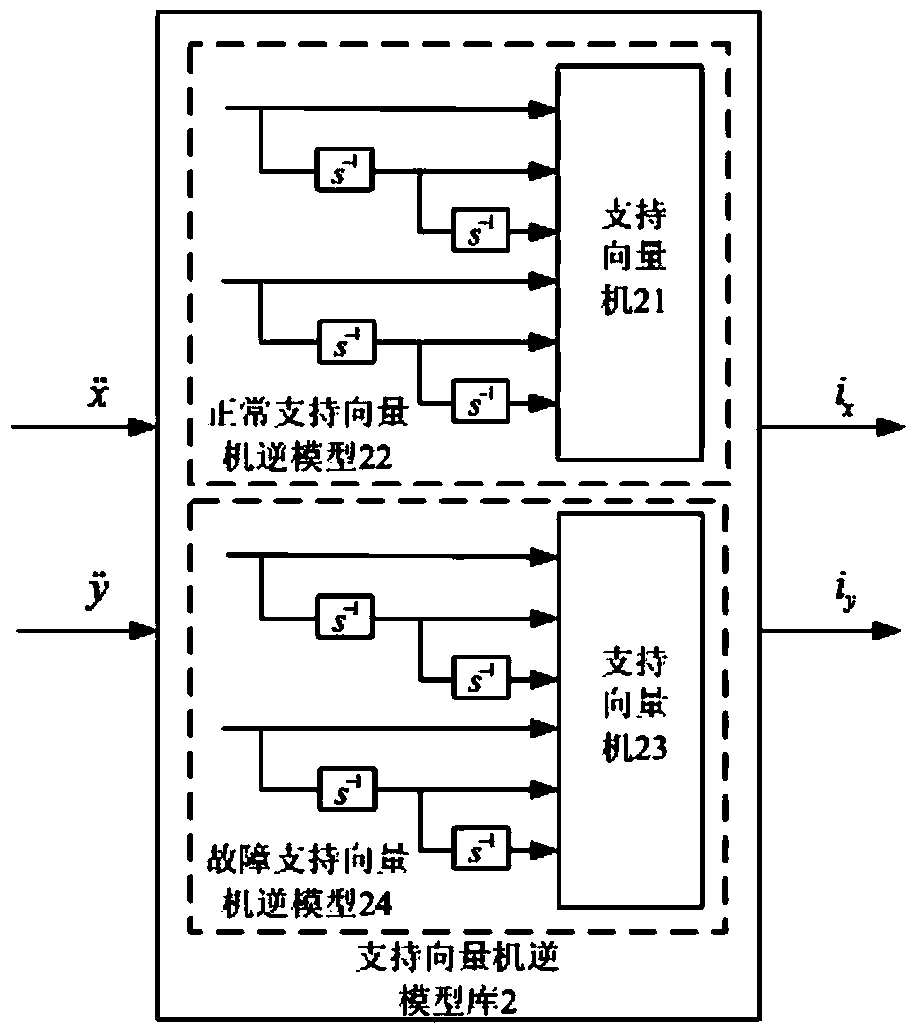

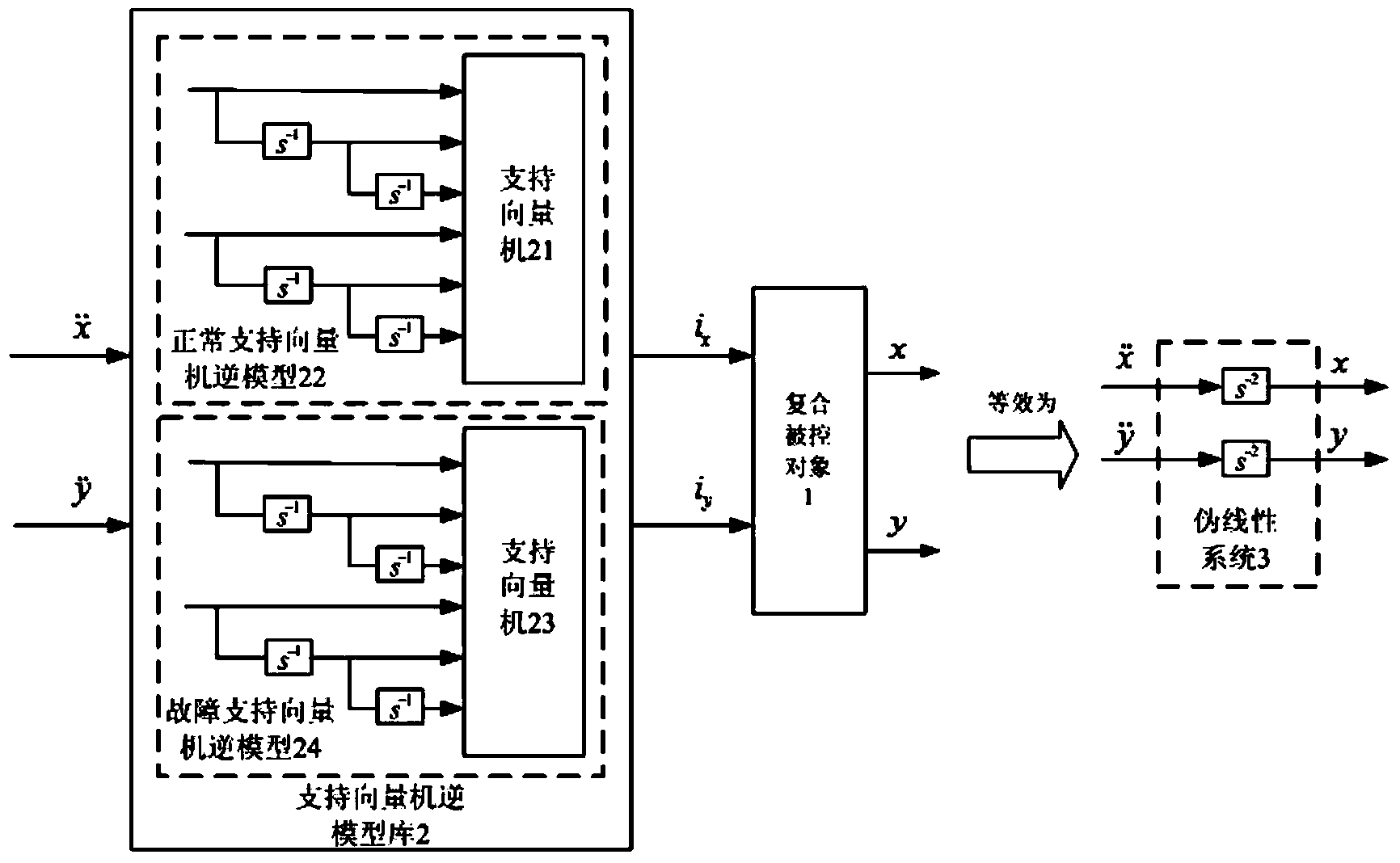

[0024] 3. Adopt a support vector machine 21 with 6 input nodes, 2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com