Filter sealing plate continuous punch forming die and feed mechanism

A technology of stamping forming and feeding mechanism, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of high equipment manufacturing cost, low work efficiency and high labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

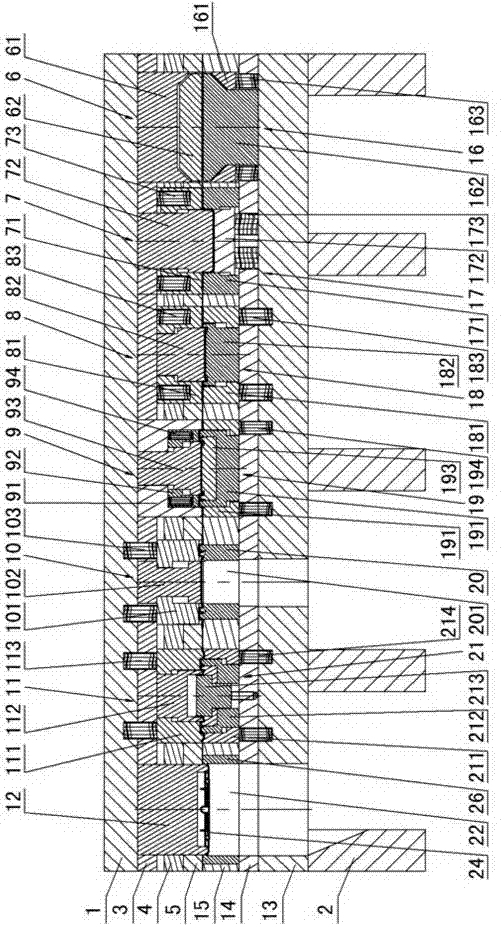

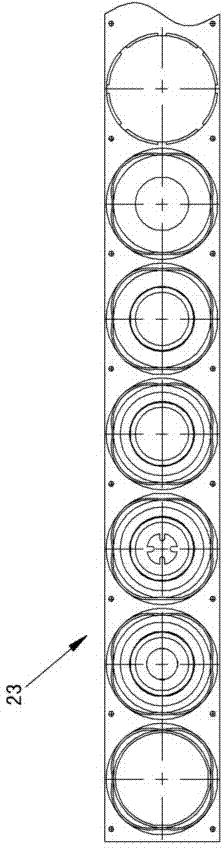

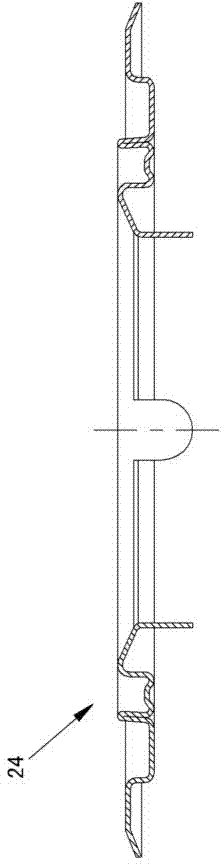

[0014] The invention relates to a continuous stamping mold and a feeding mechanism for a filter sealing plate, such as figure 1 — Figure 7As shown, it is characterized in that it includes an upper formwork 1 and mold feet 2, a fixed plate 3 is installed under the upper formwork, a stripping ring backing plate 4 is installed under the fixing plate, a stripping ring plate 5 is installed under the stripping ring backing plate, and The fixed plate under the upper template 1, the stripping ring backing plate and the stripping ring plate are successively equipped with a cutting ring upper die 6, a stretching upper die 7, a first molding upper die 8, and a second molding upper die 9 , punching upper die 10, turning hole upper die 11 and stripping module 12, described cutting ring upper die 6 includes cutting ring upper die base 61 and cutting ring upper die core 62, and described stretching upper die 7 includes stretching Upper die base 71 and stretching upper die core 72, stretchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com