New type mixer truck receiving device

A technology of a material receiving device and a mixer truck, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as troublesome pouring of overflowing materials, baffle overflowing, and inability to completely prevent mortar overflowing, etc. The effect of pouring the overflow is convenient and preventing the overflow from spilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

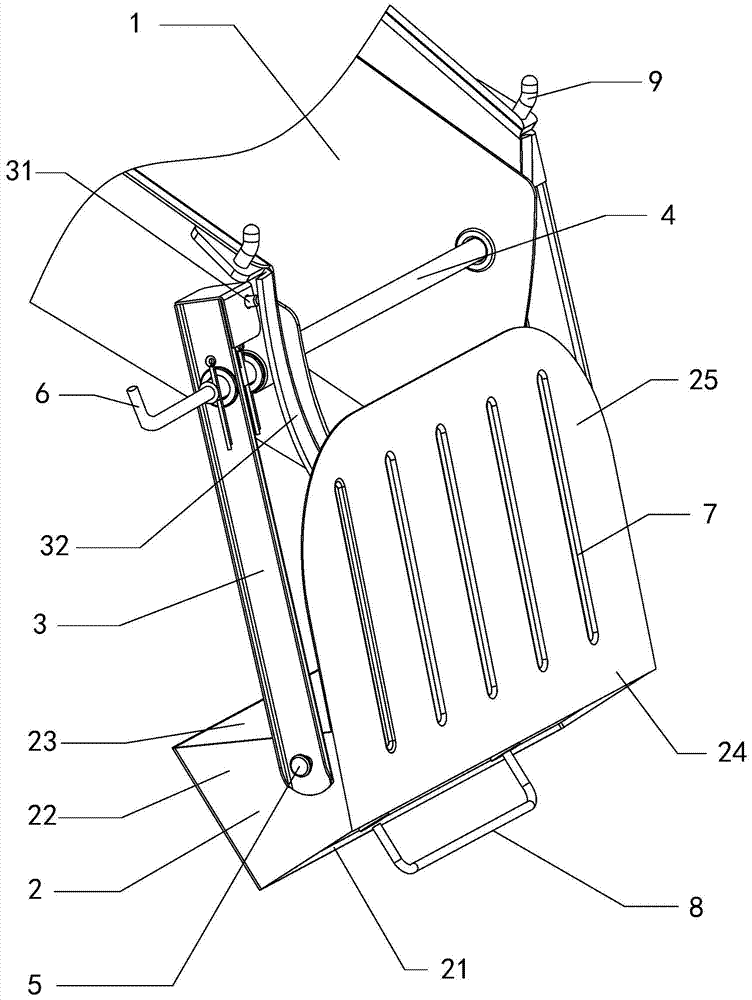

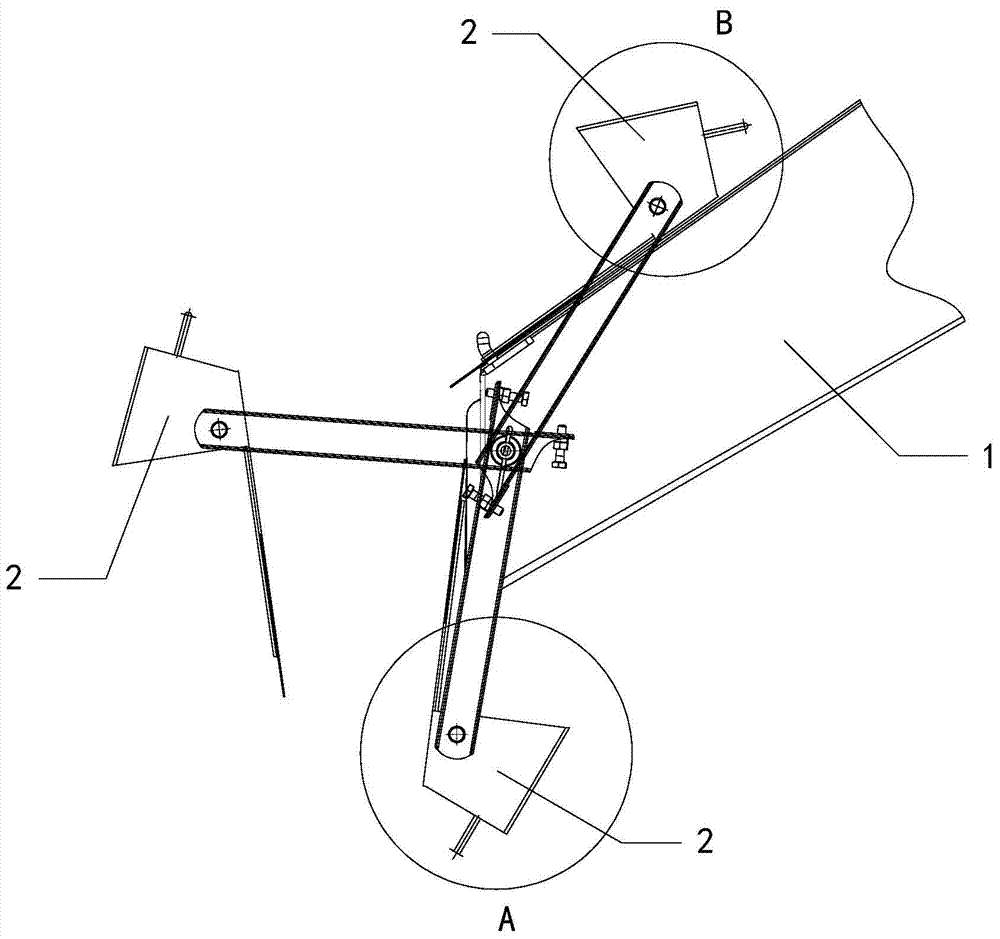

[0021] Such as figure 1 As shown, the novel mixer truck receiving device of the present invention comprises a U-shaped unloading chute 1, a receiving hopper 2 and a connecting arm 3, and the receiving hopper 1 is composed of a base plate 21, two side plates 22, a back plate 23 and a front plate 24 to form a box-shaped receiving hopper, the front plate extends outwards to be a baffle plate 25, the angle between the bottom plate 21 and the front plate 24 is greater than 90°, and one end of the two connecting arms 3 is fixed on the discharge plate through the first rotating shaft 4. The side wall of the tank 1 and the other end are all fixed on the side plate 22 through the second rotating shaft 5. The receiving hopper 2 has a first working position A. In the first working position, the center of gravity of the receiving hopper 2 and the material blocking plate 25 are respectively located On the front and rear sides of the second rotating shaft 5, the opening of the receiving hop...

Embodiment 2

[0032]The novel mixer truck feeding device of the present invention can be realized in the following manner: the angle between the bottom plate 21 and the front plate 24 is 113.3°, the angle between the bottom plate 21 and the back plate 23 is 90°, the width of the hopper and the discharge trough The same is 60cm, the length of the backboard is 15cm, the linear distance between the top of the backboard and the material stopper is 16.65cm, the linear distance between the second rotating shaft and the material stopper is 3.15cm, and the vertical distance between the bottom of the handle and the top of the material stopper It is 42.56cm. If the receiving hopper is made of the same material, the horizontal distance between the center of gravity of the receiving hopper and the second rotating shaft is 3.11cm. The receiving hopper with this structure has been proved to have a good use effect by tests.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com