Method and apparatus for separating air by cryogenic distillation

A low-temperature distillation, air technology, used in lighting and heating equipment, cold process separation, refrigeration and liquefaction, etc., can solve problems such as impractical or impossible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

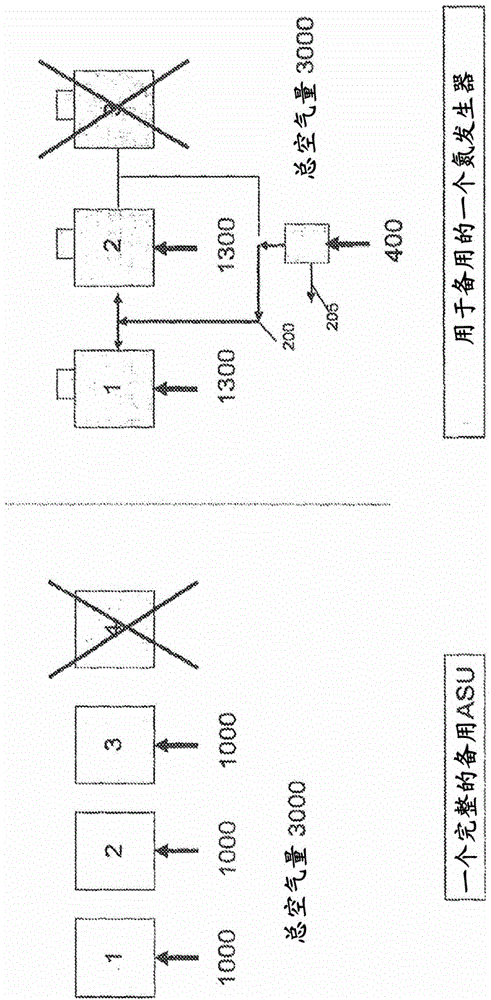

[0029] The new method of the present invention for increasing production based on low-cost storage purposes is in figure 1 Shown in. Compared with the traditional method in which a complete backup group is provided to ensure production, a simpler and lower cost nitrogen generator is proposed to replace the backup cold box. The nitrogen generator is designed to operate at a pressure similar to that of the oxygen generator (about 11 bar in the present invention) to ensure a simple compressor equipment reserve. However, other pressures can be used.

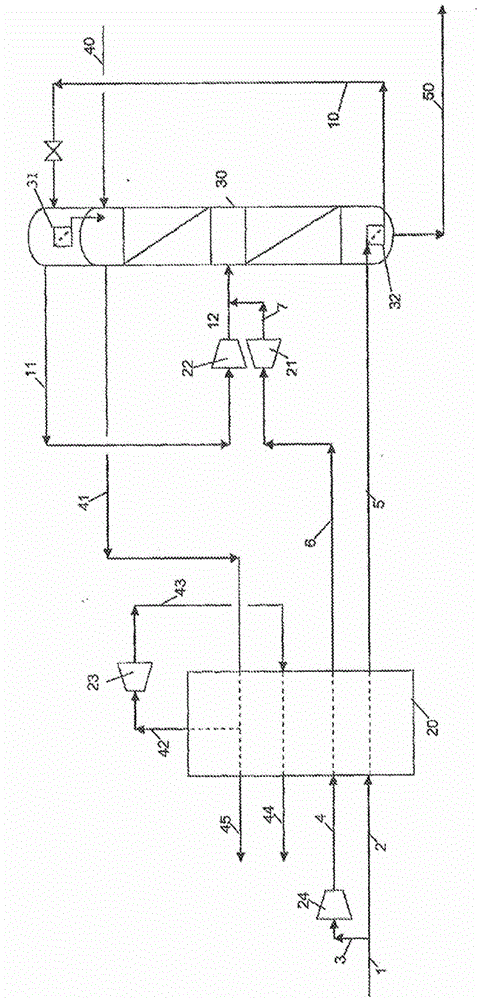

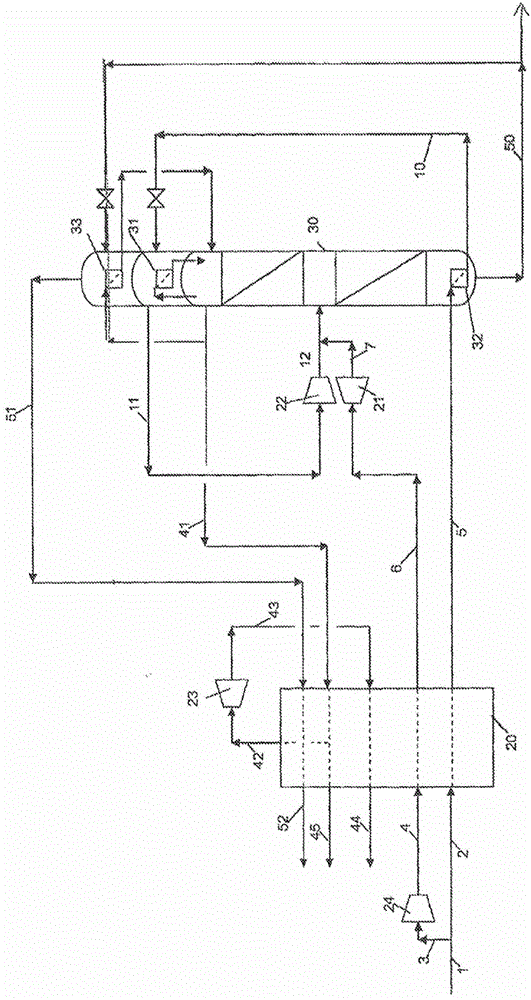

[0030] This storage concept using nitrogen generators can generally be applied to multi-group devices of low-temperature oxygen production equipment. In the following detailed description, the nitrogen generator synergy is similar to that of the present invention Figure 4 The process described in the cold box process layout. in figure 1 , The nitrogen generator separates the air into a nitrogen-rich stream 205 and a very rich / very c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com