Open pit smooth blasting powder charging device and operation method of open pit smooth blasting powder charging device

A smooth surface blasting and charging technology, which is applied in blasting and other directions, can solve problems such as package material damage, detonating cord twisting, charge string gun hole wall collision, friction, etc., to avoid damage, simple structure, and improve labor efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

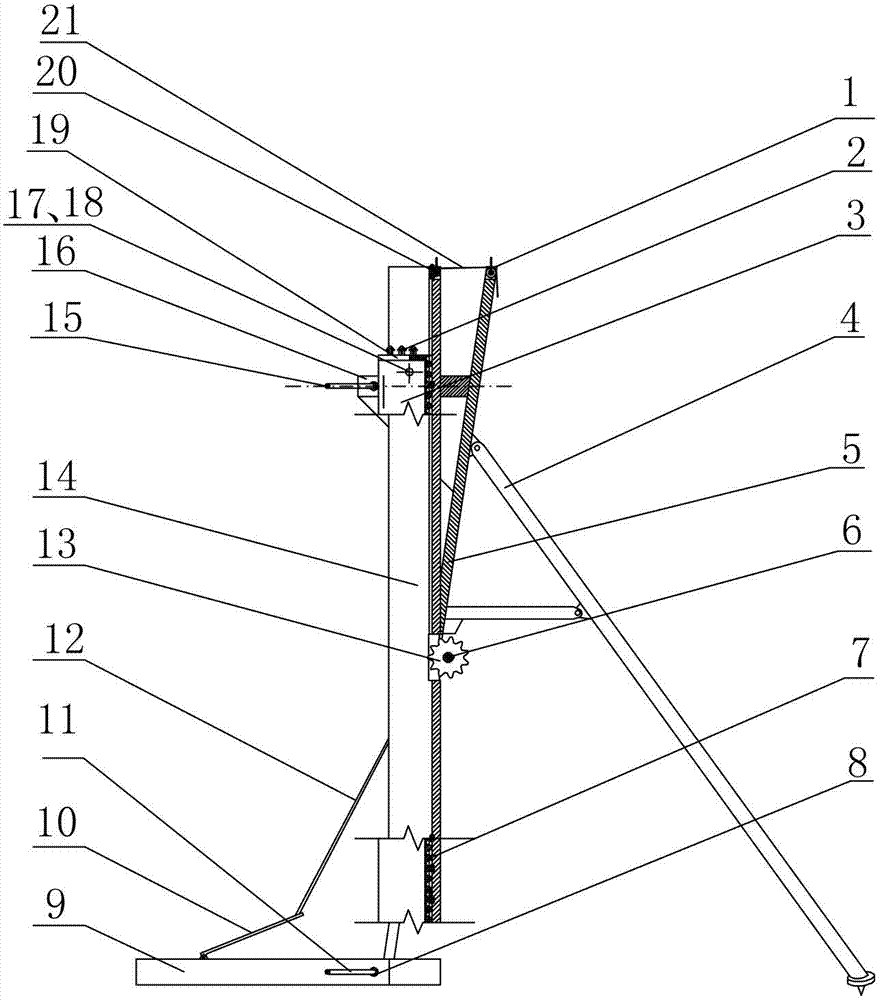

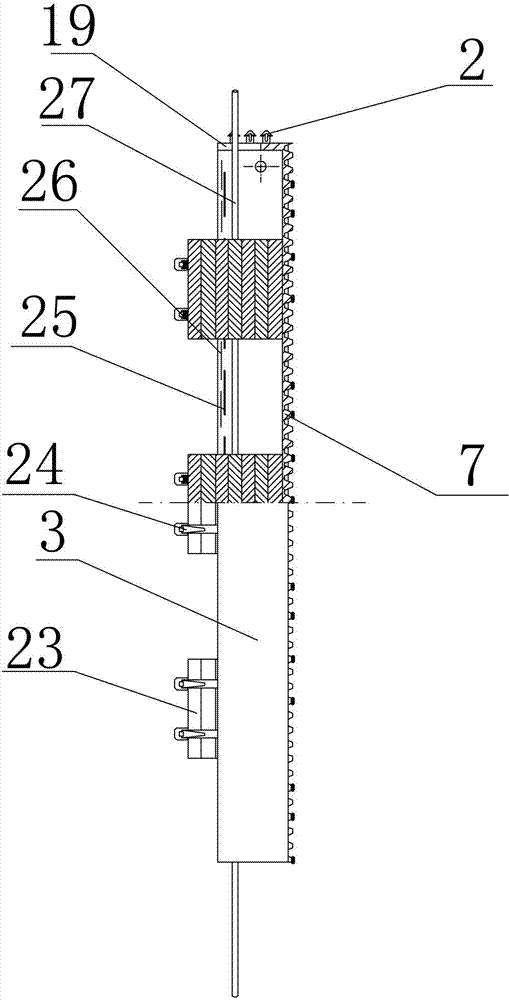

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, the open pit smooth surface blasting charge device of the present invention is characterized in that it is composed of a charge rack and a charge clamping device set in the charge rack,

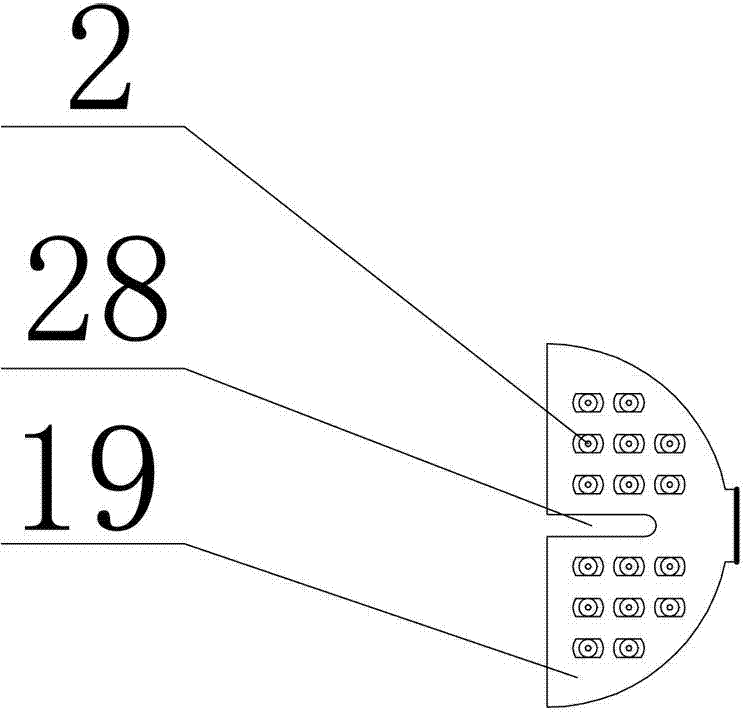

[0034] Described drug package fastening device is made up of semicircle clamping tube 3, the semicircle top plate 19 that is fixedly connected with described semicircle clamp tube 3 top, the rivet 2 that is fixedly connected with described semicircle top plate 19, and described semicircle clamp tube 3. The semicircular bottom plate 22 fixedly connected to the bottom, the connection hole 29 dug on the semicircular bottom plate 22, the strip-shaped seam 28 dug on the semicircular bottom plate 22 and the semicircular top plate 19, and the semicircular bottom plate 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com