Display panel, manufacturing method thereof and display device

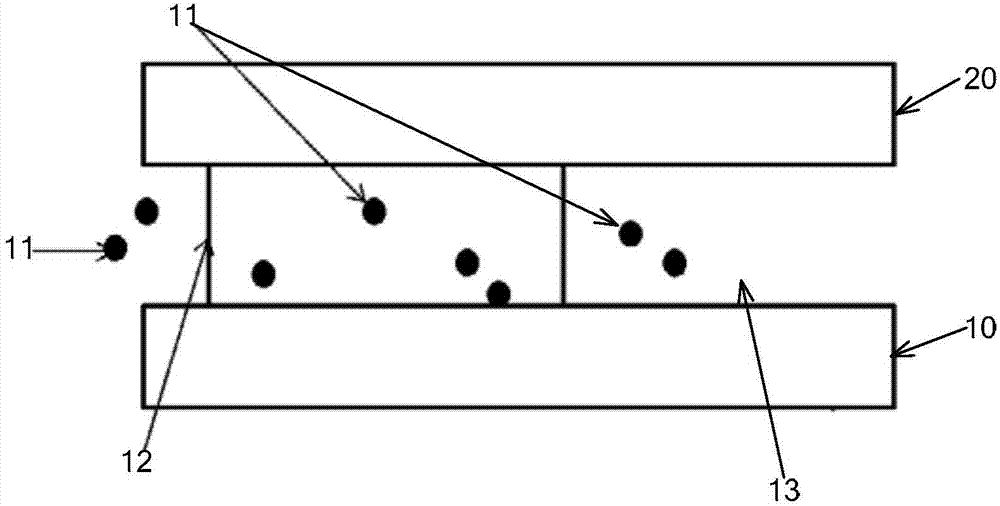

A display panel and display area technology, which is applied to static indicators, instruments, nonlinear optics, etc., can solve the problems of long development cycle and difficult realization of sealing materials, and achieve the effect of improving peripheral defects and preventing display abnormalities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

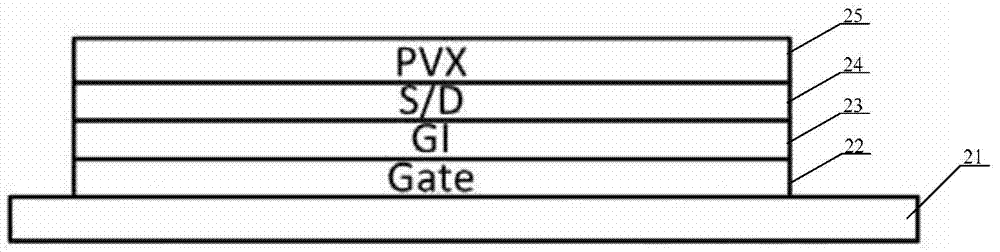

[0045] Most of the sealing glue coating areas around the existing display products are control switches. The specific structure is as follows: figure 2 As shown, it includes: a substrate 21 , a gate metal (Gate) layer 22 , a gate insulating layer (GI) 23 , a source-drain metal (S / D) layer 24 and a passivation layer (PVX) 25 located on the substrate 21 in sequence. Wherein, the gate metal layer 22 and the source-drain metal layer 24 are connected and conducted through a gate insulating layer via hole (GI via hole), serving as a control switch of the peripheral circuit.

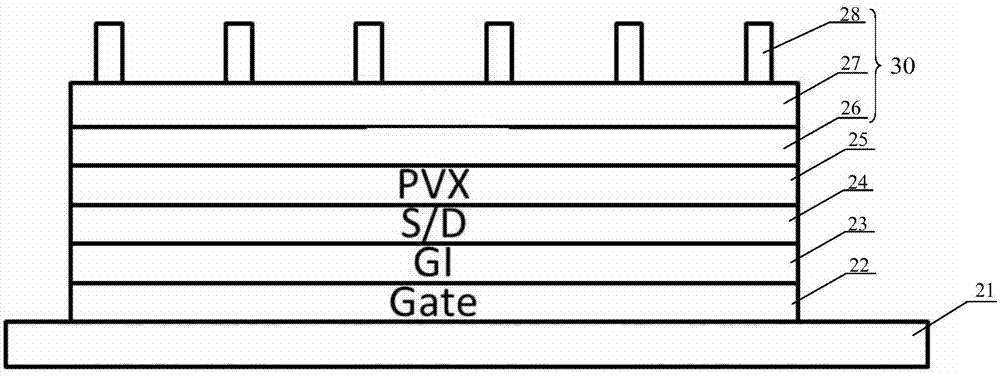

[0046] An embodiment of the present invention provides a display panel. The peripheral area of the display panel is provided with: a dust-proof structure 30; the dust-proof structure 30 is located outside the display area on the display panel and inside the outer edge of the sealant coating area; refer to image 3 As shown, the dustproof structure 30 includes: a first electrode 26, a second electrode 28, and...

Embodiment 2

[0063] On the other hand, an embodiment of the present invention also provides a method for manufacturing a display panel, including: a color filter substrate manufacturing process, an array substrate manufacturing process, and a color filter substrate and array substrate box-to-box manufacturing process, such as Figure 7 As shown, the array substrate manufacturing process includes:

[0064] 101. Forming a gate metal layer, a gate insulating layer, a source-drain metal layer, and a passivation layer sequentially on the substrate;

[0065] 102. On the substrate on which the gate metal layer, gate insulating layer, source-drain metal layer, and passivation layer are formed, form a first transparent conductive film, and form a pixel electrode or a common electrode in a predetermined display area through a patterning process, in the A first electrode is formed between the outside of the preset display area and the inside of the outer edge of the preset sealant application area; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com