Method for controlling pumping unit motor in frequency-conversion mode

A frequency conversion control, electromechanical technology, applied in the field of frequency conversion control, can solve the problems of voltage waveform distortion, low operation efficiency, waste of electric energy, etc., and achieve the effect of reducing energy waste, suppressing power generation, and reducing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] In this embodiment, a pumping unit with a 37KW motor is used, and the torque of the motor of the pumping unit is detected by a torque detector installed on the shaft of the motor. The torque detector is selected as STM2000.

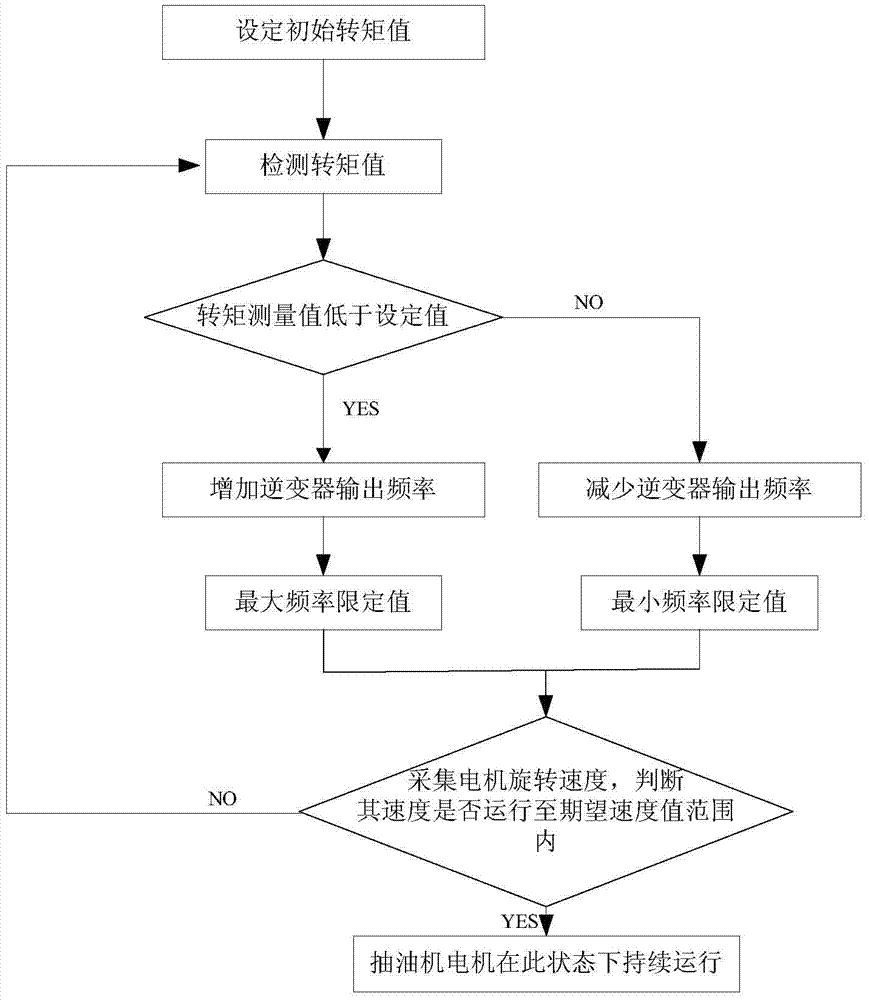

[0016] The specific process of frequency converter frequency control for the pumping unit of the present embodiment 37KW motor is as follows figure 1 Shown: Include the following steps:

[0017] Step 1: Set the initial torque value to zero, and specify the positive direction of the torque of the motor, specifically: when the detected torque value is greater than zero, the torque direction is positive; when the detected torque value is less than zero, turn to The moment direction is negative.

[0018] Step 2: Detect the torque value of the 37KW motor through the torque detector. If the detected torque value is less than the initial set torque value zero, it means that the motor is in the state of generating power. At this time, there is braking ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com