Automatic positioning glue spraying method and equipment for tires

An automatic positioning and tire technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of high cost, incapable of automatic positioning, poor effect, etc., and achieve the prevention of tire leakage, low production cost, and high production efficiency. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

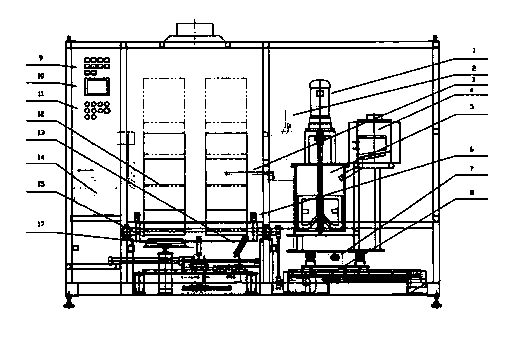

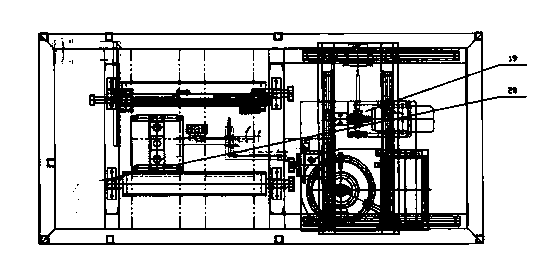

[0069] Turn on the tire automatic positioning glue spraying equipment, and select the automatic positioning system in the touch screen 10 .

[0070] The tires are placed onto the twin rollers 16 manually.

[0071] Press the start button to transmit the start signal to the PLC controller, and the PLC controller will automatically complete the following actions:

[0072] (1) The adjustable tire stop lever 17 and the spray gun 3 are reset to the origin by the synchronous motor through the ball screw, and the origin is the initial position of the adjustable tire stop lever 17 and the spray gun 3 (not shown in the figure) .

[0073] (2) Control the air cylinder by the solenoid valve to raise the adjustable tire stop lever 17 (not shown in the figure).

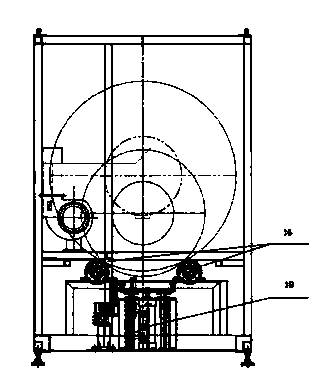

[0074] (3) The motor is controlled by a frequency converter (motor governor), the V-belt drives the double rollers 16 to rotate, and the double rollers 16 drive the tires 12 to rotate;

[0075] One side of tire 12 (opposite figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com