Steel back pressure hypotenuse fine blanking continuous die and steel back production method

A steel back and hypotenuse technology, which is applied in the field of steel back pressure bevel edge fine-blanking continuous die and steel back production, can solve the problems of poor flatness of the back of the deformation perimeter, large degree of plastic deformation of the material, and one-sided force of the mold. , to achieve the effect of ensuring blanking clearance and guiding accuracy, improving production efficiency and saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

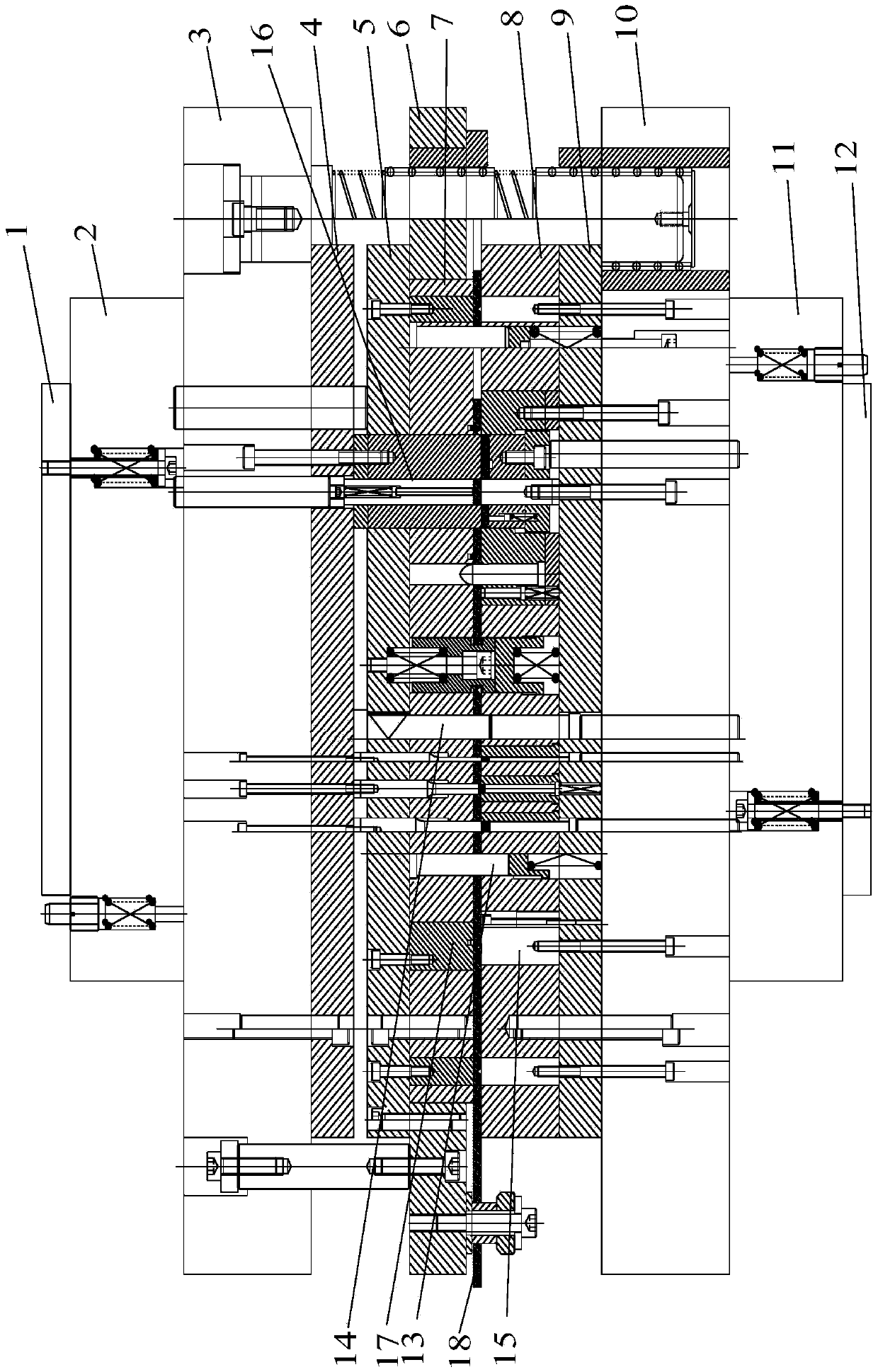

[0038] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

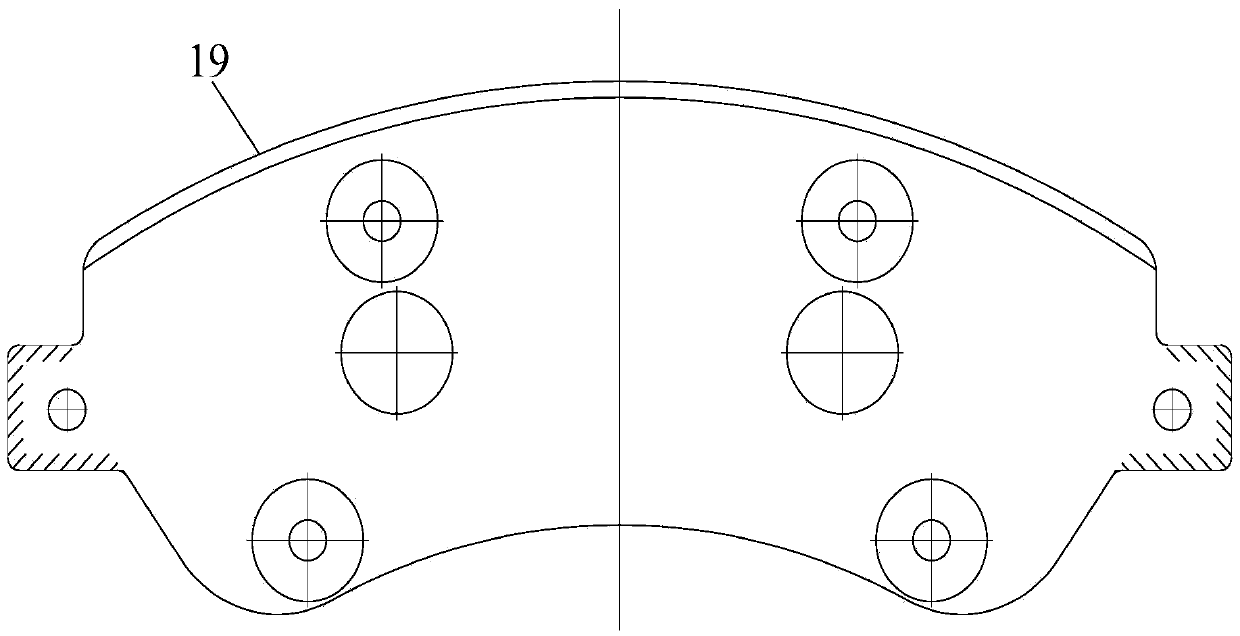

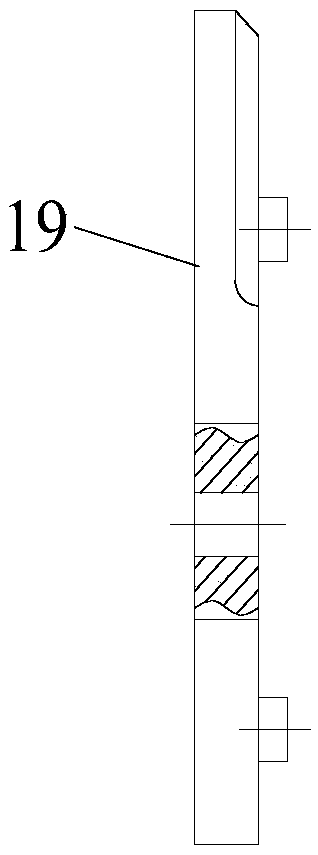

[0039] Such as Figure 1 to Figure 5 As shown, the embodiment steel back pressure hypotenuse fine-blanking continuous die includes from top to bottom an upper bridge plate 1, an upper insert ring 2 arranged under the upper bridge plate 1, and an upper insert ring arranged under the upper insert ring 2. Die base 3, upper backing plate 4 arranged under the upper die base 3, ring gear plate backing plate 5 under the upper backing plate 4, middle support plate 6 under the ring gear backing plate 5, The ring gear plate 7 embedded in the middle support plate 6, the lower template 8 arranged under the middle support plate 6, the lower backing plate 9 arranged under the lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com