Automatic welding method

An automatic welding and welding torch technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve a large number of problems such as slag spraying, achieve the effects of reducing heat energy consumption, improving industrial automation welding, and preventing deformation defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the above-mentioned and other objects, features and advantages of the present invention more obvious and easy to understand, the preferred embodiments of the present invention are exemplified below, and are described in detail as follows in conjunction with the accompanying drawings:

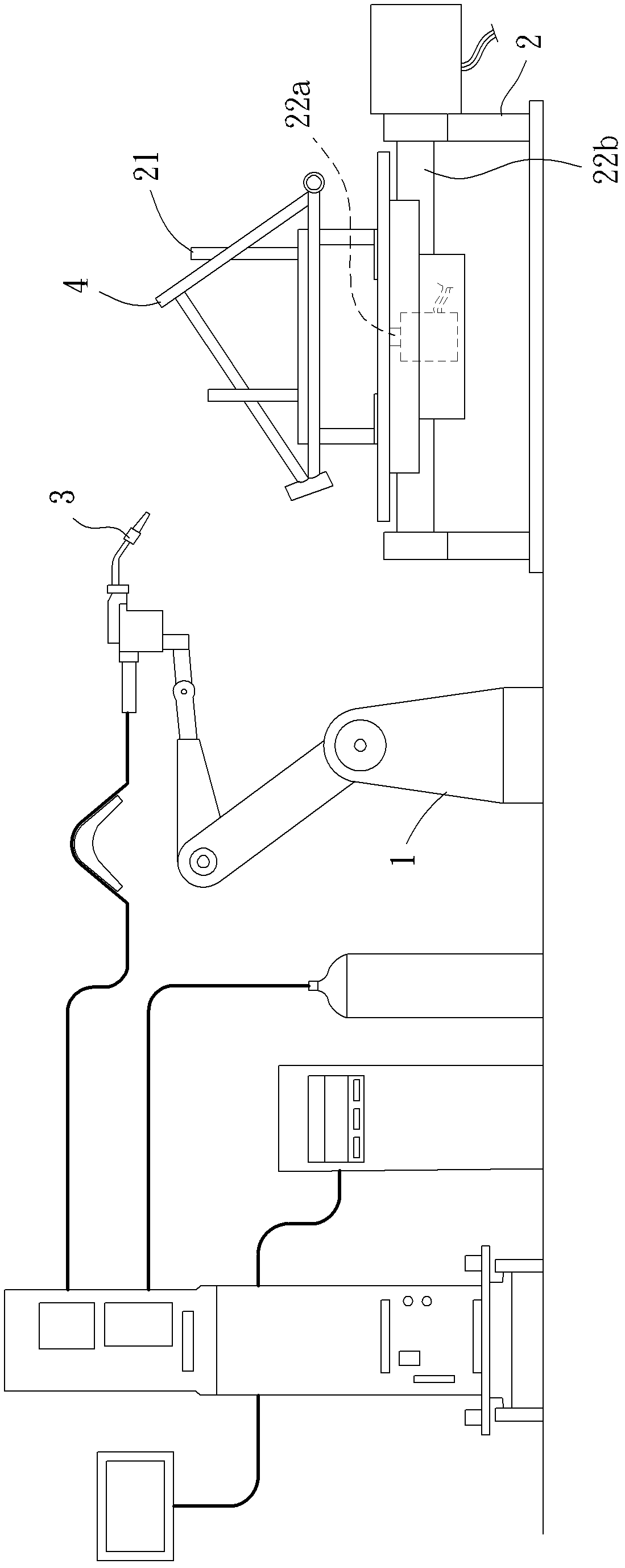

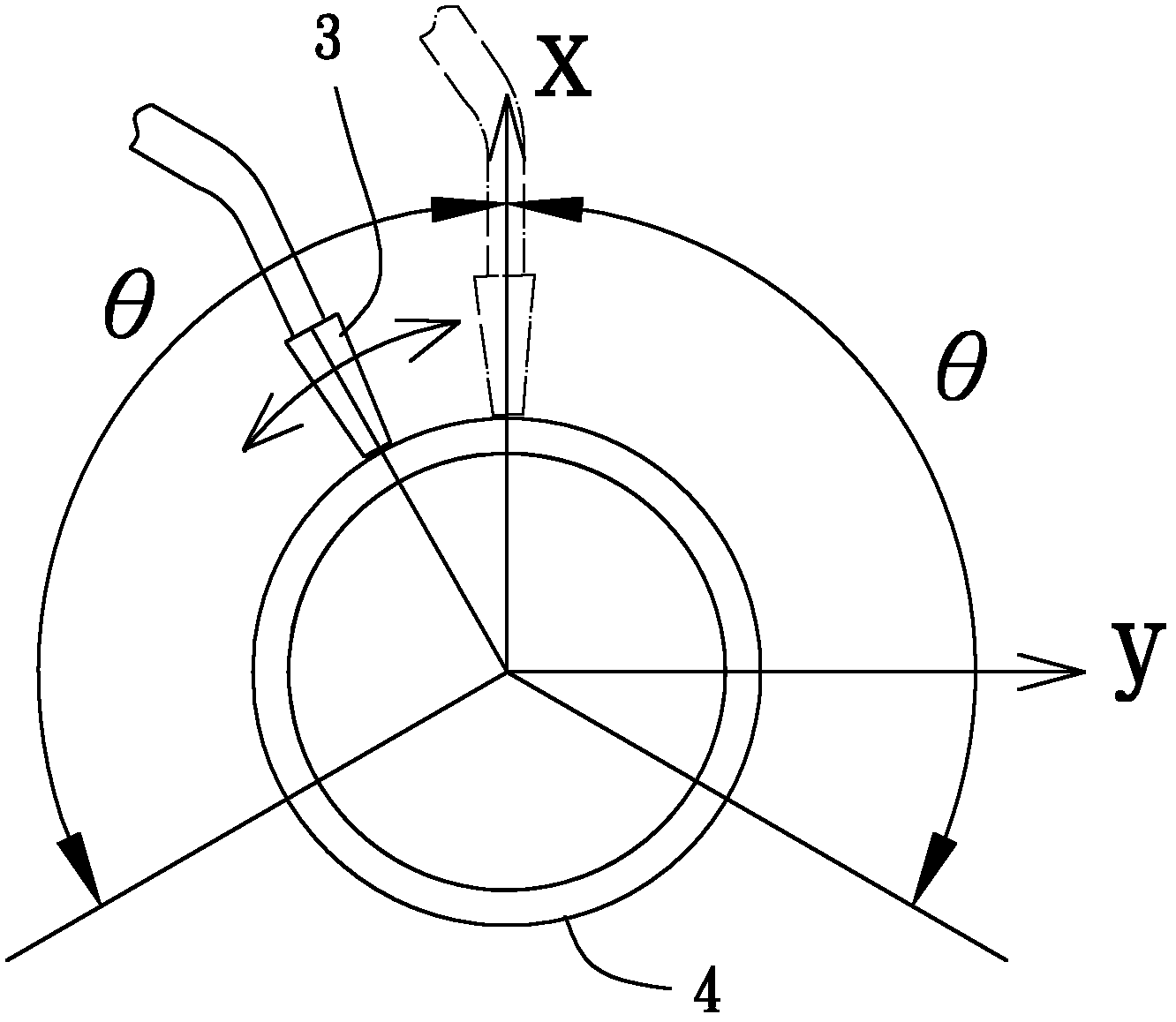

[0038] Please refer to figure 1 As shown, it is an automatic welding machine, the automatic welding machine includes a welding torch clamping device 1 and a carrier 2, the welding torch clamping device 1 is used to clamp a welding torch 3, and the welding torch clamping device 1 It can be selected as an adjustable manipulator or a fixed manipulator, but not limited to this; the surface of the carrier 2 is provided with a clamp 21, and the clamp 21 is used to fix a metal object 4 to be welded, So that the welding gun 3 can weld the metal object 4 by the way of short-circuit arc moving. In addition, the carrier 2 can optionally be provided with two rotating shafts 22a, 22b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fatigue bending times | aaaaa | aaaaa |

| fatigue bending times | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com