Method for installing externally connected hose of toilet bowl and combined spanner special for externally connected hose

An installation method and toilet technology, applied in the direction of wrenches, manufacturing tools, wrenches, etc., can solve problems such as leakage, and achieve the effect of easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

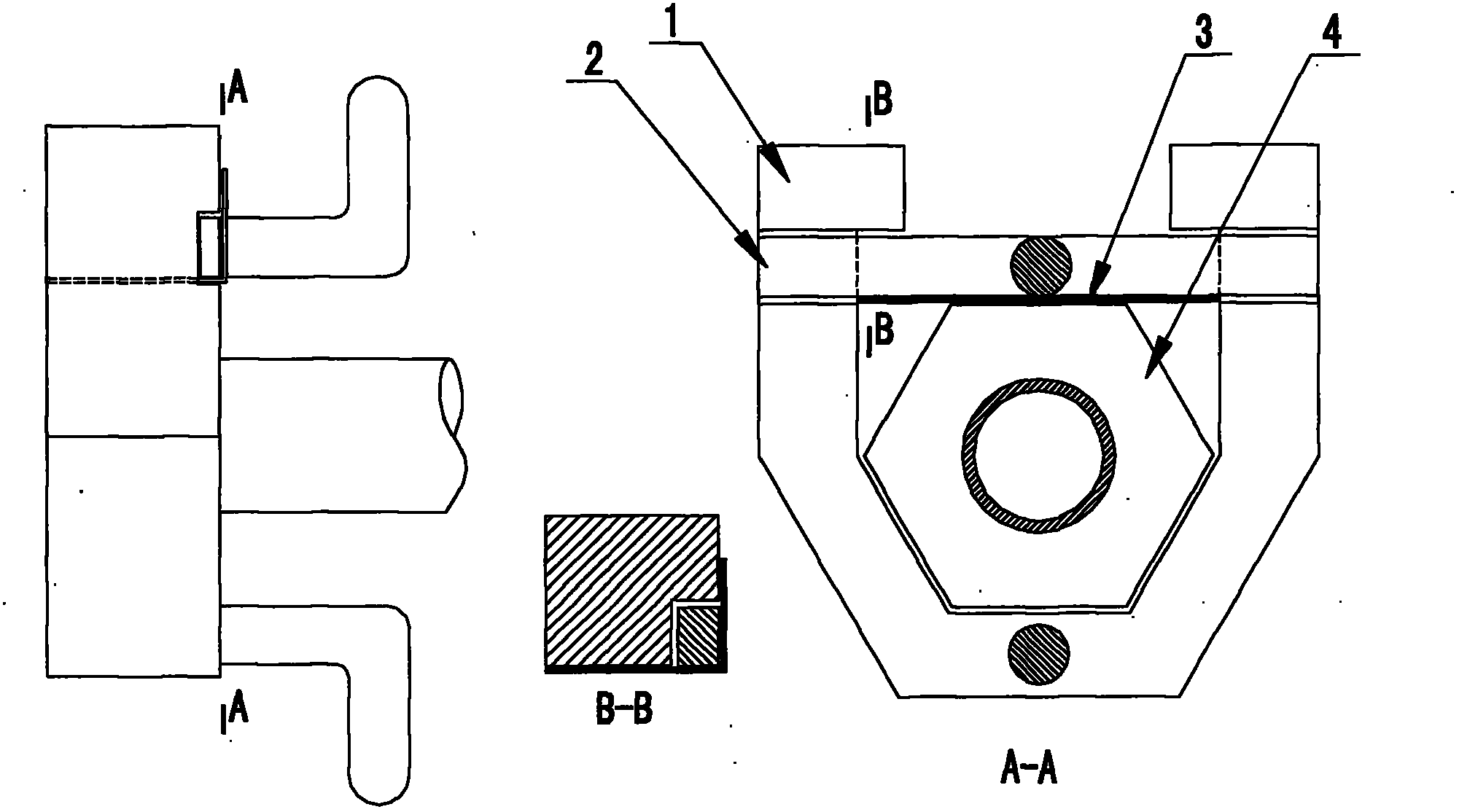

[0012] figure 1 The special combined wrench for the external hose of the toilet shown is composed of a wrench body, a compression block, and a compression gasket. The compression gasket is one or more pieces of metal sheets or thin wood chips or thin hard paper sheets. There are two rectangular grooves in a straight line on the hand body, and there is an outward hook on the wrench body, and there is also a hook on the pressing block that is symmetrical to the hook on the wrench body. In the rectangular groove on the hand body, this part is as figure 1 As shown, part 1 wherein is a wrench body, 2 is a compression block, 3 is a compression gasket, and 4 is a union nut on the external hose of the toilet.

Embodiment 2

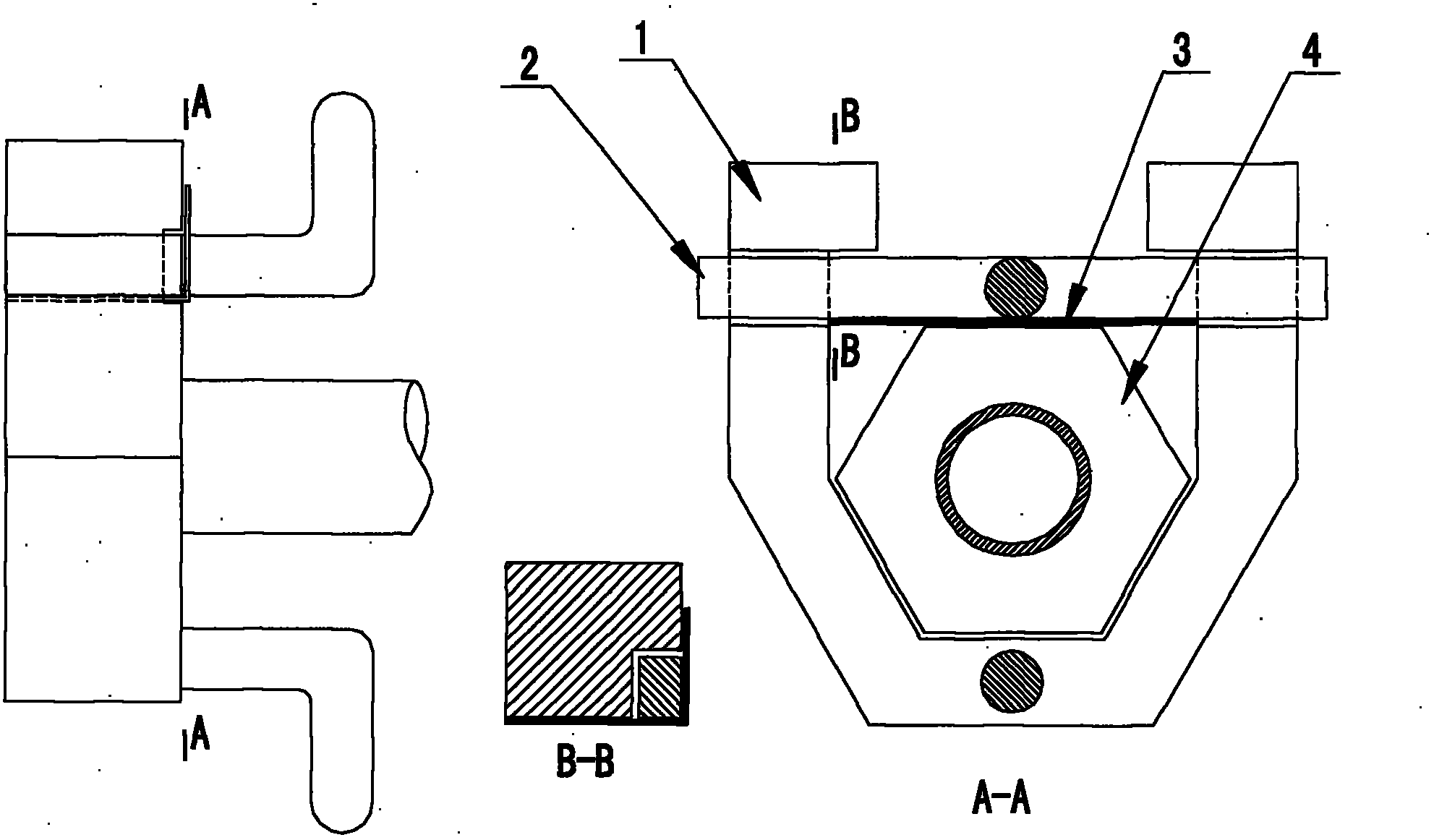

[0014] figure 2 The special combined wrench for the external hose of the toilet shown is composed of a wrench body, a compression block, and a compression gasket. This part is as follows: figure 2 As shown, part 1 wherein is a wrench body, 2 is a compression block, 3 is a compression gasket, and 4 is a union nut on the external hose of the toilet. It is characterized in that: there is a pair of claws on the pressing block, and the claws can hold the wrench body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com