Patents

Literature

42results about How to "Ensure no leaks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

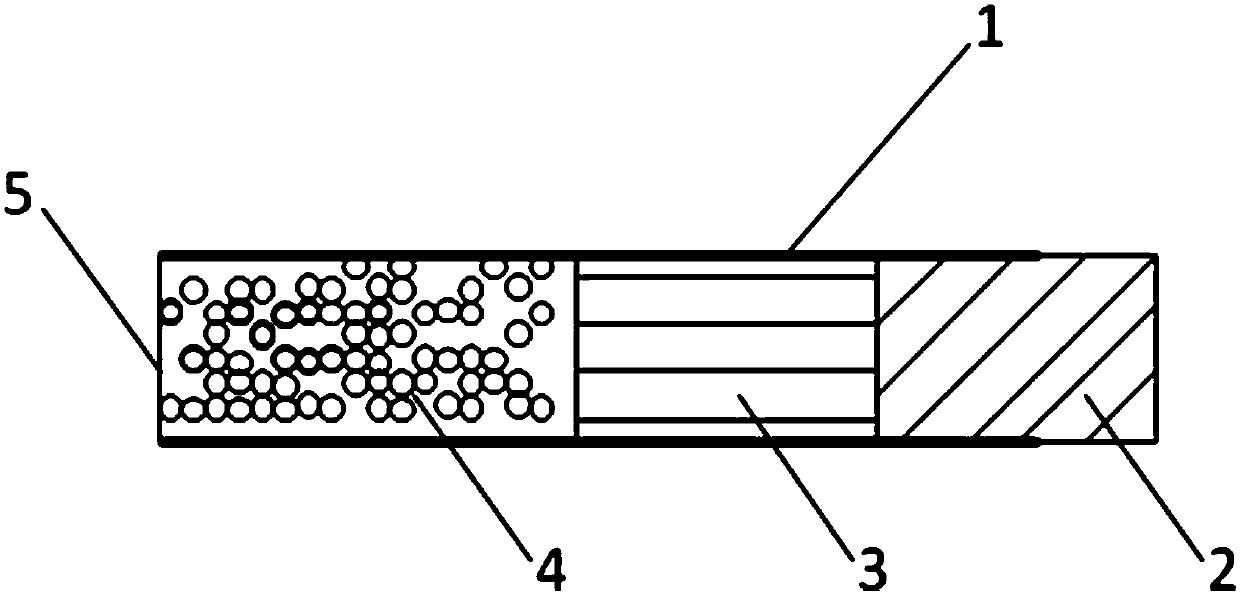

Non-rolled novel tobacco product containing tobacco particle material

PendingCN109512031AAvoid direct contactImprove comfortTobacco devicesGlass/slag layered productsEngineeringTobacco product

The invention discloses a non-rolled novel tobacco product containing a tobacco particle material. The product is composed of a cigarette holder segment, a cooling segment and a tobacco particle segment which are sequentially wrapped with a paper hollow tube from a front end to a tail end; a tail end port of the paper empty tube is plugged by a breathable sheet material; the cigarette holder segment and the cooling segment are provided with axial running-through ventilation holes, and the tobacco particle segment is filled with the tobacco particle material. The non-rolled novel tobacco product has the following advantages that the special cigarette holder segment structure is adopted, during use, the paper empty tube can be externally caught, the direct contact with the hard outer wall ofthe paper empty tube is avoided, and the comfort is better; the tobacco particle material is adopted as a smoke releasing material, and the taste is better; a specially-made breathable nano-materialcapable of preventing liquid permeation is adopted as the breathable sheet material, not only can the normal use of heated tobacco be ensured, but also it can be ensured that tobacco liquid does not leak, and the product is safe and reliable.

Owner:CHINA TOBACCO ANHUI IND CO LTD

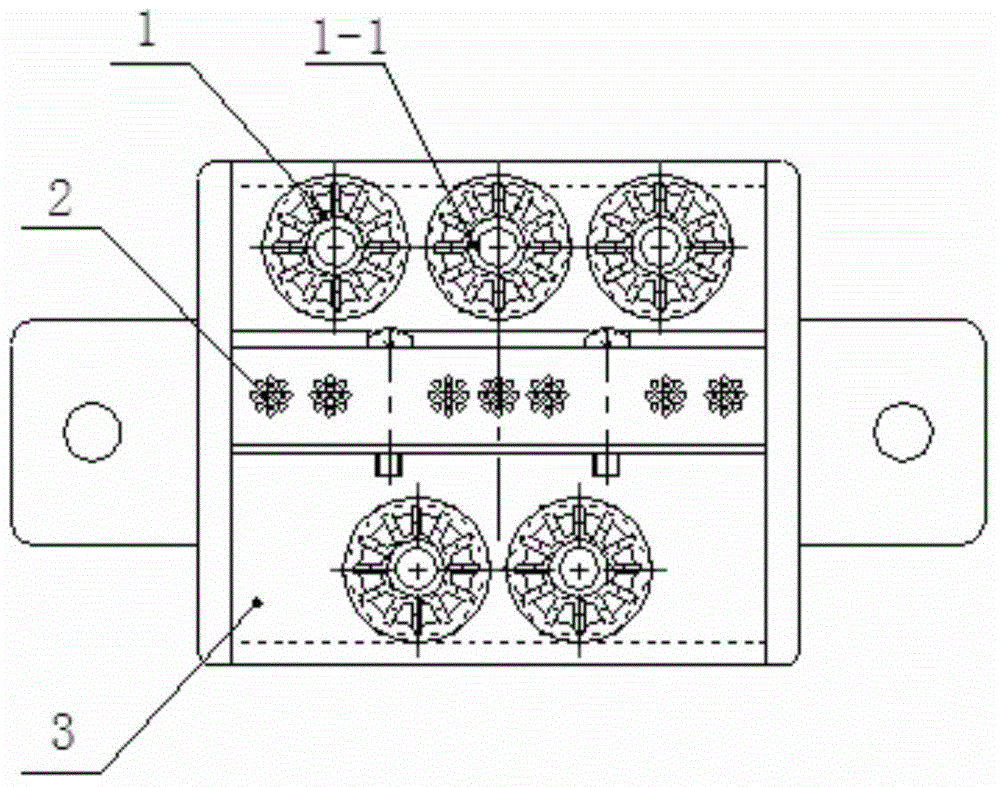

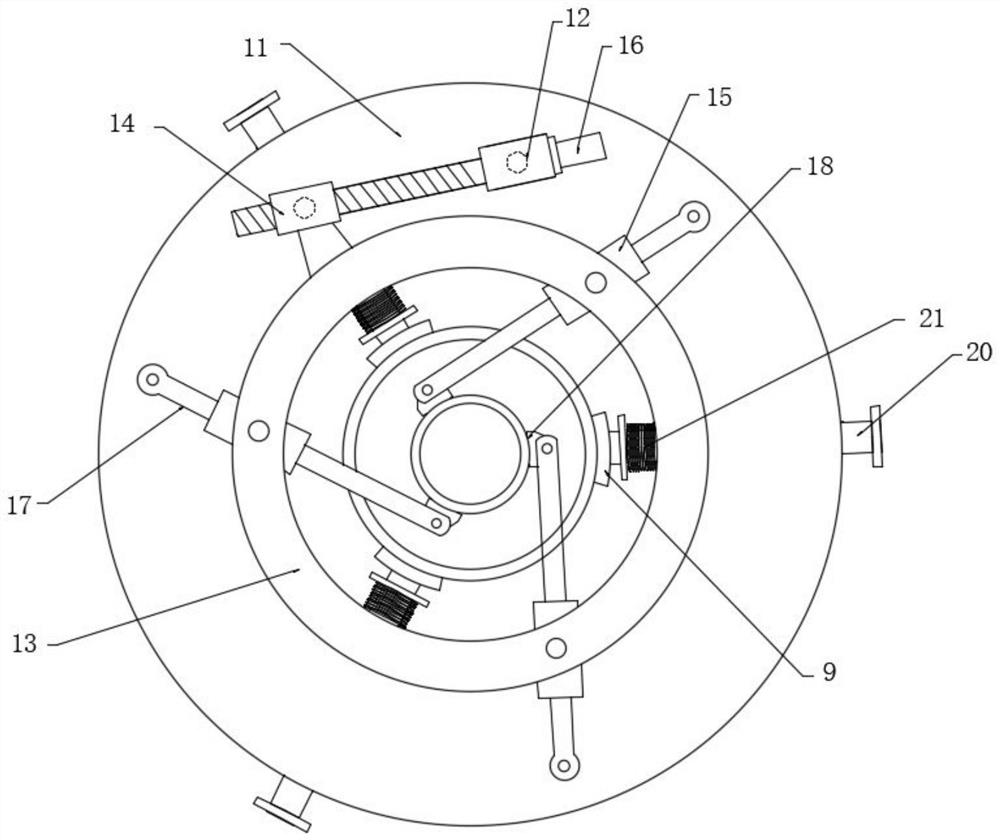

Double-surface laminating material bag opening mechanism with hot cutting lifting handle

The invention discloses a double-surface laminating material bag opening mechanism with a hot cutting lifting handle. The double-surface laminating material bag opening mechanism with the hot cutting lifting handle comprises opposite vacuum shells positioned on a left side and a right side, wherein the rear end of each vacuum shell is communicated with a vacuum pipeline; the front end of each vacuum shell is connected with sucking discs which are aligned; the sucking discs are installed on the vacuum shell by joints; the center of each sucking disc is provided with supporting hairbrushes which are aligned; the left sucking disc and the right sucking disc are cooperatively clamped on the lifting handle position of a woven bag. According to the double-surface laminating material bag opening mechanism with the hot cutting lifting handle, which is disclosed by the invention, the upper position and the lower position of each sucking disc, where the lifting handle of a plastic bag is sucked, are subjected to bag opening, and the broken positions of the lifting handles are effectively supported by the hairbrushes to prevent materials from leaking.

Owner:ANHUI YONGCHENG ELECTRONICS & MECHANICAL TECH

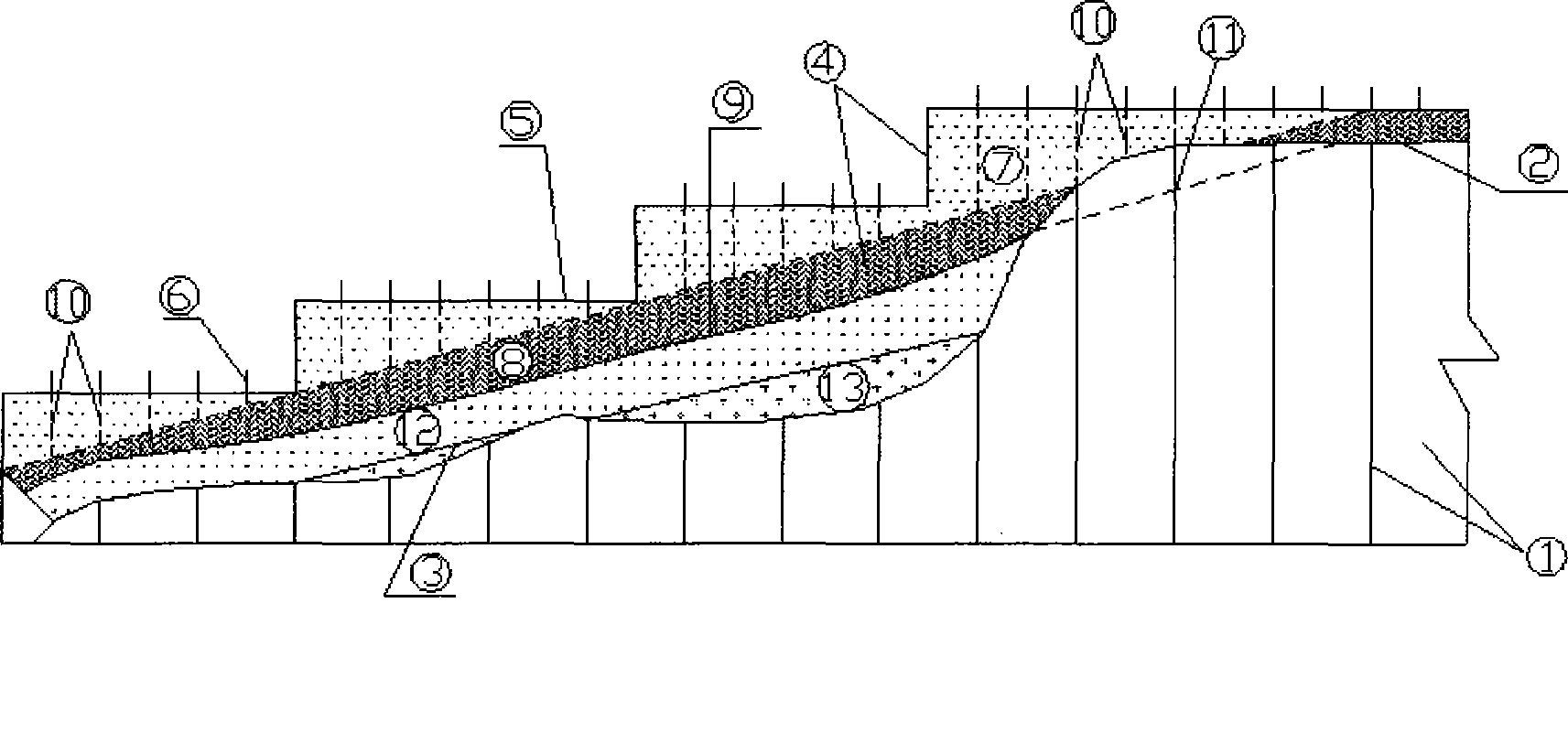

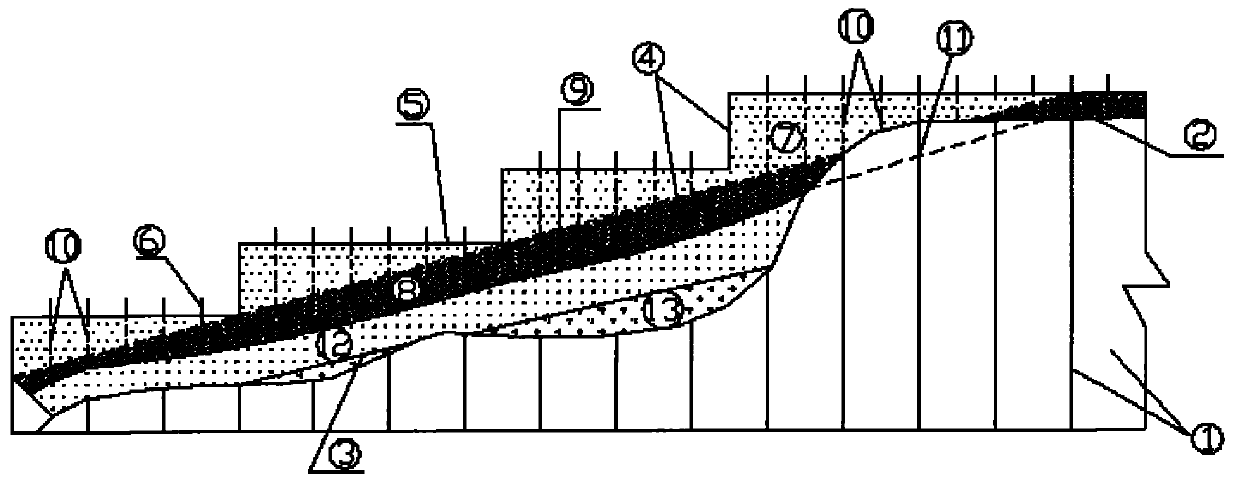

Method for manufacturing conducting solution simulation test model for studying three-dimensional seepage field of dam

The invention relates to a method for manufacturing a conducting solution simulation test model for studying a three-dimensional seepage field of a dam, which is characterized in that the conducting solution simulation test model integrates the terrain, the dam structure, the measuring point and other arrangements into a whole and can meet the test requirement without rotating and cutting a prototype. The conducting solution simulation test model is used for point testing and three-dimensional seepage surface arranging and overcomes the defects that a traditional model needs to penetrate through an internal structure to collect information on the elevation and the potential of the seepage surface; a seepage preventing ring made of strip-shaped watertight soft material ensures that the conducting solution of the conducting solution simulation test model can not seep and an electric field of the conducting solution simulation test model is undistorted; and the conducting solution simulation test model is made of conventional material, is strongly intuitive in appearance and is convenient for test, measurement and repair.

Owner:HOHAI UNIV

Processing technology for crackle celadon cosmetic bottle having non-crackle glaze inner surface

ActiveCN110228993AImprove display effectConvenient for domesticCeramic materials productionClaywaresSlurryBottle

The invention discloses a processing technology for a crackle celadon cosmetic bottle having a non-crackle glaze inner surface. The processing technology comprises the following steps: a) preparing ablank material, b) preparing slurry, c) forming a green body, d) performing biscuiting on the green body, e) preparing inner glaze slurry, preparing outer glaze slurry, and the like. Compared with theprior art, the processing technology provided by the invention applies Longquan celadon to the field of cosmetics, and can ensure that the cosmetic bottle does not leak a liquid cosmetic when used for storing the liquid cosmetic and obtain an exquisite unique and elegant glaze appearance effect, thereby improving displayability of the cosmetic bottle and facilitates domestic and international market promotion of the cosmetics; and the processing technology thoroughly overcomes the defect that a current crackle glaze easily cracks a green body through pulling, and achieves a combination of biscuit, an inner glaze and an outer glaze; the inner glaze has no cracks, so that when the cosmetics are stored for a long time, the cosmetics can be prevented from entering the green body; and at the same time, the outer wall has a decorative effect of a celadon crackle glaze, so that the cosmetic bottle has local characteristics in Lishui Province and even Chinese characteristics after being usedto hold the cosmetics, and greatly improves the grade of the products.

Owner:龙泉市青瑜瓷坊

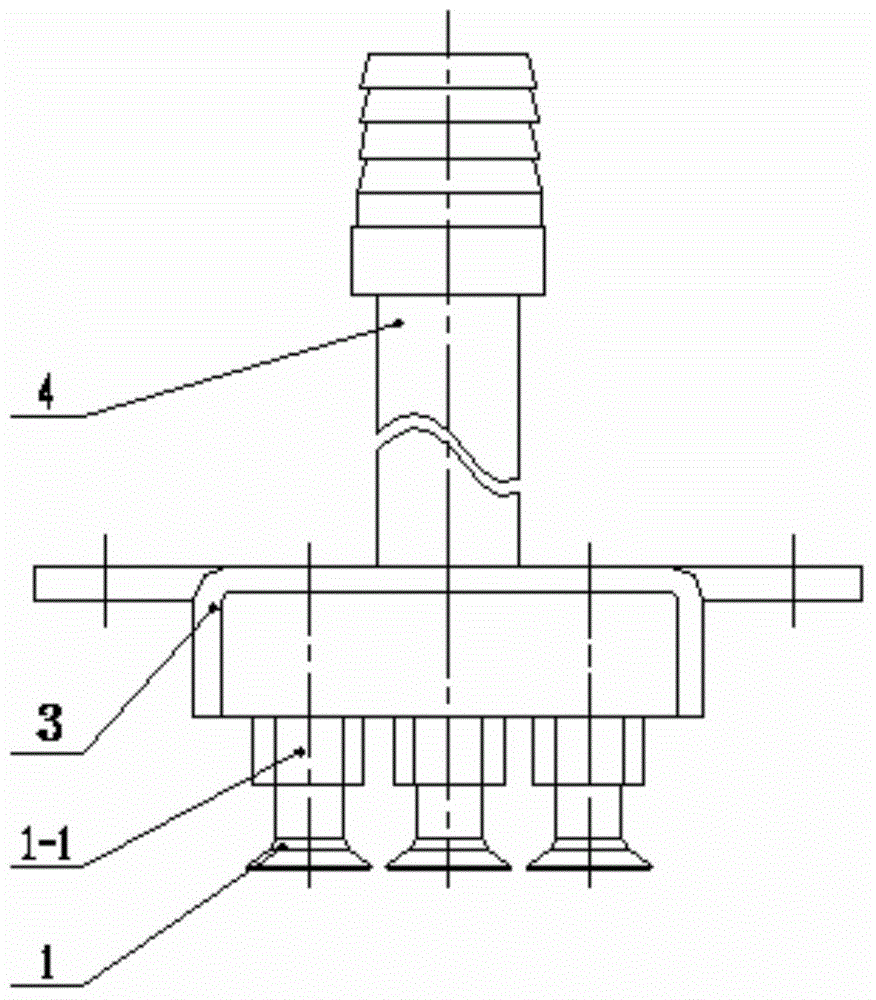

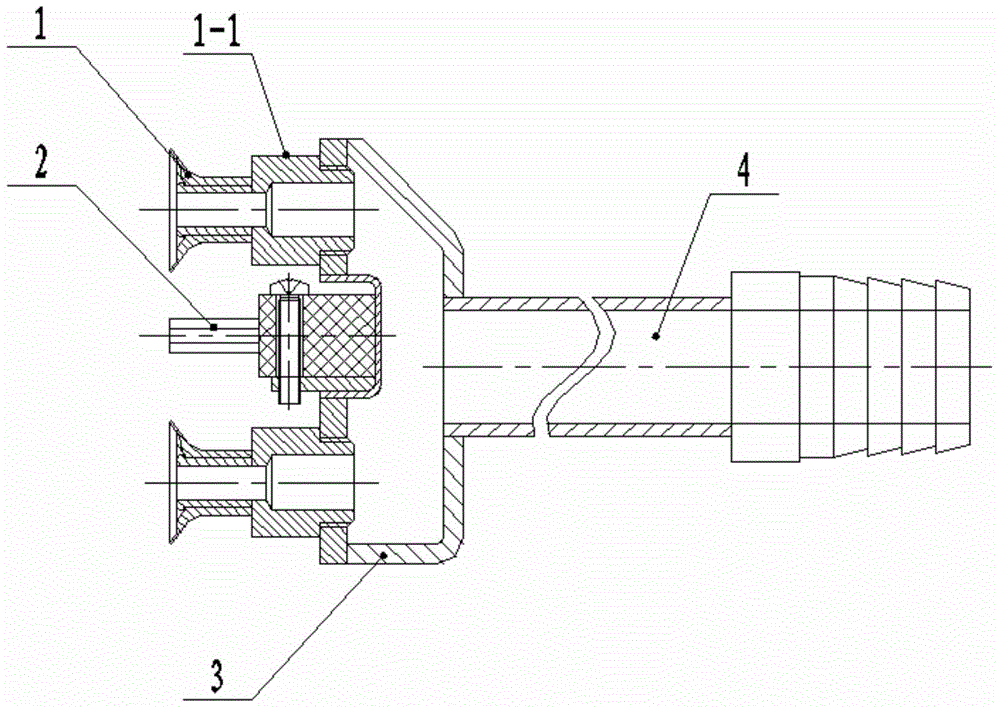

Pipe fitting processing technology

The invention discloses a pipe fitting processing technology for manufacturing tee-fittings on aviation unmanned aerial vehicles. The technology comprises the steps of: a) performing, b) annealing treatment, c) cold extrusion, d) reshaping, and e) surface shot blasting treatment. The technology provided by the invention adopts advanced hot press forging and cold extrusion processing, the dimensional precision is high, the surface roughness is small, the internal metal fluidity is good, reasonable fiber flow linear distribution can be formed, and the tensile strength, wear resistance and mechanical properties are greatly enhanced. The manufactured seamless tee-fittings can effectively prevent air leakage and liquid leakage phenomena, have high safety coefficients and good use effect, can ensure no leakage of the hydraulic circuit. The tolerance and surface roughness can both reach the aviation industry standards, and 40% of the raw materials can be saved, the production cost is effectively reduced, the tee-fittings can be supportingly applied to China's unmanned aircrafts, and have advanced technology and market prospects.

Owner:JIAXING MASTER PLUMBING

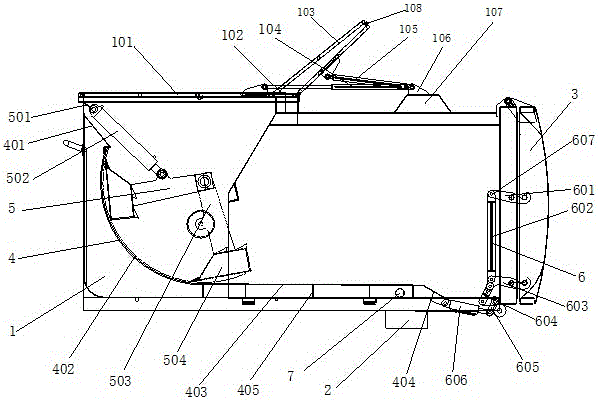

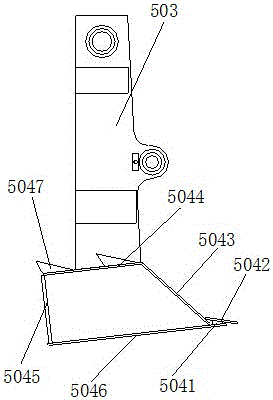

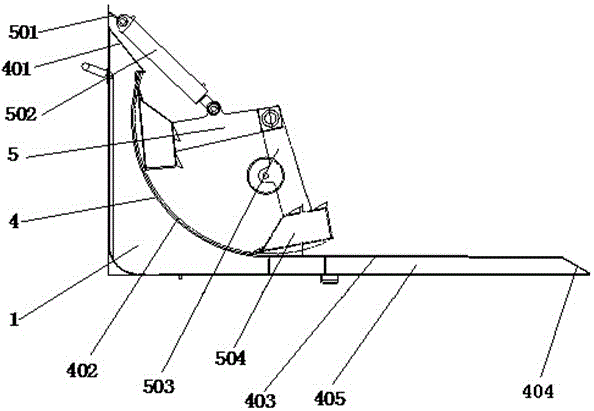

Swing arm type compression garbage can and method for garbage extrusion performed by means of swing arm type compression garbage can

ActiveCN105035608ANo pollution in the processNice appearanceRefuse vehiclesLocking mechanismCompression device

The invention relates to the technical field of garbage recycling and provides a swing arm type compression garbage can and a method for garbage extrusion performed by means of the swing arm type compression garbage can. The swing arm type compression garbage can comprises a compression can body, a sewage tank and a rear opening door. The sewage tank is arranged at the bottom of the compression can body and connected with a sewage drainage connector inside the compression can body. The rear opening door is connected with the tail of the compression can body. The compression can body is internally provided with a sliding plate, a pendulum type compression head and a locking mechanism. The sliding plate is arranged at the bottom of the compression can body. The pendulum type compression head moves along the sliding plate. The pendulum type compression head comprises a rotating rod, a compression oil cylinder, a swing arm and a compression push plate. One end of the rotating rod is installed at the vertex angle of the compression can body, and the other end of the rotating rod is connected with the top end of the compression oil cylinder. The bottom end of the compression oil cylinder is connected with a swing arm. The compression push plate is installed at the bottom end of the swing arm. The swing arm type compression garbage can is provided with the garbage pushing and compression devices, meanwhile the pushing speed and the compression speed are high on the basis of the pendulum type principle, solid-liquid separation is achieved, the loading efficiency is high, and manpower is saved.

Owner:上海赫得环境科技股份有限公司

Form erecting method for casting dome roof in situ

ActiveCN102644373AReduce lossGuarantee molding qualityForms/shuttering/falseworksBuilding material handlingQuality assuranceMaterial consumption

The invention discloses a form erecting method for casting a dome roof in situ. The form erecting method comprises the following steps: matching templates and indwelling a construction seam; carrying out in-situ fabrication and subsection assembling on inner and outer templates by means of amplifying a sample, wherein the arc length of the dome roof is determined by the height of each section according to specification of a gluing board, and a construction indwelling position of a concrete horizontal seam is as the same as the height of the semispherical outer template of the dome roof; connecting the outer template and the inner template through a split bolt; in a process of pouring concrete each section, preventing from indwelling the construction seam on a wood beam with a certain specification; manufacturing a sub-template back edge; and configuring an arc-shaped panel and mounting the templates. According to the form erecting method provided by the invention, the inner and outer templates are prefabricated in situ and assembled in a subsection manner by means of amplifying the sample. The inner template is assembled and mounted on the dome roof for one time, and the outer template and concrete are constructed in a subsection manner; and the templates are used for turnover manner. The form erecting method provided by the invention has the characteristics of low material consumption, turnover use, simplicity in assembling, rapid construction speed, easiness for quality assurance, low construction cost and high security.

Owner:青建集团股份公司

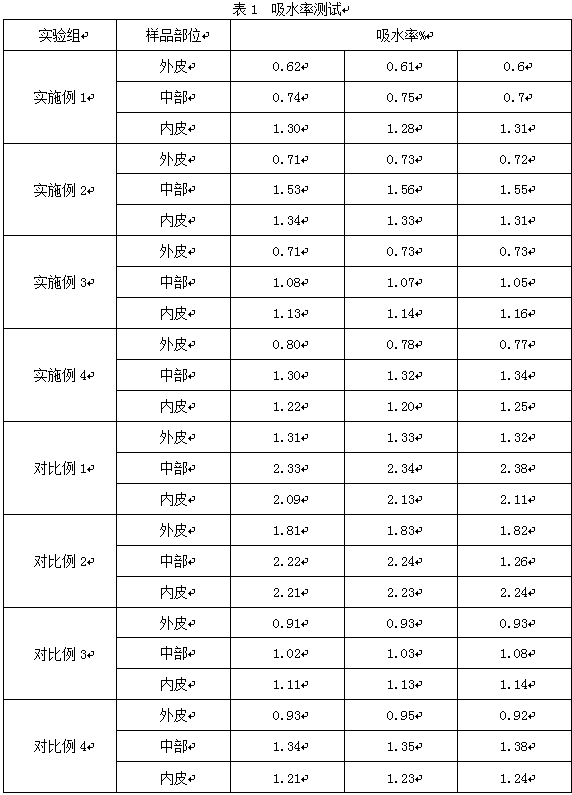

Formula and production process for ceramic storage tank

The invention provides a formula for a ceramic storage tank. The ceramic storage tank is prepared from the following raw materials by weight: 60-80 parts of Huguan green gangue, 15-25 parts of sandstone clinker, 10-20 parts of quartz, 25-40 parts of feldspar and 5-15 parts of kaolin. The ceramic storage tank of the invention solves the problem of leakage and can be used in the liquor, vinegar andchemical industries; the production of large-capacity storage tanks and fermentation tanks is realized; and the water absorption rate of the outer surface of the ceramic storage tank of the inventionis less than 1%, which ensures that the ceramic storage tank does not leak, and the inner surface and the middle portion of the ceramic storage tank have large water absorption rates, which is beneficial for the propagation of beneficial microorganisms, and thus, the ceramic storage tank can be used as a fermentation tank.

Owner:山西太行陶瓷有限公司

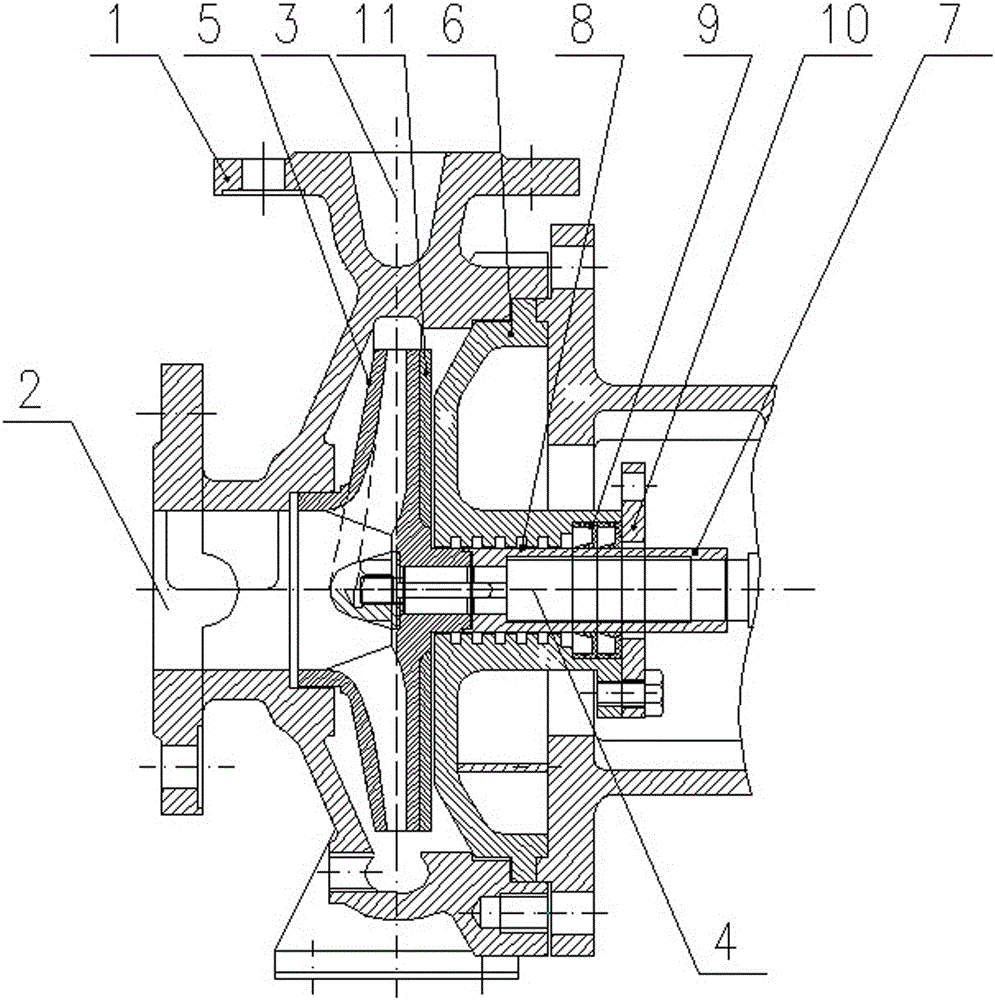

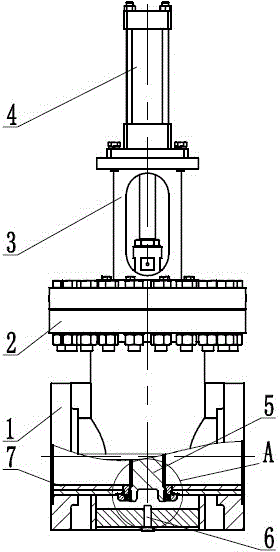

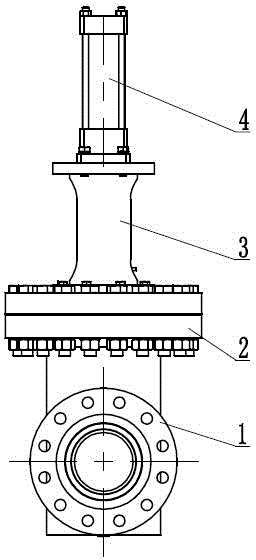

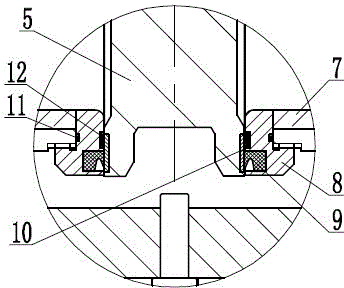

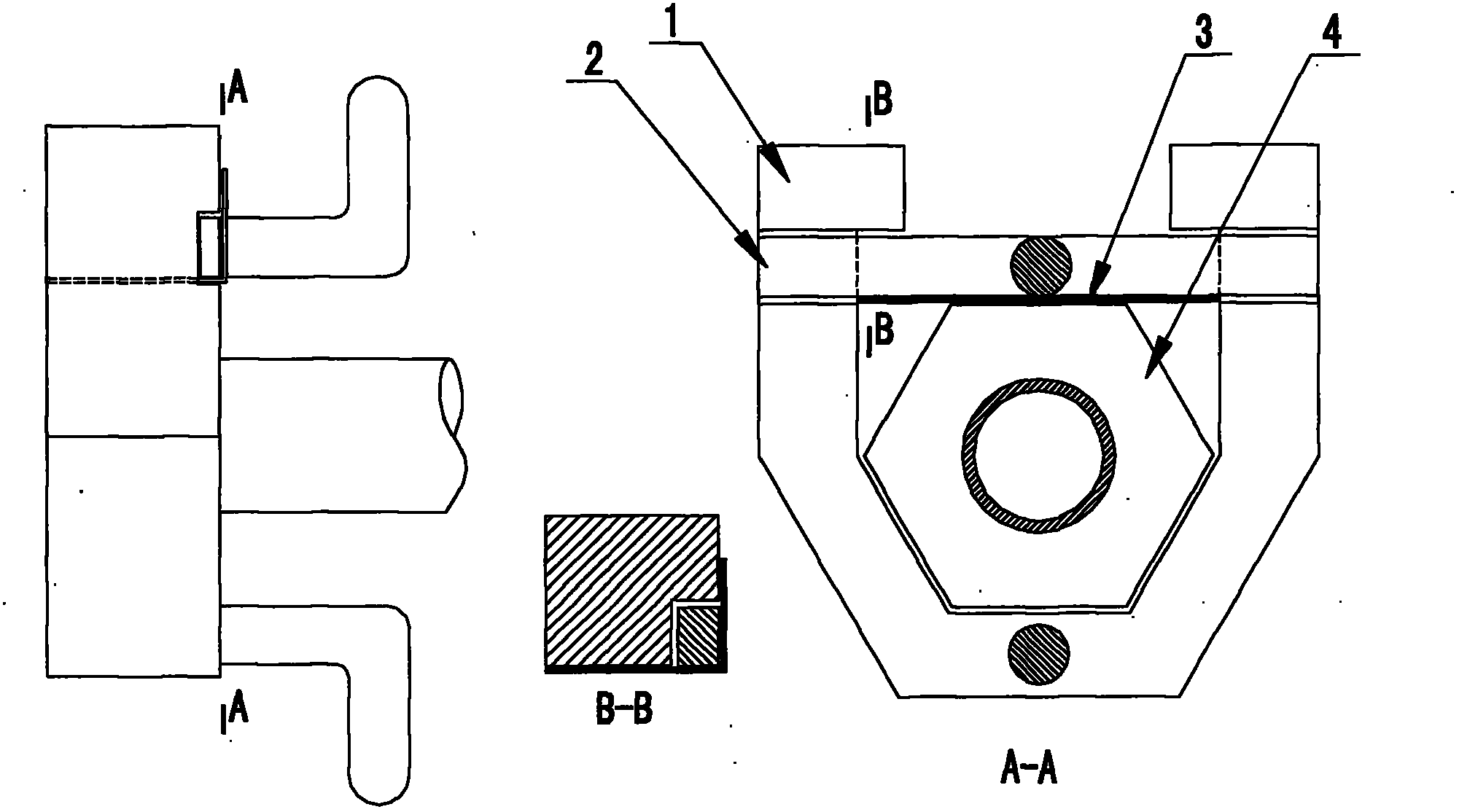

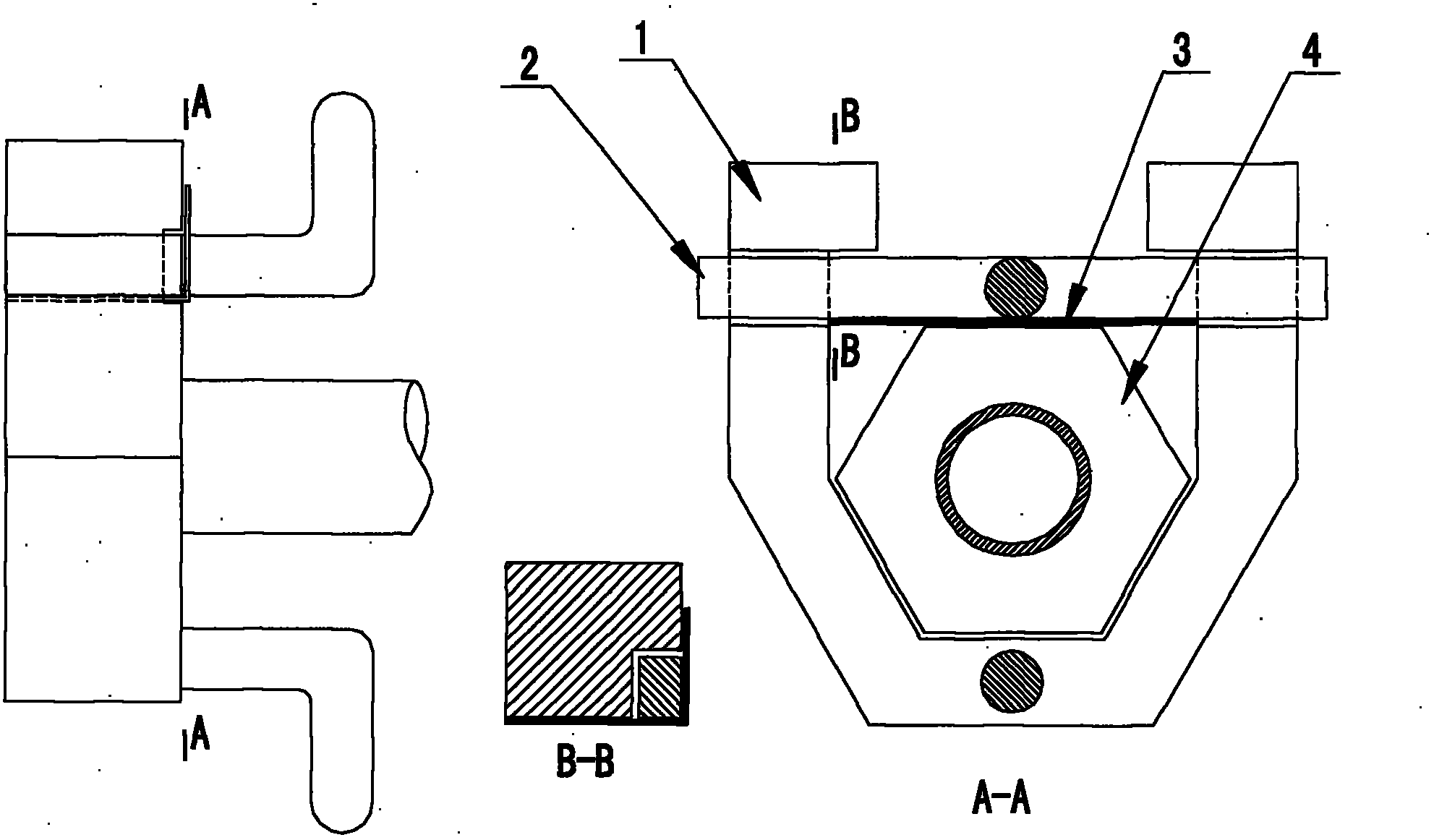

Leak-free centrifugal pump

PendingCN106609759AEnsure no leaksGuaranteed stable operationPump componentsRadial flow pumpsCentrifugal pumpLabyrinth seal

The invention relates to a leak-free centrifugal pump. The leak-free centrifugal pump comprises a pump casing, wherein a water outlet and a water inlet are formed in the pump casing; a rotating shaft is arranged in the pump casing; a working impeller is arranged at the end part of an extending end of the rotating shaft; a pump cover is arranged on the end face of one side of the pump casing; the rotating shaft penetrates through and is connected with the pump cover; a shaft sleeve sleeves the rotating shaft; a labyrinth seal and an oil seal are sequentially arranged between the shaft sleeve and the inner hole wall of the end cover from inside to outside; an oil seal gland is arranged on the outer end face of the pump cover and extrudes the oil seal; and a sealing impeller is arranged between the working impeller and the pump cover and is fixedly arranged on the rotating shaft.

Owner:JIANGSU JIANGDA PUMP IND MFR

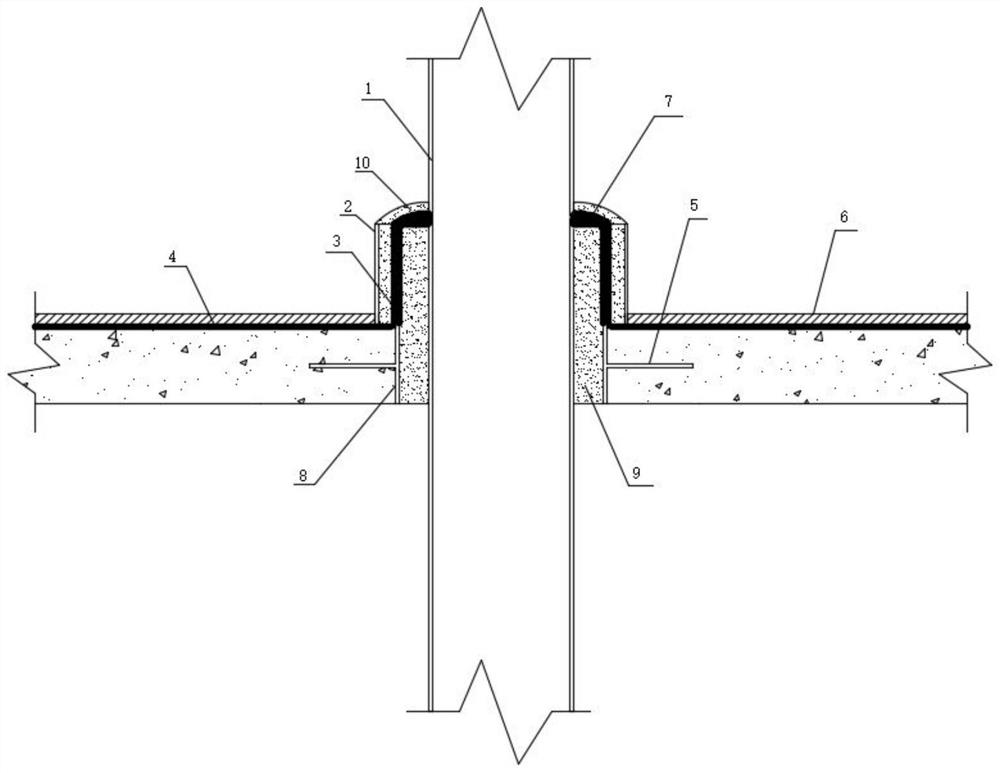

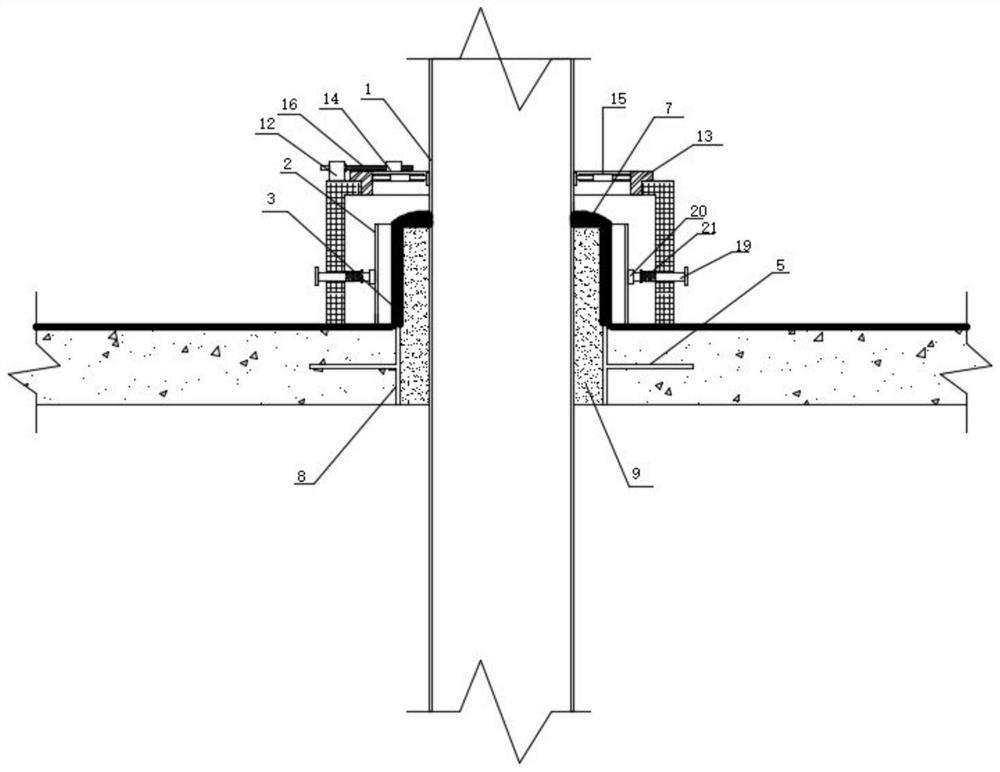

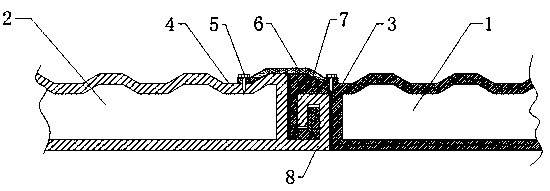

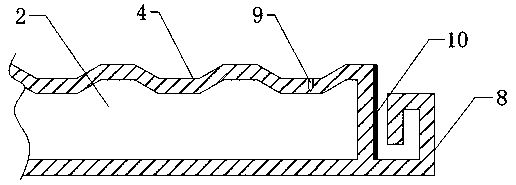

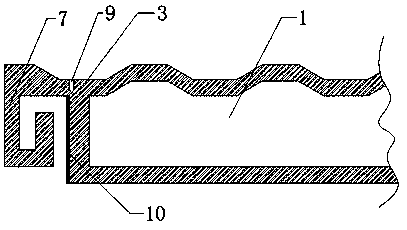

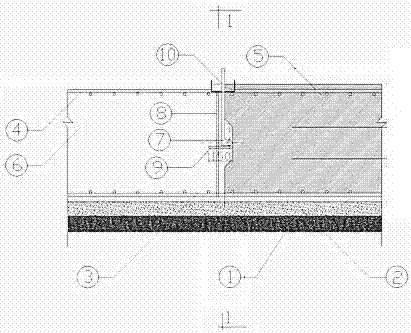

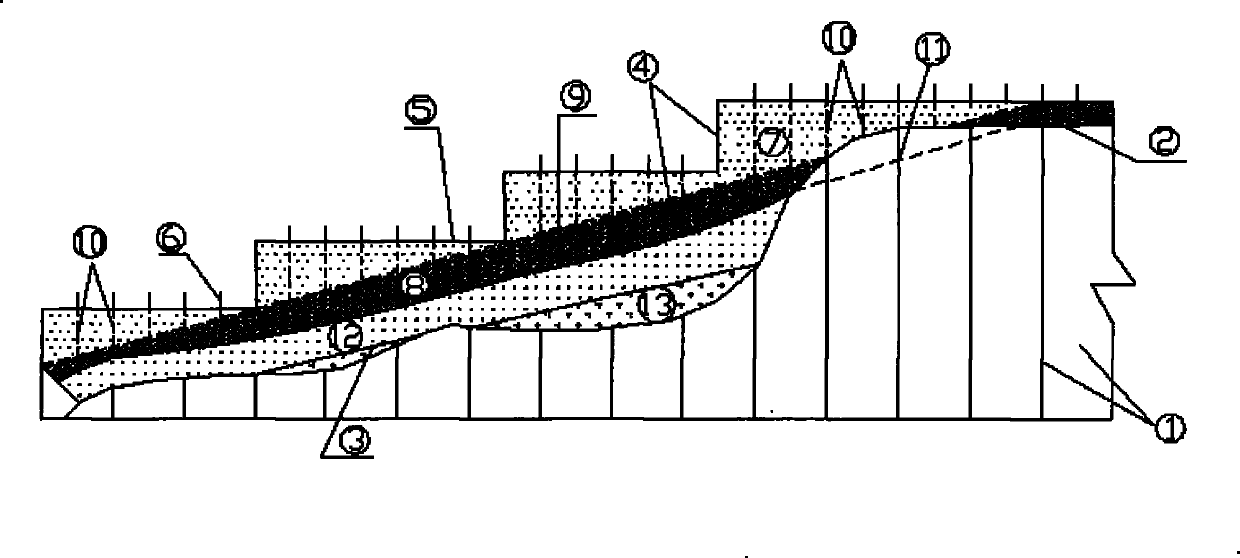

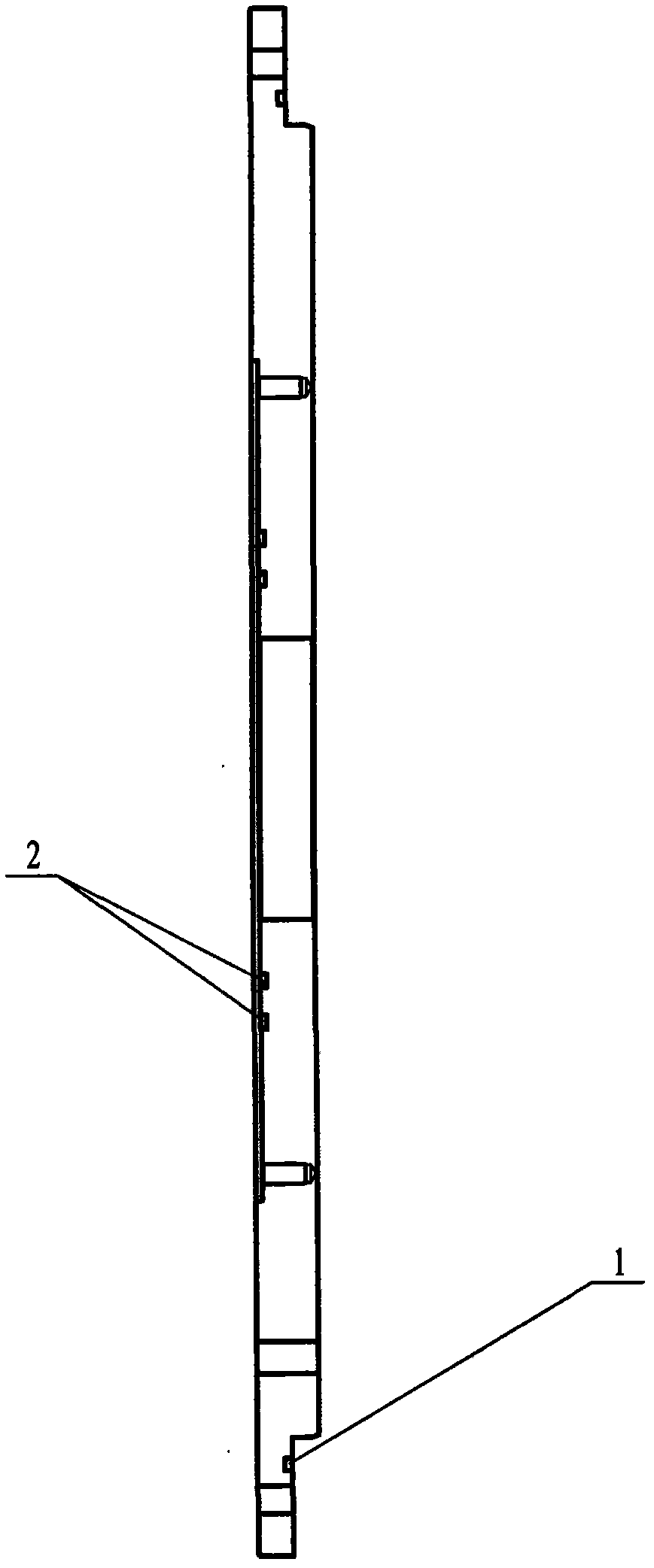

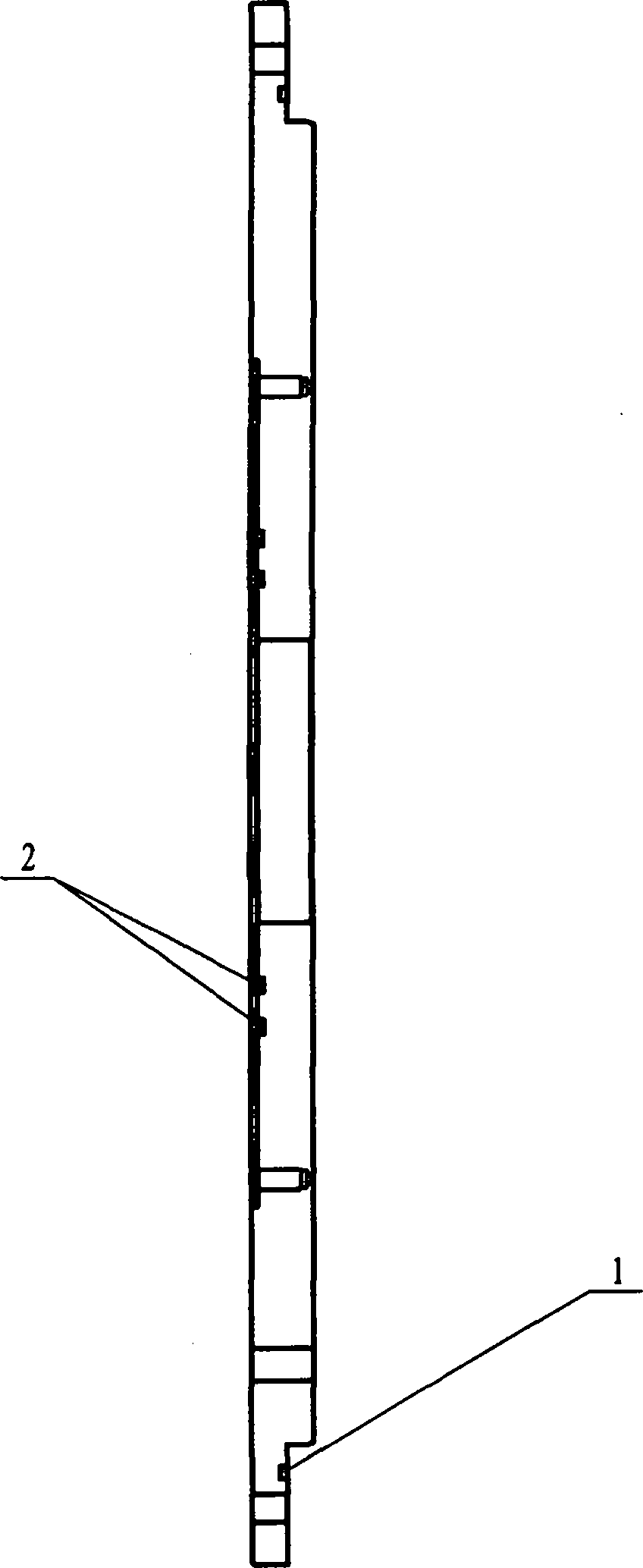

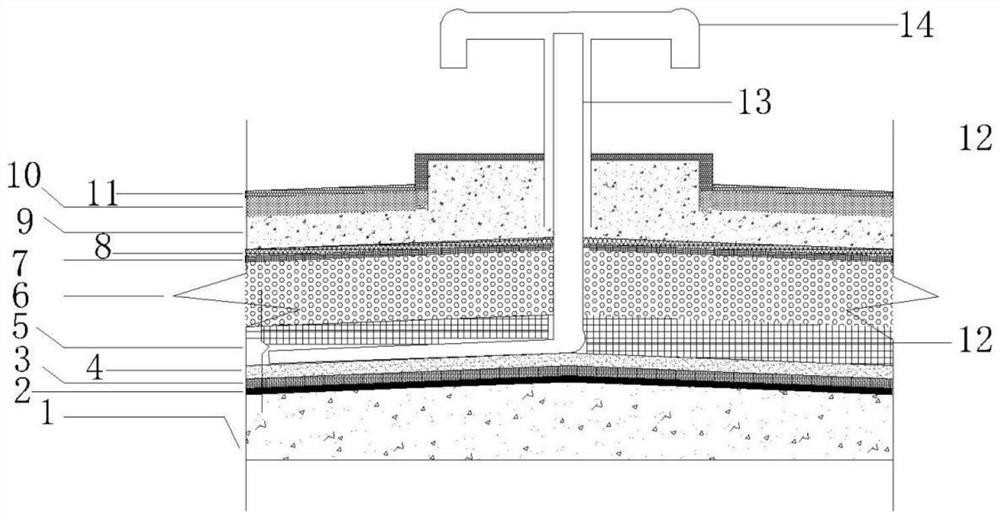

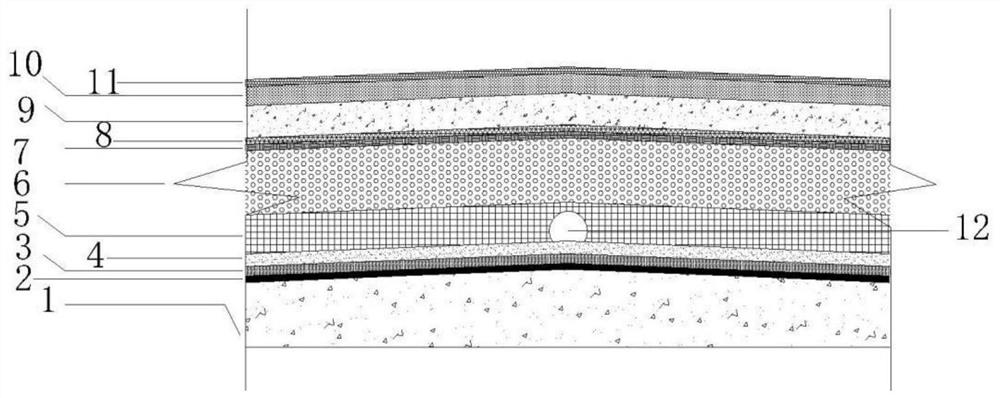

Waterproof plugging structure for roof pipeline and construction method

ActiveCN113374188AAchieve waterproof effectEnsure no leaksRoof covering insulationsSnow trapsSealantAsphalt

The invention discloses a waterproof plugging structure for a roof pipeline and a construction method, and belongs to the technical field of building construction. The waterproof plugging structure comprises a steel sleeve, first polymer waterproof mortar, a leveling layer, a waterproof coiled material, asphalt-based sealant, a galvanized pipe and second polymer waterproof mortar, wherein the steel sleeve is pre-buried in a roof structure layer and provided with a water stop wing ring; the first polymer waterproof mortar is poured between the steel sleeve and the roof pipeline; the leveling layer is laid on the roof structure layer; the waterproof coiled material is bonded to the upper surface of the leveling layer and the outer side of the steel sleeve; the asphalt-based sealant is sealed at the top of the waterproof coiled material and the top of the polymer waterproof mortar; the waterproof coiled material is sleeved with the galvanized pipe; a gap is reserved between the inner wall of the galvanized pipe and the waterproof coiled material; and the second polymer waterproof mortar is poured between the galvanized pipe and the waterproof coiled material and covers the top of the asphalt-based sealant. The waterproof effect of the roof pipeline is achieved through the measures of effectively plugging the space between the steel sleeve and the roof pipeline, turning the waterproof coiled material upwards to the top face of the steel sleeve, effectively protecting the waterproof coiled material turned to the steel sleeve and the like, and the pipeline is not leaked.

Owner:CHINA MCC17 GRP

Steel skeleton light-weight roof panel edge joint for integrated house

PendingCN110578387ADrain fastAvoid strandedRoof covering using slabs/sheetsRoof drainageArchitectural engineeringHooking

The invention discloses a steel skeleton light-weight roof panel edge joint for an integrated house, and belongs to the field of roof panel edge joints. The steel skeleton light-weight roof panel edgejoint comprises a first roof panel and a second roof panel, wherein a first connecting piece is fixed to the upper part of one side of the first roof panel; and a second connecting piece is fixed tothe lower part of one side of the second roof panel. During installation, a worker first aligns the first connecting piece with the second connecting piece, then inserts the first connecting piece into the inner side of the second connecting piece, clamps wing plates at the upper parts of the second roof panel and the first connecting piece, and finally fixes the wing plates through bolts, so thatthe steel skeleton light-weight roof panel edge joint is convenient to install. The steel skeleton light-weight roof panel edge joint has strong immobility through the mutual hooking and pulling between the first connecting piece and the second connecting piece. The steel skeleton light-weight roof panel edge join is based on the first connecting piece and the second connecting piece and is alsoprovided with a drainage channel and a sealant. The 100 percent no leakage of the edge joint can be ensured through the bending of the first connecting piece and the second connecting piece and the sealing of the sealant.

Owner:山东地球村集成房有限公司

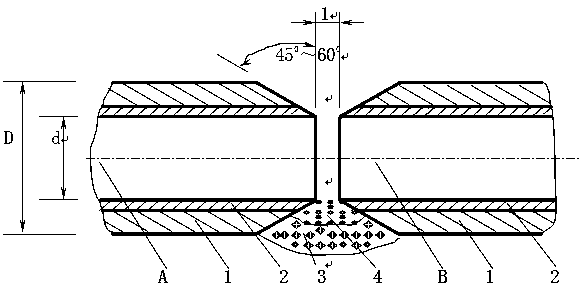

Direct connection welding mounting process for stainless steel-lined composite pipes

InactiveCN103737187AEasy and quick installation with direct connectionGuaranteed pureArc welding apparatusWelding/soldering/cutting articlesCorrosionMaterial selection

The invention discloses a direct connection welding mounting process for stainless steel-lined composite pipes. The process is characterized in that preparation before welding, welding material selection, a welding technology and the like are combined to realize direct connection welding mounting between the stainless steel-lined composite pipes. According to the process, the stainless steel-lined composite pipes can be conveniently rapidly and directly connected and mounted; an inner-layer pure stainless steel material after the welding of the stainless steel-lined composite pipes is integrated, so that the purity of a conveying medium after the direct connection welding mounting of the stainless steel-lined composite pipes is strictly ensured, and leakage and corrosion to pipe bodies after the direct connection welding mounting of the stainless steel-lined composite pipes are avoided.

Owner:WUHU XINLI PIPELINE TECH

A formwork support method for cast-in-place dome roof

ActiveCN102644373BReduce lossGuarantee molding qualityForms/shuttering/falseworksBuilding material handlingBolt connectionArc length

The invention discloses a formwork support method for a cast-in-place dome roof, which comprises the following steps: matching formwork and retaining construction joints; both inner and outer formworks are prefabricated on site in the form of enlarged samples, assembled in sections, and the height of each section is determined according to the specifications of the plywood. The arc length of the concrete horizontal joint construction is consistent with the height of the outer formwork of the dome hemisphere; the outer formwork and the inner formwork are connected by tension bolts, and when each section of concrete is poured, the construction joints of certain specifications of wood are prevented; Formwork back flute; configure curved panel and formwork installation. In this method, both the inner and outer formwork are prefabricated on site in the way of enlarged sample, assembled in sections, the inner formwork is assembled and installed to the top at one time, the outer formwork and concrete are constructed in sections, and the formwork is used repeatedly. The method has the characteristics of low material loss, reusable use, simple assembly, fast construction speed, easy quality assurance, low construction cost and high safety.

Owner:QINGJIAN GRP CO LTD

Novel high-medium-low-pressure wear-resisting double-gate-disc ash gate valve

The invention relates to a novel high-medium-low-pressure wear-resisting double-gate-disc ash gate valve. The gate valve comprises a valve body, two valve seats, a valve deck, gate discs and a driving mechanism of the gate discs and is characterized in that each valve seat is in the shape of a flange, the two valve seats are connected to the inner ends of flow channels on the two sides of the valve body respectively, an O-shaped sealing ring is arranged between each valve seat and a valve body contact surface, annular grooves corresponding to the valve seat sealing surfaces are formed in the two side faces of each gate disc respectively, hard alloy is arranged in each annular groove through bead welding, an inner annular groove and an outer annular groove are formed in each valve seat sealing surface, hard alloy is arranged in each inner annular groove through bead welding or a ceramic ring is embedded in each inner annular groove, and each outer annular groove is filled with a soft sealing ring. The gate valve is reasonable in structural design, reliable in use, and capable of fundamentally solving the problems of an existing ash gate valve that wearing occurs easily, sealing performance is poor, service life is short, maintenance is not easy, and using cost is high, wearing resistance and sealing performance are improved remarkably, service life is prolonged, and maintenance is facilitated.

Owner:LIAONING MINGDE MAGNETIC POWER TECH CO LTD

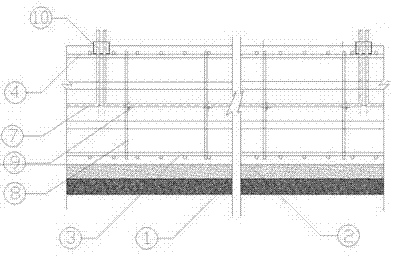

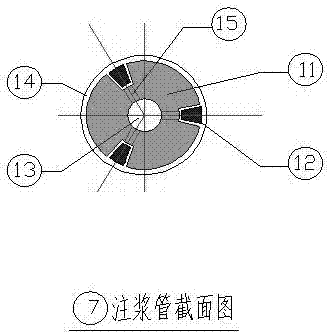

Grouting method for concrete raft foundation construction joint

InactiveCN107345405AMeasures to solve the pluggingPlugging is convenientArtificial islandsUnderwater structuresWater leakageReinforced concrete

The invention discloses a grouting method for a concrete raft foundation construction joint. On the basis of banding reinforced concrete raft foundation lower double-layer rebar and reinforced concrete raft foundation upper double-layer rebar, vertical rebar is welded, grouting pipes are laid in a middle rabbet groove of the concrete raft foundation construction joint at horizontal spacing of 500mm according to preset requirements, when a water leakage phenomenon occurs to molded concrete in the use process, the laid grouting pipes can be used for grouting caulking, technical problems which cannot be solved by conventional waterproof treatment are solved, quality is guaranteed, the construction period is shortened, cost is reduced, and the purpose of prevention and treatment integration is realized. Compared with a traditional joint treatment method, the grouting method has the advantages that not only is material performance excellent, installation is simple and convenient, the construction period is shortened, the cost is reduced, under the premise of not damaging the structure, it is ensured that no leakage occurs at the joint, and the grouting method is an advanced and effective joint waterproof measure.

Owner:CHINA MCC17 GRP

Design and implementation method of novel waterproof structure for building sedimentation post-cast strip

InactiveCN110117967AAvoid destructionGuaranteed functionArtificial islandsProtective foundationIsolation layerBuilding design

The invention aims to provide a design and implementation method of a novel waterproof structure for a building sedimentation post-cast strip. According to the technical scheme, building design, building construction and building material technologies are integrated, and the waterproof function of the building sedimentation post-cast strip is ensured. A first structure (a bottom plate post-cast strip structure at the junction of a high layer and a podium) of the building sedimentation post-cast strip mainly comprises five parts of a foundation mat layer, a sponge bar for increasing elongation,a waterproof coil layer, a sliding metal isolation layer and an expansion anti-permeable concrete layer.

Owner:安徽四建基础建设工程有限公司 +1

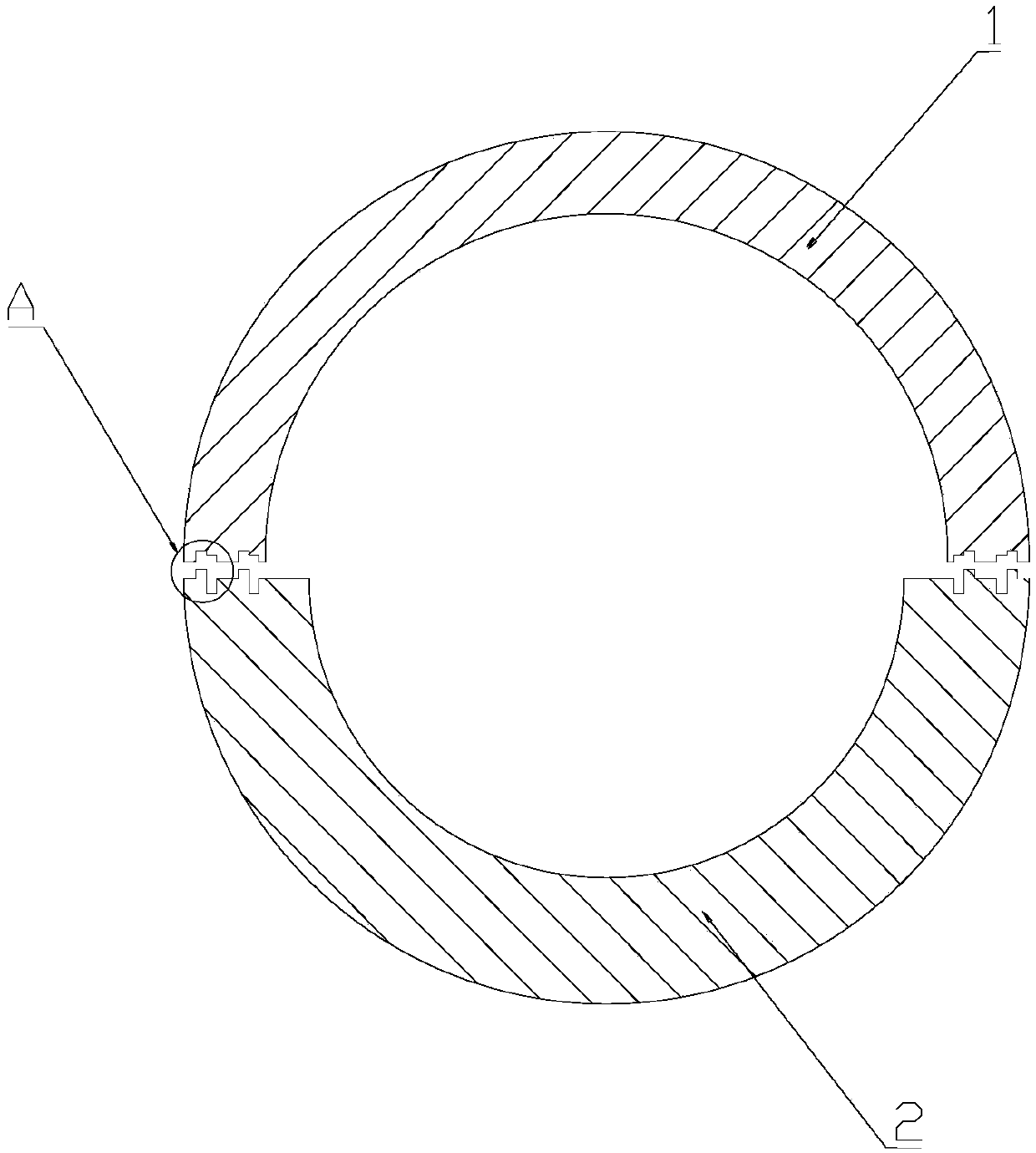

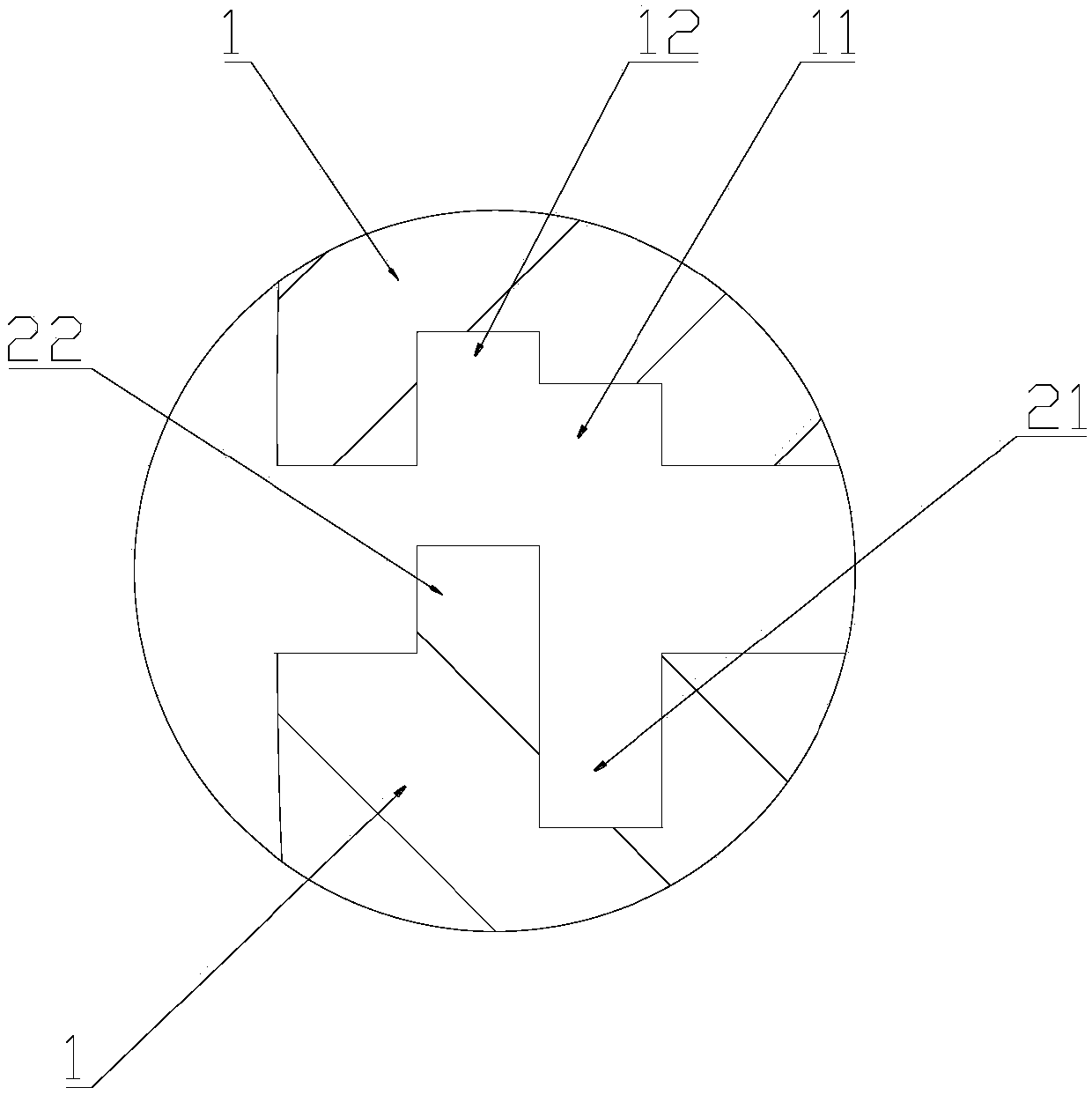

Anti-leakage and easy-to-replace drainage pipeline

InactiveCN110820892ALow costReduce the difficulty of replacementSewer pipelinesStructural engineeringSewage

The invention belongs to the technical field of drainage pipes, and particularly relates to an anti-leakage and easy-to-replace drainage pipeline. The anti-leakage and easy-to-replace drainage pipeline comprises a pipe body with a cylindrical shape, the pipeline body is formed by splicing an upper half shell and a lower half shell, at least one upper concave part is arranged at the two ends of theupper half shell in the radial direction, the upper concave parts are in a step shape, each upper concave part comprises a first groove and a second groove, the two ends of the lower half shell are provided with lower concave parts matched with the first grooves and convex parts matched with the second grooves, the first grooves and the lower concave parts are spliced to form first sealing grooves, and first sealing strips are arranged in the first sealing grooves. The leak-proof and easy-to-replace drainage pipeline has a good anti-leakage effect, can prevent the pavement from sinking, prevents the sewage from polluting the environment, and has a long service life.

Owner:汉江城建集团有限公司

No-leakage cyan-blue crack glaze ceramic vessel and production process thereof

The invention discloses a no-leakage cyan-blue crack glaze ceramic vessel. The no-leakage cyan-blue crack glaze ceramic vessel comprises a utensil firing part, an inner glaze layer is sprayed on the inner cavity surface of the utensil firing part, an outer glaze layer is dipped on the outer surface of the utensil firing part, the inner glaze layer is prepared from inner glaze frit, kaolin, alum blue material and copper oxide, and the outer glaze layer is prepared from outer glaze frit, kaolin, copper oxide and alum blue material. The invention also discloses a preparation process of the no-leakage cyan-blue crack glaze ceramic vessel. The invention discloses the no-leakage cyan-blue crack glaze ceramic vessel and the preparation process of thereof, wherein two sets of glazes with differentformulas are respectively used as the inner glaze layer and the outer glaze layer, when the finished product is manufactured, the outer glaze layer has the decorative effect to form the cracked glaze, and the inner glaze layer has the protective effect not to form the cracks, thereby ensuring that the ceramic vessel does not leak, and enable the ceramic vessel to be fired at the temperature of 1185 DEG C, and the finished product after firing is similar in color development.

Owner:潮州市长城世家瓷业有限公司

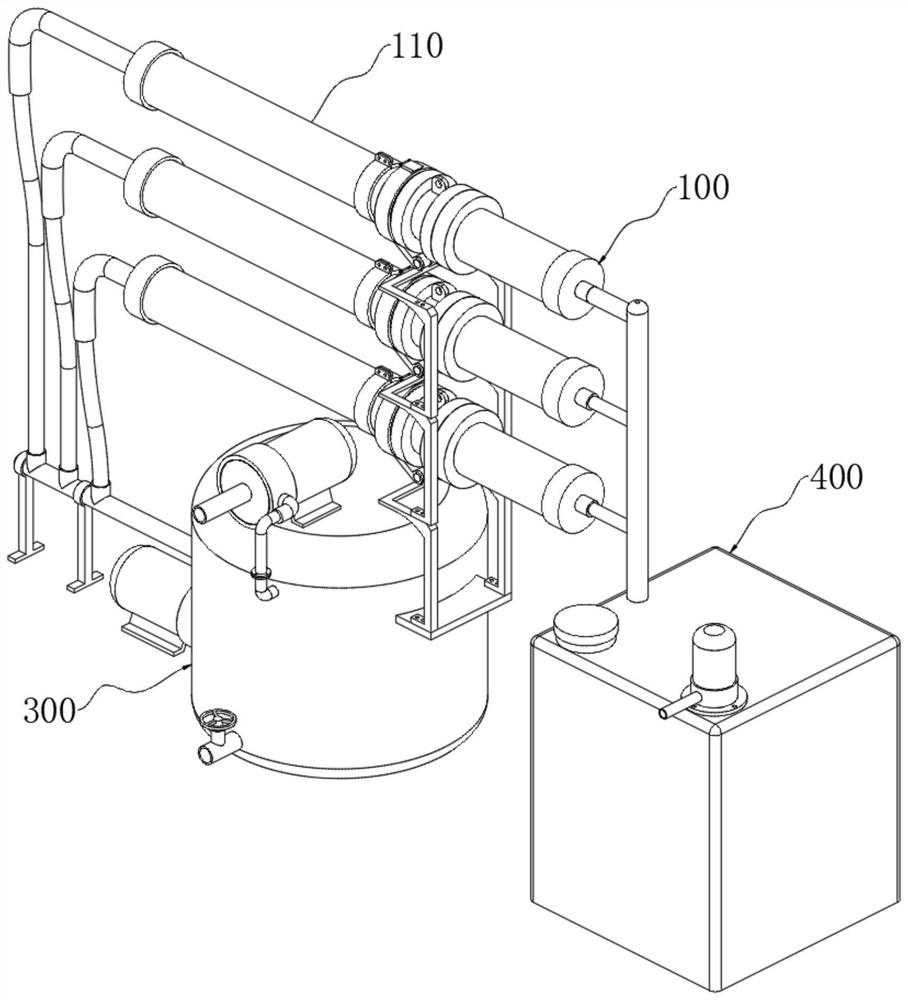

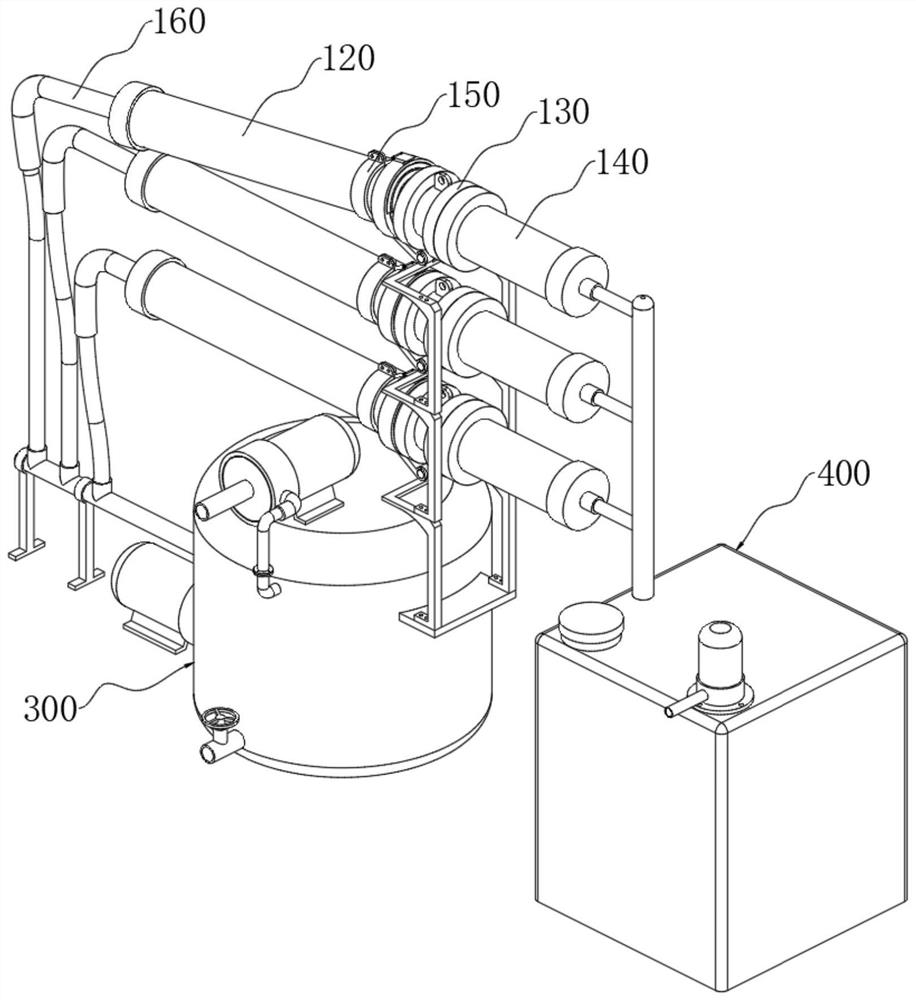

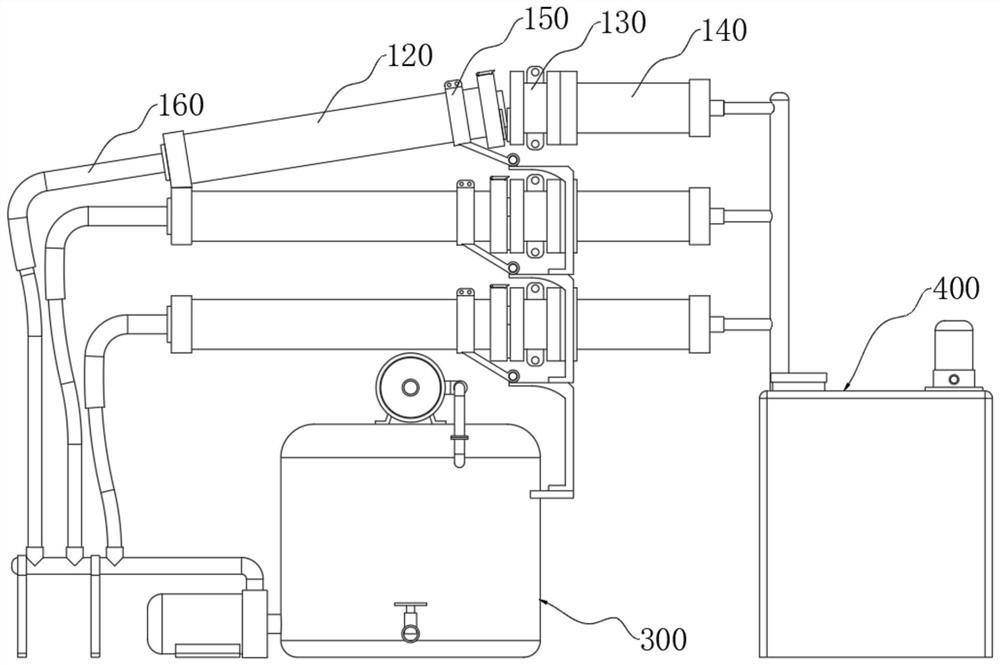

Reverse osmosis equipment with quick-release sewage cleaning mechanism based on reverse osmosis water treatment

InactiveCN112316733AIngenious structureEasy to useReverse osmosisMultistage water/sewage treatmentReverse osmosisSewage

The invention discloses reverse osmosis equipment with a quick-release sewage cleaning mechanism based on reverse osmosis water treatment. The reverse osmosis equipment comprises a reverse osmosis device and the sewage cleaning mechanism mounted on one side of the reverse osmosis device, the reverse osmosis device is composed of a plurality of reverse osmosis assemblies from bottom to top, and each reverse osmosis assembly comprises a long osmosis pipe, a reverse osmosis pipe and a short osmosis pipe which are coaxially and sequentially connected; the sewage cleaning mechanism comprises a sewage tank, a rotating shaft arranged above the sewage tank and a sewage cleaning shovel; the middle part of the inner wall of a sewage cleaning pipe is closed, and a servo motor for driving the rotatingshaft to rotate is arranged in an inner cavity close to the right end. According to the reverse osmosis device, the long osmosis pipes, the reverse osmosis pipes and the short osmosis pipes are arranged to form the reverse osmosis assemblies, the long osmosis pipes can be rapidly detached from the reverse osmosis pipes so that a reverse osmosis membrane can be cleaned or replaced in time, sewageobtained after the long osmosis pipes are cleaned is collected through the sewage cleaning mechanism, and only the reverse osmosis pipes need to be replaced with the sewage cleaning pipe; and then theservo motor is started to drive the sewage cleaning shovel to shovel off attachments on the inner walls of the long seepage pipes, the automation efficiency is high, and a large amount of working time is saved.

Owner:方明科

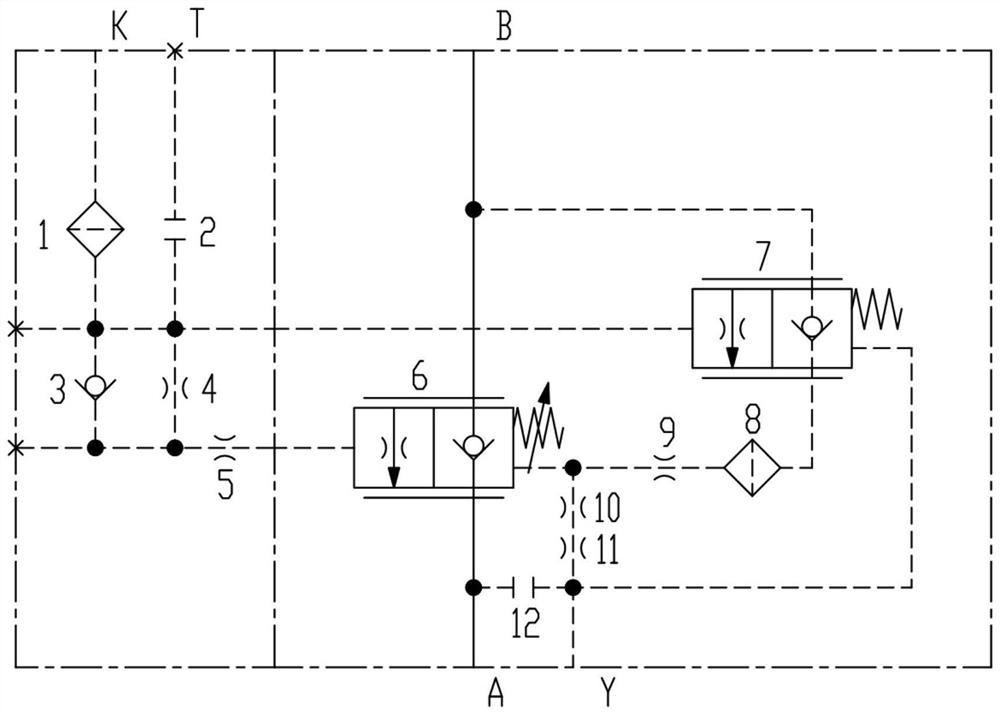

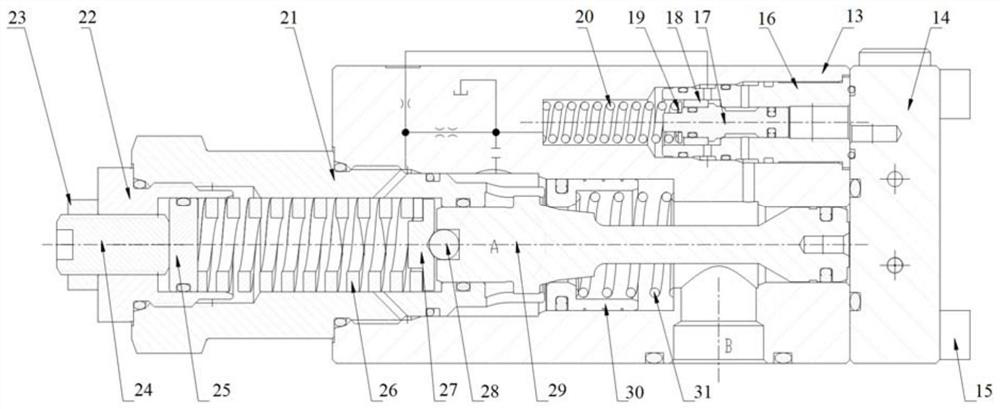

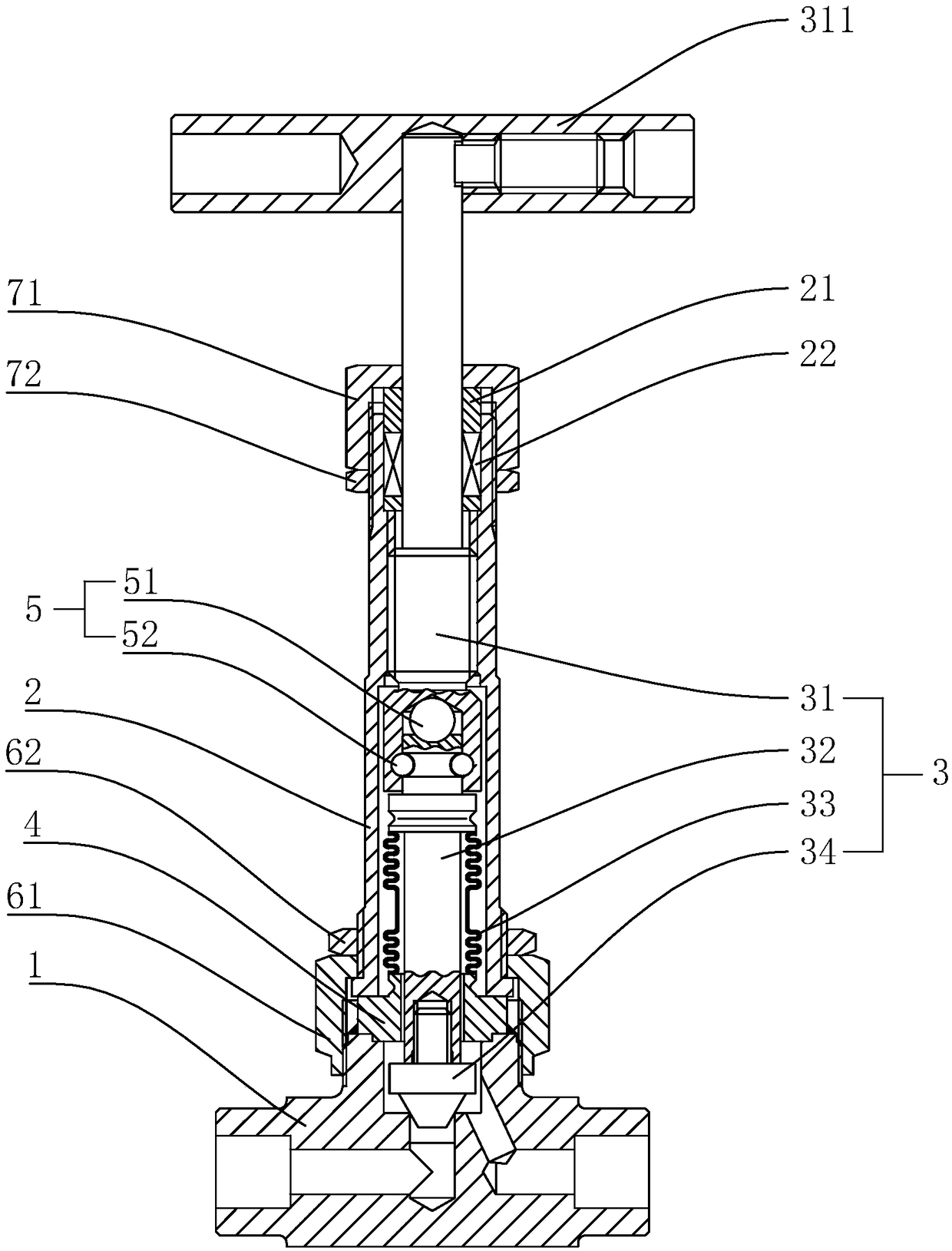

Loading pressure-flow compensation balance valve

ActiveCN111810481AEasy to replaceEasy to assemble and disassembleServomotor componentsCranesEngineeringDamper

The invention discloses a loading pressure-flow compensation balance valve. The loading pressure-flow compensation balance valve comprises a balance valve body, wherein a control end cover is installed on the balance valve body, an opening K of the control end cover is used for receiving control pressure from variable-amplitude falling, and is connected with a one-way valve, a first damper, one end of a first screwed plug and a two-position two-way reversing valve through a first filter screen, the one-way valve and the other end of the first damper are connected together and connected to a control cavity of a balance valve through a second damper, one end of the balance valve is connected with a variable-amplitude oil cylinder through a balance valve opening B, the other end of the balance valve is connected with a control valve through a balance valve opening A, spring cavities of the balance valve are connected with one end of a third damper and one end of a fourth damper correspondingly, the other end of the fourth damper and a fifth damper are connected in series and then are connected with one end of a second screwed plug, a spring cavity of the two-position two-way reversingvalve and a balance valve opening Y, and one oil end of the two-position two-way reversing valve is connected with the balance valve opening B. The loading pressure-flow compensation balance valve has the advantages of being simple in product structure, low in cost, good in compensation effect and capable of being adjusted conveniently.

Owner:JIANGSU ADVANCED CONSTR MASCH INNOVATION CENT LTD +1

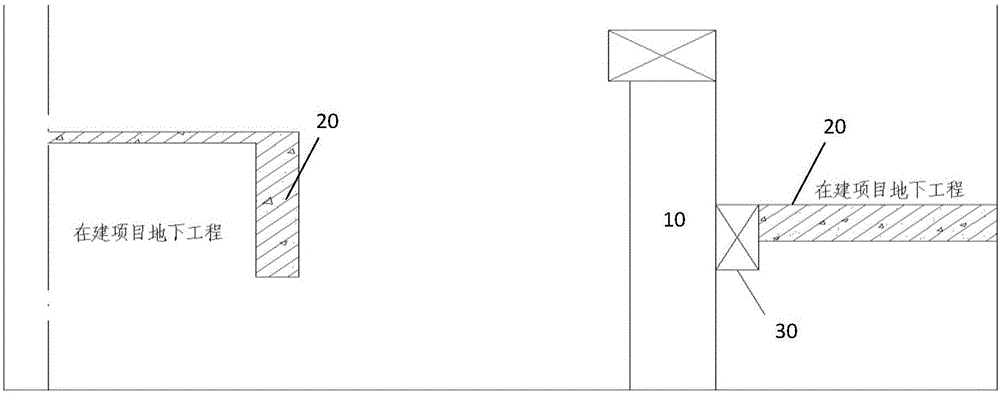

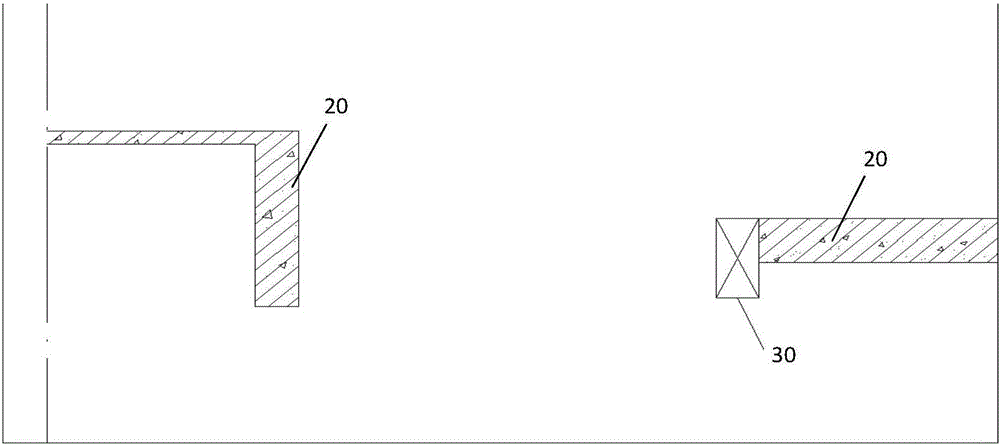

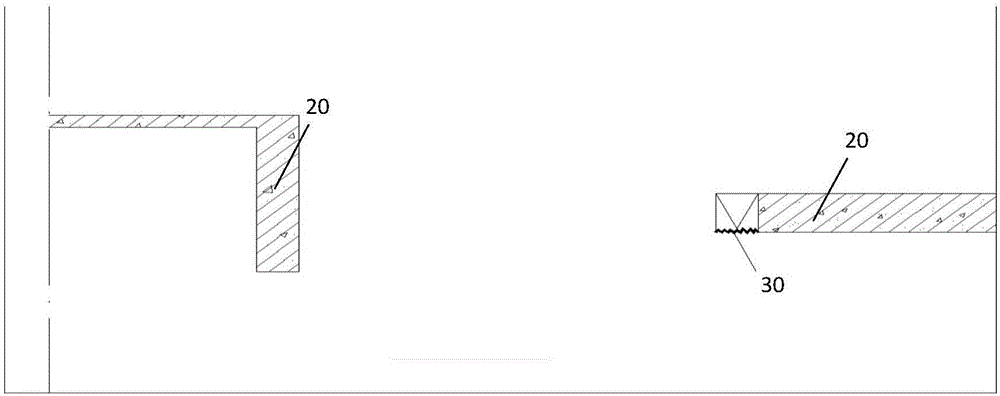

Basement communication method

The invention discloses a basement communication method. The basement communication method comprises the steps that firstly, a temporary structural beam (30) is arranged between a lining wall (20) of one basement and an enclosing wall (10); secondly, the enclosing wall (10) between lining walls (20) of two basements is dismantled; thirdly, part of the temporary structural beam (30) is dismantled; and fourthly, a connecting channel top plate (40) is constructed between the lining walls (20) of the two basements and fixedly connected with the temporary structural beam (30). By adoption of the basement communication method, the temporary structural beam (30) is incompletely dismantled, so that structural floors of the basements are not overhung, the safety of the structural floors is improved, and environmental-friendly construction requirements are met.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

A processing technology of cracked celadon cosmetic bottle with inner surface non-cracked glaze

ActiveCN110228993BImprove display effectOvercome the defect that the green body is easy to be crackedCeramic materials productionClaywaresCosmetic appearanceComposite material

Owner:龙泉市青瑜瓷坊

Method for installing externally connected hose of toilet bowl and combined spanner special for externally connected hose

The invention relates to the method for installing an externally connected hose of a toilet bowl in bathroom decoration engineering and further relates to a combined spanner special for the externally connected hose. An installation spanner special for the externally connected hose of the toilet bowl is not available on the market currently. Due to the fact that the installation space around the toilet bowl is narrow, force can not be exerted in the direction perpendicular to the axial direction of connection of a loose joint nut through a common spanner, and assembly and disassembly are conducted for multiple times, so that connecting pieces such as an angle valve are prone to damage. The loose joint nut on the externally connected hose is tightly pressed through the combined spanner special for the externally connected hose, so that assembly and disassembly of the loose joint nut is convenient like those of a butterfly nut.

Owner:李秀菊

Method for manufacturing conducting solution simulation test model for studying three-dimensional seepage field of dam

The invention relates to a method for manufacturing a conducting solution simulation test model for studying a three-dimensional seepage field of a dam, which is characterized in that the conducting solution simulation test model integrates the terrain, the dam structure, the measuring point and other arrangements into a whole and can meet the test requirement without rotating and cutting a prototype. The conducting solution simulation test model is used for point testing and three-dimensional seepage surface arranging and overcomes the defects that a traditional model needs to penetrate through an internal structure to collect information on the elevation and the potential of the seepage surface; a seepage preventing ring made of strip-shaped watertight soft material ensures that the conducting solution of the conducting solution simulation test model can not seep and an electric field of the conducting solution simulation test model is undistorted; and the conducting solution simulation test model is made of conventional material, is strongly intuitive in appearance and is convenient for test, measurement and repair.

Owner:HOHAI UNIV

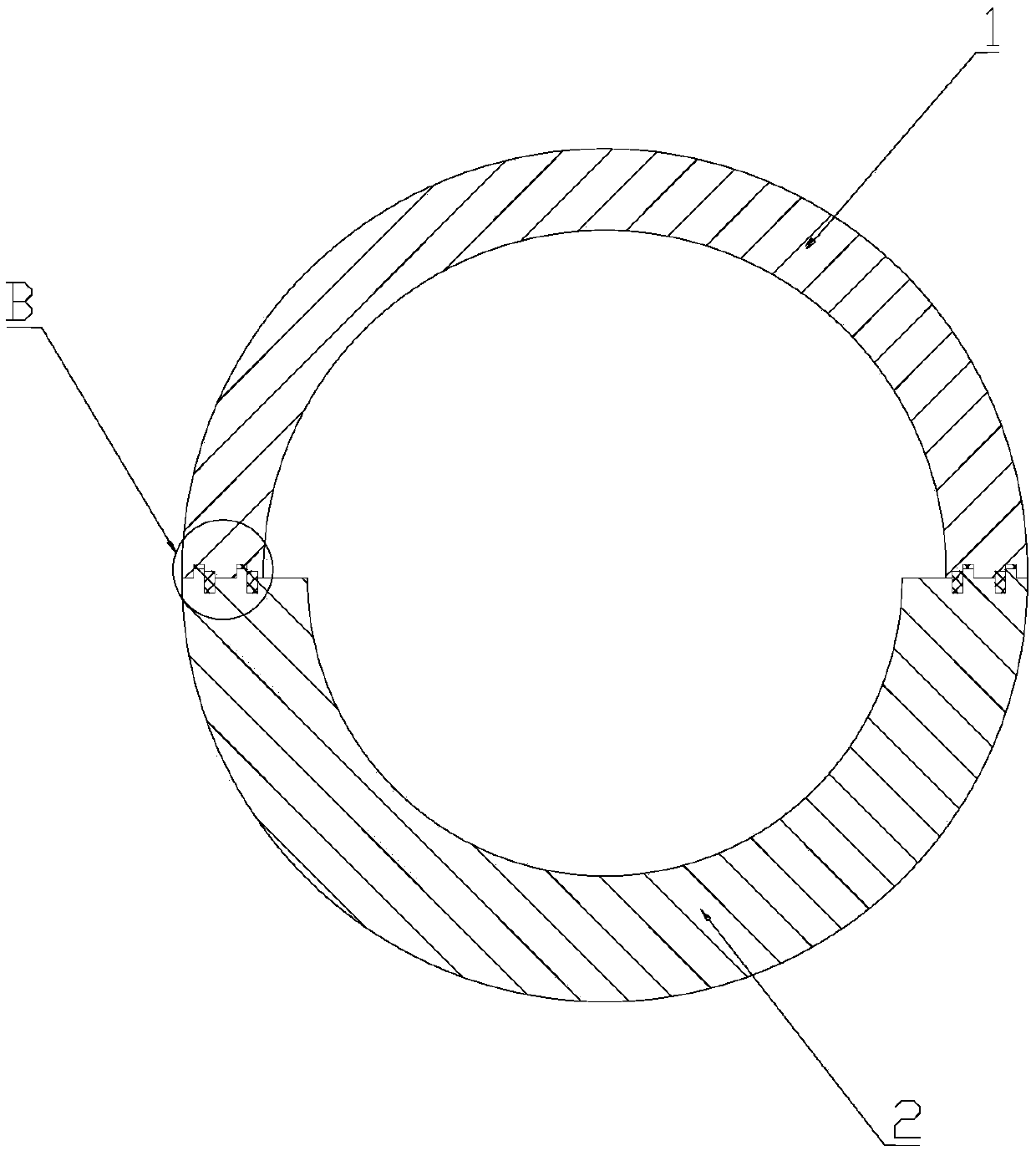

Upper cover plate sealing device of full automatic sewage removing machine

InactiveCN102139174AEnhanced static sealing performanceGuaranteed seal lifeEngine sealsMoving filtering element filtersCorrosionSewage

The invention discloses an upper cover plate sealing device of a full automatic sewage removing machine. An upper cover plate of the full automatic sewage removing machine is provided with three O-shaped ring grooves, wherein the first ring groove is positioned at the joint of a shell and the upper cover plate, namely an O-shaped ring groove (1) is positioned at the joint of the upper cover plate and the shell; the second ring groove and the third ring groove are positioned at the joint of the top of the upper cover plate and an upper decelerator connecting seat, namely two O-shaped ring grooves (2) are positioned at the joint of the upper cover plate and the upper decelerator connecting seat; and the inner sides of the three O-shaped ring grooves are provided with small chamfers. By processing the three O-shaped ring grooves, the static sealing performance of the upper part of the full automatic sewage removing machine is enhanced, the sealing life of the full automatic sewage removing machine is ensured in high-corrosion sewage, no leakage of the full automatic sewage removing machine is ensured in a pressure environment, and the installation and maintenance processes of the upper cover plate become simpler and more convenient.

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

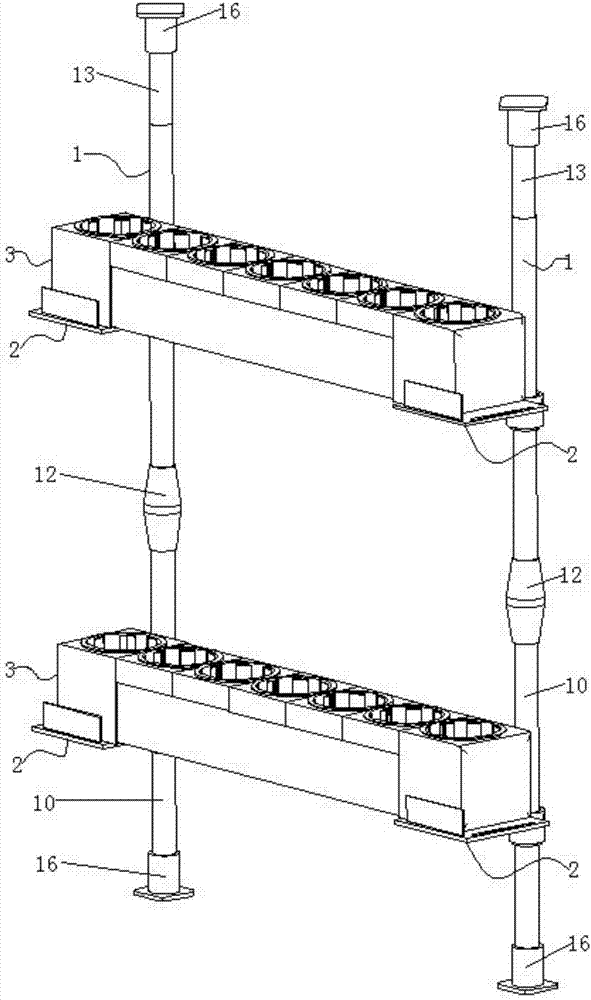

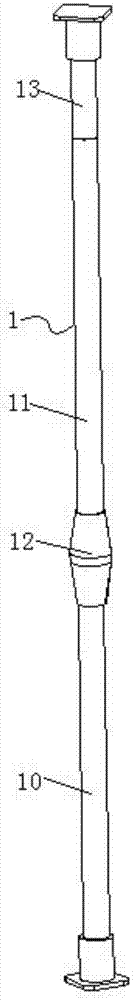

Inverted type person-bearable facing brick roof concealed buried exhaust pipeline invisible structure and construction method thereof

ActiveCN113006388AScientific and reasonable design settingsRigorous processLighting and heating apparatusBuild-up roofsRubberized asphaltRebar

The invention discloses an inverted type person-bearable facing brick roof concealed buried exhaust pipeline invisible structure and a construction method thereof. The inverted type person-bearable facing brick roof concealed buried exhaust pipeline invisible structure comprises a steel bar structure concrete roof, a sprayed non-cured rubber asphalt waterproof coating, a self-adhesive 1.5mm-thick tire-free high polymer modified asphalt waterproof coiled material, a 20-thick 1:3 cement mortar leveling layer, a point-adhesive 60-thick extruded polystyrene foam plastic plate for heat insulation, the thinnest 30-thick LC5.0 light aggregate concrete, a full-laid non-woven fiber cloth layer, a steel bar mesh, a 50-thick C20 fine aggregate concrete leveling layer, a roller-coated waterproof polymer layer and 8-10-thick facing anti-skid floor tiles which are sequentially arranged from the bottom layer to the top layer of the roof, and further comprises an oval PVC gas collecting flow guide pipe and an exhaust vertical pipe, wherein the oval PVC gas collecting flow guide pipe is horizontally arranged between the cement mortar leveling layer and the non-woven fiber cloth. According to the inverted type person-bearable facing brick roof concealed buried exhaust pipeline invisible structure and the construction method thereof, exhaust is smooth and free of blockage, water stains seeping from a construction layer above a part of heat preservation layer and condensate water in the heat preservation layer can be quickly guided and discharged in time, the comprehensive construction cost is low, and the service life of the roof is prolonged.

Owner:WUHAN CONSTR ENG

A kind of pipe fitting processing technology

Owner:JIAXING MASTER PLUMBING

Indoor-plant planting wall easy and convenient to install

PendingCN107509629AEasy to installVarious combinationsAgriculture gas emission reductionCultivating equipmentsEngineeringScrew thread

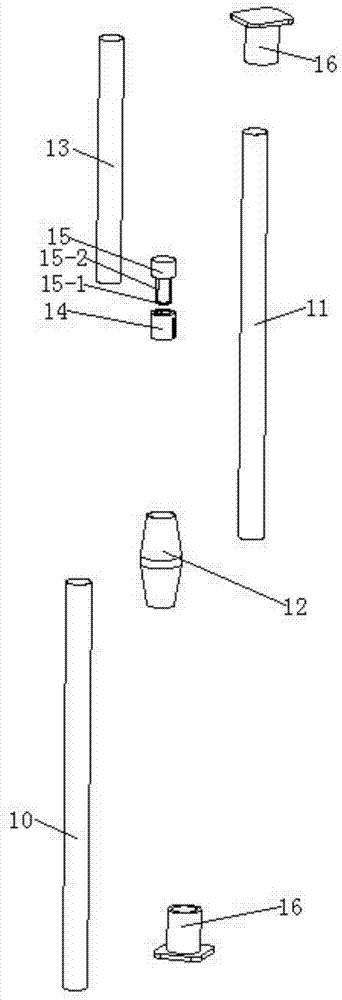

The invention discloses an indoor-plant planting wall easy and convenient to install. The indoor-plant planting wall easy and convenient to install comprises steel pipe columns, tray assemblies and planting troughs. The tray assemblies are connected with the steel pipe columns, one ends of the planting troughs are connected with the tray assemblies on one steel pipe column, and the other ends of the planting troughs are connected with the tray assemblies on the other steel pipe column; the steel pipe columns are composed of first steel pipes, second steel pipes, connecting sleeves, third steel pipes and head sleeves; the tray assemblies are composed of inner ring sleeves, outer ring sleeves, trays and baffles, wherein tapers are arranged on the outer surfaces of the inner ring sleeves, outer threads are formed in the outer surfaces of the inner ring sleeves, inner threads are formed in the outer ring sleeves, and the inner threads in the outer ring sleeves are connected with the outer threads in the outer surfaces of the inner ring sleeves through screw pairs; the planting troughs are composed of water tanks, water tank heads, upper water tank covers and plant baskets. The indoor-plant planting wall is rapid in installation and fast and convenient to adjust, plant replacement is easy and convenient, diverse plant combinations are achieved, and the freedom is high.

Owner:黄富滨

Novel double-sealed instrument block valve

InactiveCN109139935AImprove sealingDifficult to enterSpindle sealingsLift valveBlocked valvesEngineering

The invention discloses a novel double-sealed instrument block valve, and relates to the technical field of industrial automation. According to the novel double-sealed instrument block valve, a sealing ring disposed between an upper valve rod and the inner wall of a valve cover initially ensures the sealing property of the inner wall of the valve cover, at the same time, the sealing ring is further filled with sealing packing so as to fully cover the upper valve rod, the sealing property is further improved, and since the upper valve rod is rotatably connected into the valve cover, the upper valve rod only rotates without generating displacement in other directions, so that only the mutual movement between the upper value rod and the sealing packing in the circumferential direction is generated, and the sealing effect of the sealing packing is more stable and long-lasting. A metal corrugated tube can be both compressed and stretched, the own elastic deformation of the metal corrugatedtube realizes the movement of the valve core, and a medium is completely sealed in a closed cavity formed by the metal corrugated tube and the valve cover, the contact between the medium and the sealing packing is blocked, and no leakage of a packing sealing part is achieved.

Owner:JIANGSU HUATAI ELECTRIC POWER ELECTRONICS INSTR

Casting technology of square ram of numerical control gantry machining center

InactiveCN110014127AEasy to operateIncrease productivityFoundry mouldsFoundry coresNumerical controlHigh volume manufacturing

The invention relates to the technical field of square ram casting, and discloses a casting technology of a square ram of a numerical control gantry machining center. The casting technology comprisesthe following steps of: step one. fixing a square ram manufacturing mold by adopting a horizontal moulding and pouring formative technology; step two. dividing a loam core of the inner cavity of the mold into multiple sections according to the structure, designing core prints on a window of the upper plane of the mold; step three. smelting by using an electric furnace smelting technology of smelting a high-strength gray pig iron with high carbon equivalent; step four. pouring molten iron smelted in the step three into the mold; and step five. processing a finished product, taking out a crude product, and then carrying out four-corn quenching, coarse grinding and fine grinding on the crude product to obtain the finished product. The casting technology of the square ram of the numerical control gantry machining center can produce large-batch square ram castings of machine tools with stable quality and high rate of finished products through horizontal moulding and pouring and suspended core processes in combination with the electric furnace smelting technology of smelting the high-strength gray pig iron with high carbon equivalent, is simple to operate and has high production efficiency.

Owner:芜湖久弘重工股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com