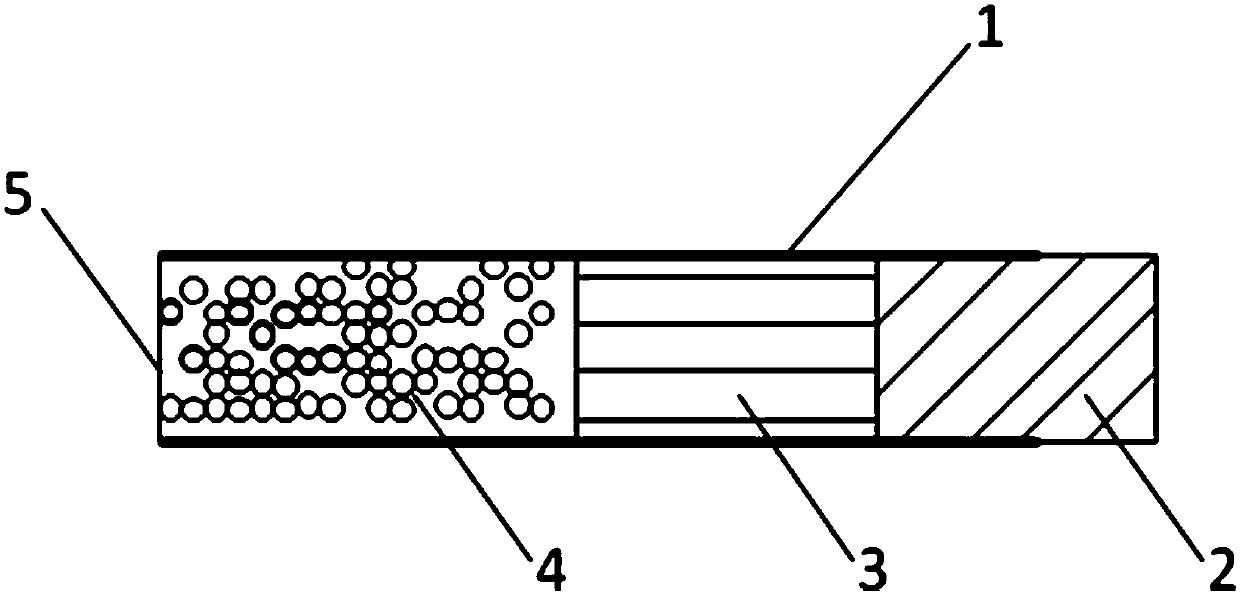

Non-rolled novel tobacco product containing tobacco particle material

A technology of tobacco granules and tobacco products, which is applied in the direction of tobacco, flat products, smokers' supplies, etc. It can solve the problems of poor controllability, uneven smoke generation, and affecting taste, so as to achieve better comfort and better taste , the effect of novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The air-permeable sheet-like material of this embodiment is laminated with a layer of graphene film on the ultra-fine glass fiber cotton, and is blocked at the tail end of the paper empty tube with the graphene film facing inward. The air-permeable sheet-like material has a value of 1200 cm in the thickness direction expressed by the Fraser number measured in accordance with JIS L1096. 3 / (cm 2 · seconds) air permeability.

[0033] The breathable sheet material of the present embodiment is made as follows:

[0034]A. Make superfine glass fiber cotton from ultrafine glass fibers with a diameter of 0.1-1 μm on the forming net;

[0035] B. Bombard the graphene film with a pulsed laser along the thickness direction to increase the gas permeability of the graphene film. The specific parameters are as follows: laser wavelength 532nm, energy 375mJ, pulse width 5ns, focused beam spot 0.35mm, bombardment frequency 3.5Hz; The laser beams are arranged linearly in the horizontal...

Embodiment 2

[0040] The air-permeable sheet-like material of this embodiment is laminated with a layer of graphene film on the ultra-fine glass fiber cotton, and is blocked at the tail end of the paper empty tube with the graphene film facing inward. The air-permeable sheet-like material has a thickness of 200 cm expressed by the Fraser number measured in accordance with JIS L1096. 3 / (cm 2 · seconds) air permeability.

[0041] The breathable sheet material of the present embodiment is made as follows:

[0042] A. Make superfine glass fiber cotton from ultrafine glass fibers with a diameter of 0.1-1 μm on the forming net;

[0043] B. Bombard the graphene film with a pulsed laser along the thickness direction to increase the air permeability of the graphene film. The specific parameters are as follows: laser wavelength 532nm, energy 400mJ, pulse width 4ns, focused beam spot 0.4mm, bombardment frequency 3Hz; multi-beam The lasers are arranged linearly in the horizontal direction, the dist...

Embodiment 3

[0048] The air-permeable sheet-like material of this embodiment is laminated with a layer of graphene film on the ultra-fine glass fiber cotton, and is blocked at the tail end of the paper empty tube with the graphene film facing inward. The air-permeable sheet-like material has a thickness of 2000 cm expressed by the Fraser number measured in accordance with JIS L1096. 3 / (cm 2 · seconds) air permeability.

[0049] The breathable sheet material of the present embodiment is made as follows:

[0050] A. Make superfine glass fiber cotton from ultrafine glass fibers with a diameter of 0.1-1 μm on the forming net;

[0051] B. Bombard the graphene film with a pulsed laser along the thickness direction to increase the air permeability of the graphene film. The specific parameters are as follows: laser wavelength 532nm, energy 300mJ, pulse width 6ns, focused beam spot 0.3mm, bombardment frequency 5Hz; multi-beam The lasers are arranged linearly in the horizontal direction, the dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com