Reverse osmosis equipment with quick-release sewage cleaning mechanism based on reverse osmosis water treatment

A reverse osmosis water, quick-release technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. problem, to achieve the effect of saving working time, ingenious structure, simple and fast cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

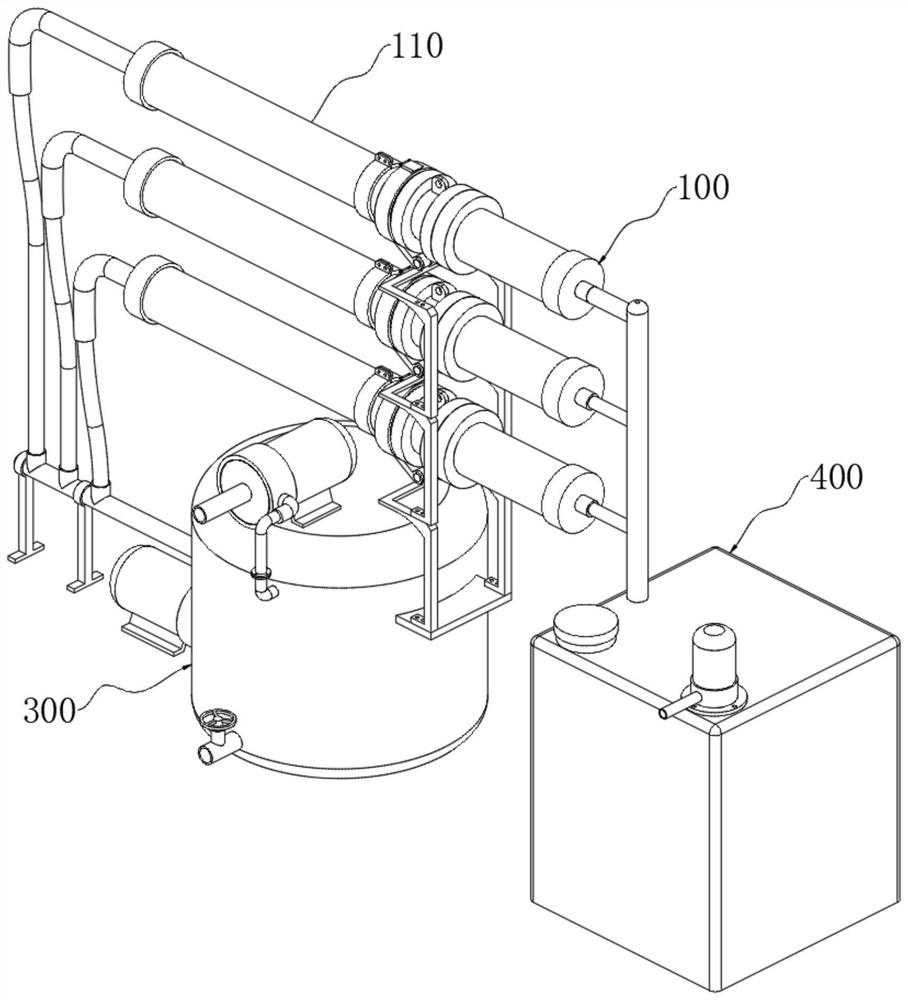

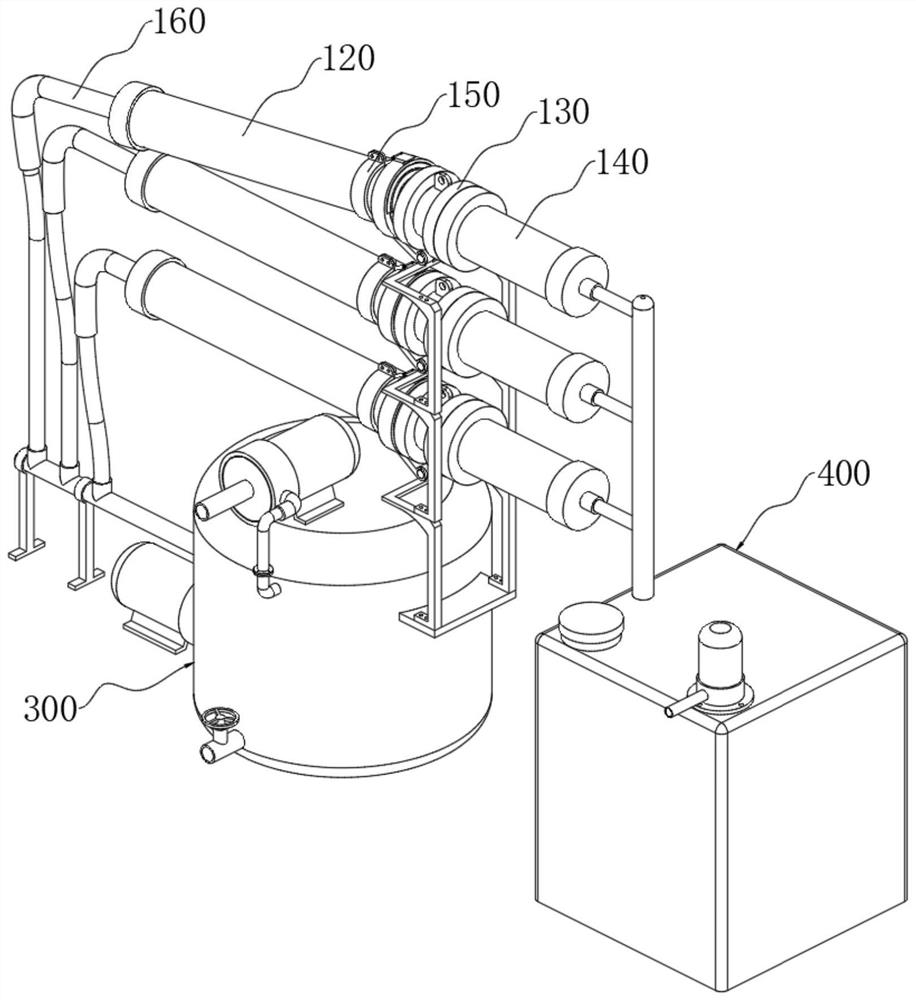

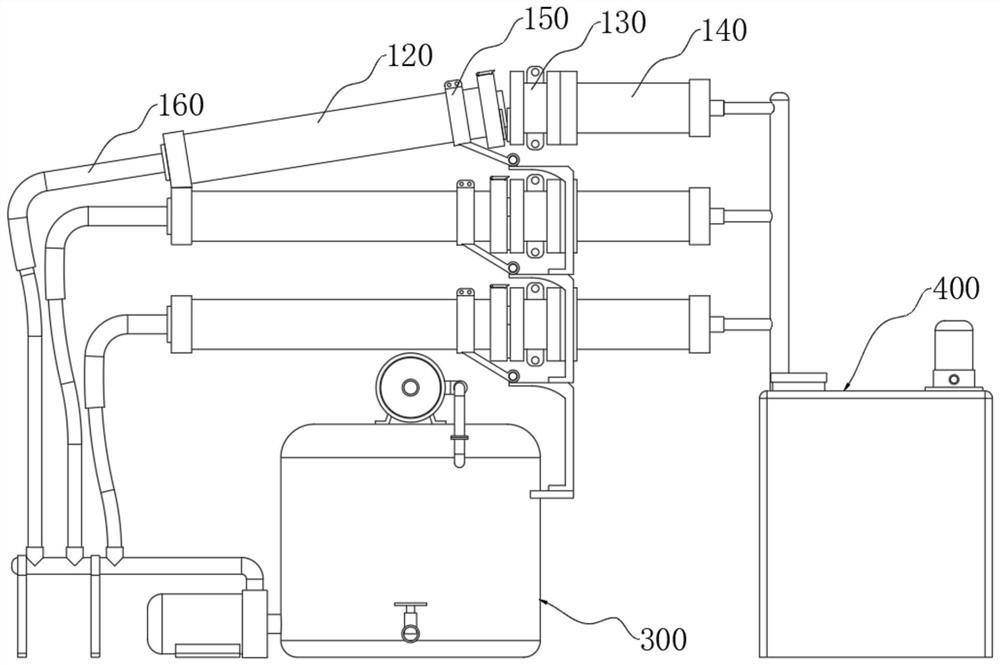

[0059] see Figures 1 to 24 As shown in the figure, the present invention provides a reverse osmosis equipment with a quick-release decontamination mechanism based on reverse osmosis water treatment, including a reverse osmosis device 100 and a decontamination mechanism 200 installed on one side thereof. The reverse osmosis device 100 is composed of several reverse osmosis components 110 from bottom to top. The reverse osmosis assembly 110 includes a long infiltration pipe 120 coaxially connected in sequence, a rotatable and detachable reverse osmosis pipe 130 and a short infiltration pipe 140, wherein the reverse osmosis pipe 130 can be disassembled so as to replace and remove the accumulated sludge. The axial section of the reverse osmosis pipe 130 is I-shaped and its inner wall is equipped with a reverse osmosis membrane 135. The reverse osmosis membrane is an artificial semipermeable membrane with certain characteristics made by simulating a biological semipermeable membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com