Method for manufacturing conducting solution simulation test model for studying three-dimensional seepage field of dam

A technology for test models and production methods, which is applied to teaching models, educational tools, instruments, etc., can solve problems such as three-dimensional seepage fields of dams with complex geometric shapes and internal structures, and achieve shortened test periods, strong intuitiveness, and improved test accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

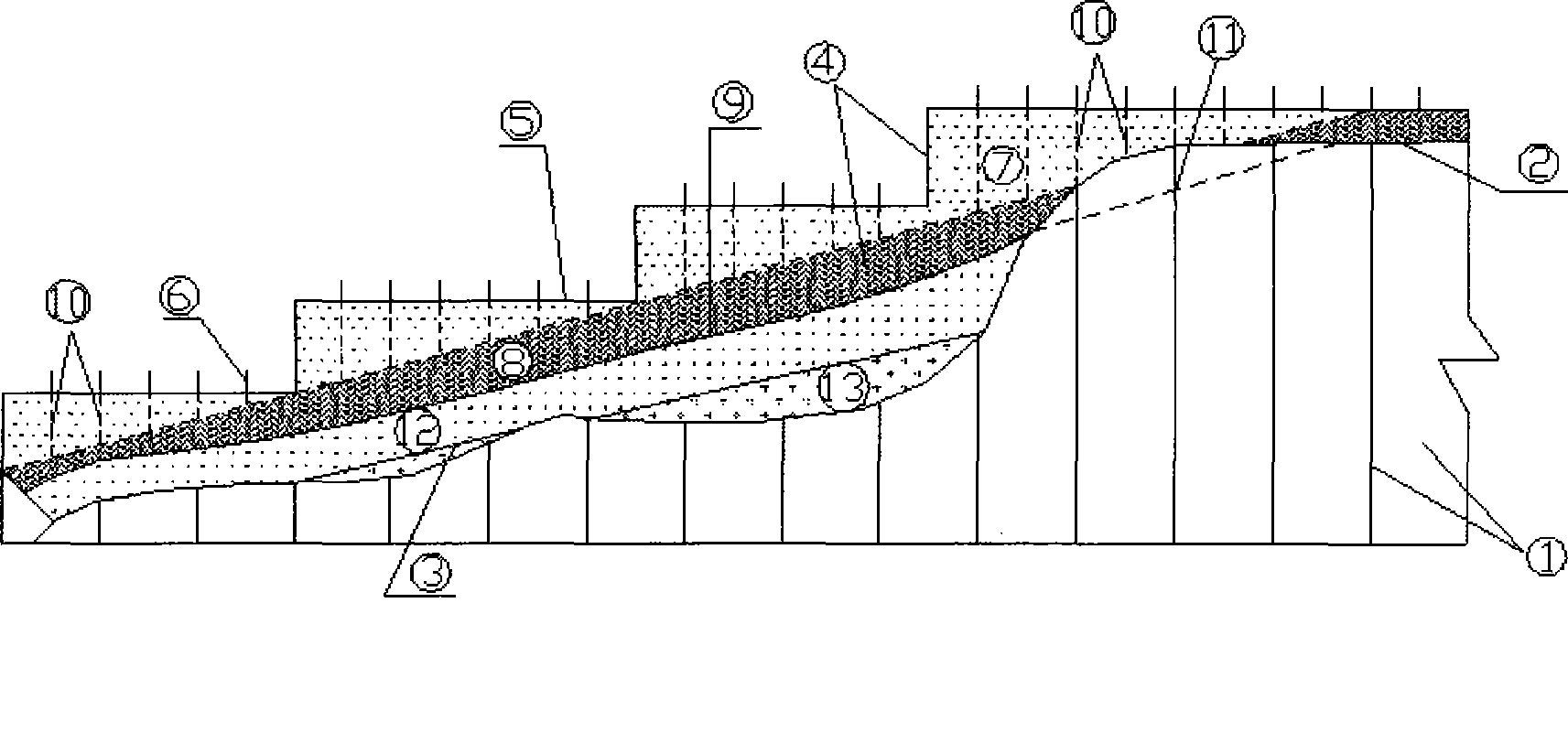

[0028] 1) Construct the terrain shape grid ① (made of wooden boards) the upper part is cut according to the topographical coordinates, and the lower part takes the unified base coordinates. After drawing grooves in the upper part of the longitudinal grating and the lower part of the horizontal grating respectively, the vertical and horizontal gratings are inserted into the grooves to form an overall grid terrain grating; the topography covering the terrain grating ② Select insulating soft cloth material , After soaking in epoxy resin solution, cover the topographic grid. When covering, the surface of each grid should be flat and smooth to prevent the resin liquid from accumulating in the concave area.

[0029] 2) The liquid barrier ③ is made of about 5mm plexiglass plate, on which the plum blossom-shaped holes with a diameter of 1mm are drilled at a certain density, and conductive copper wires are embedded in the holes, and the two ends are flush with the surface of the plexig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com