Replaceable air chamber mechanism used in ink supply system of ink-jet printer

An inkjet printer and air chamber technology, which is applied in the field of replaceable air chamber mechanism, can solve the problems of parts scrapping, plastic parts scrapping, increasing costs, etc., and achieve the effects of cost avoidance, mold design simplification, and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

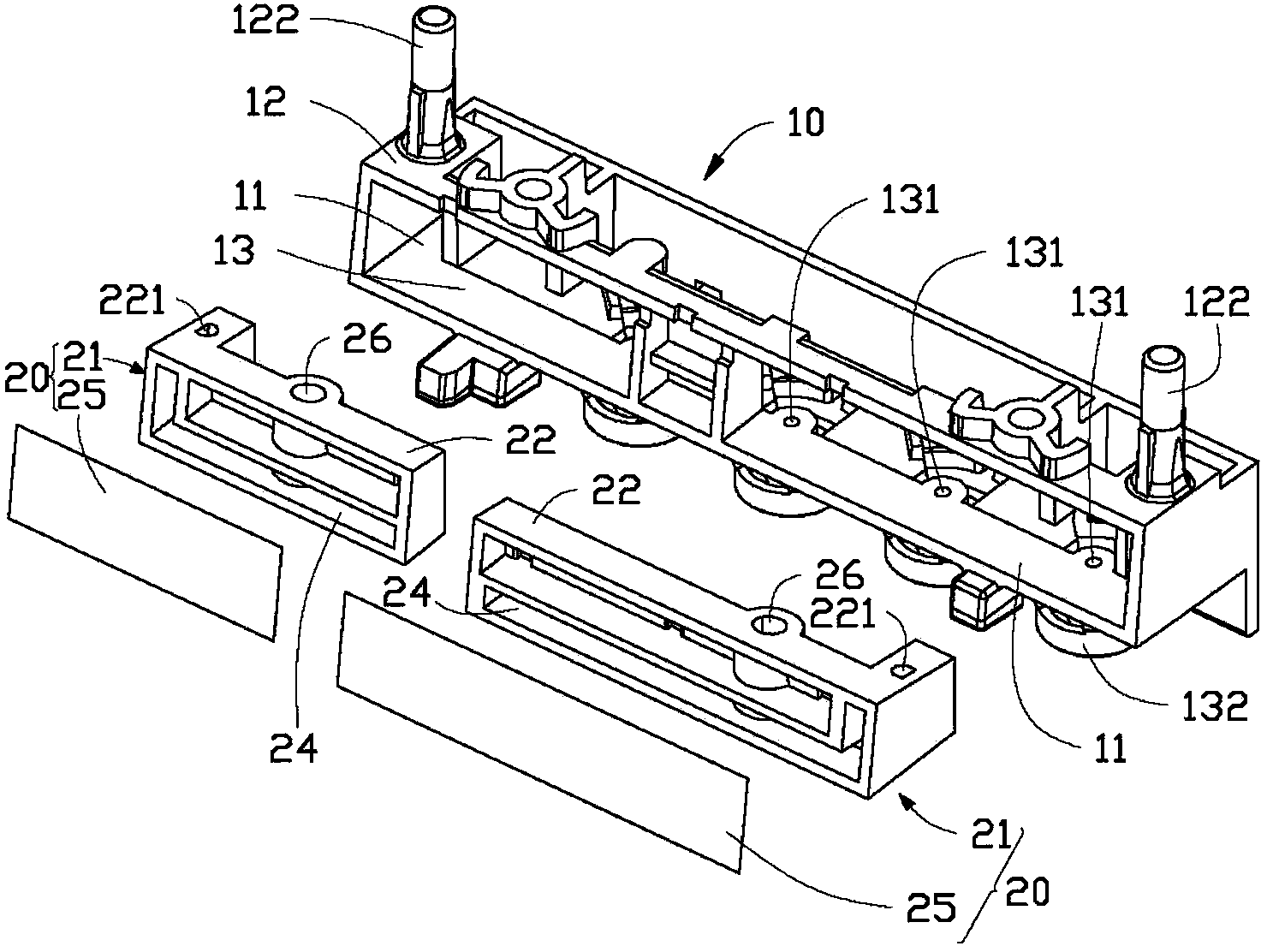

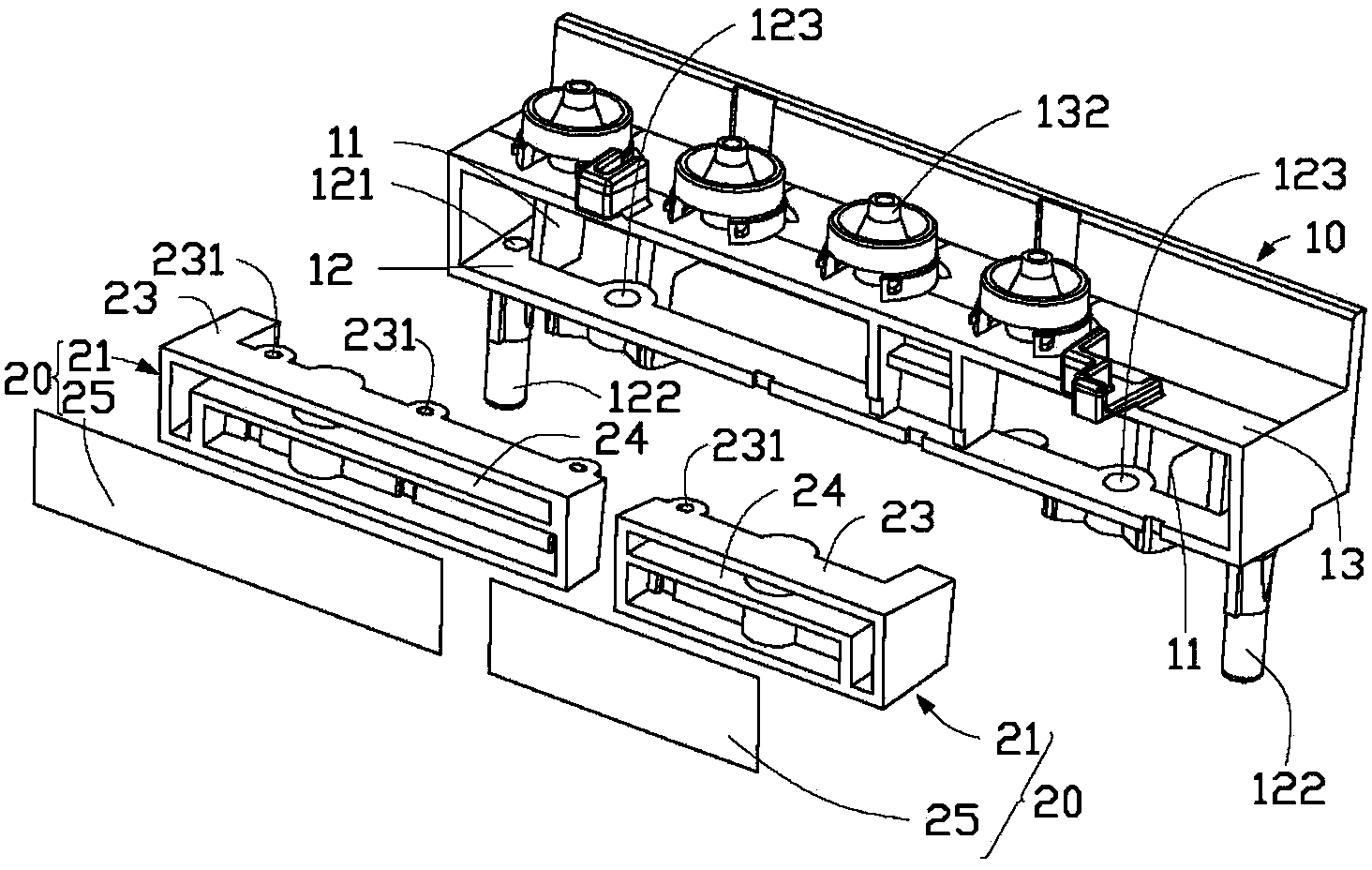

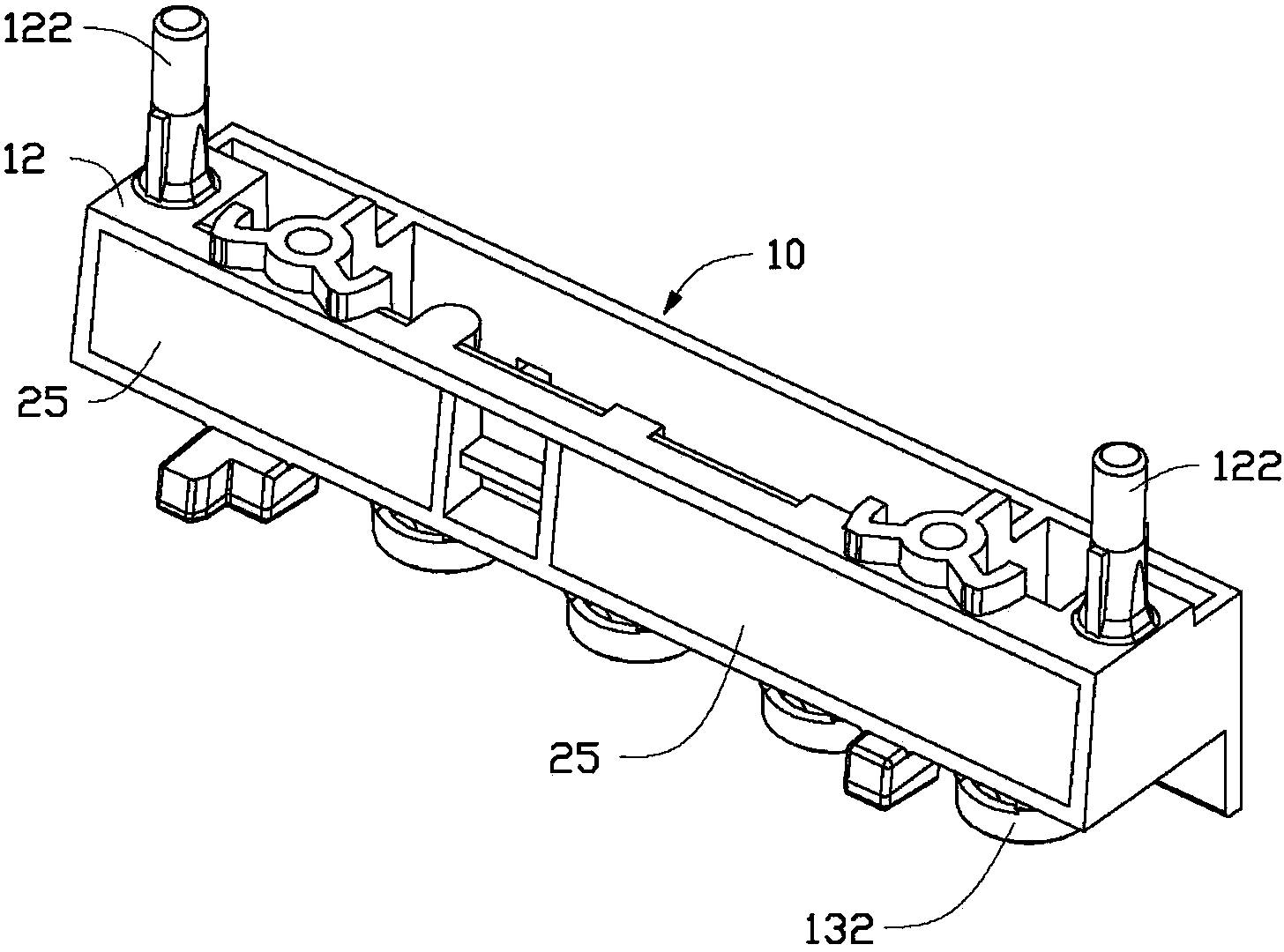

[0020] see Figure 1 to Figure 3 , In a preferred embodiment of the present invention, a replaceable air chamber mechanism used in an ink supply system of an inkjet printer includes a fixer 10 and at least one movable part 20 . The holder 10 is provided with at least one receiving groove 11 for receiving the movable part 20 . In this embodiment, the number of the movable parts 20 is two, one is used to provide the air chamber for connecting the color ink cartridges (not shown in the figure), and one is used to provide the air chamber for connecting the black and white ink cartridges (not shown in the figure). ) of the air chamber. Those skilled in the art should understand that the number of the movable elements 20 can be increased or decreased as required. Correspondingly, the number of the accommodating grooves 11 can also be increased or decreased as required.

[0021] The holder 10 includes an upper wall 12 and a lower wall 13 . The upper wall 12 defines an air inlet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com