Automatic extruding and compressing equipment for plastic product

A technology for compressing equipment and products, applied in the field of mold manufacturing, can solve problems such as size reduction, and achieve the effect of simplifying workload and improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

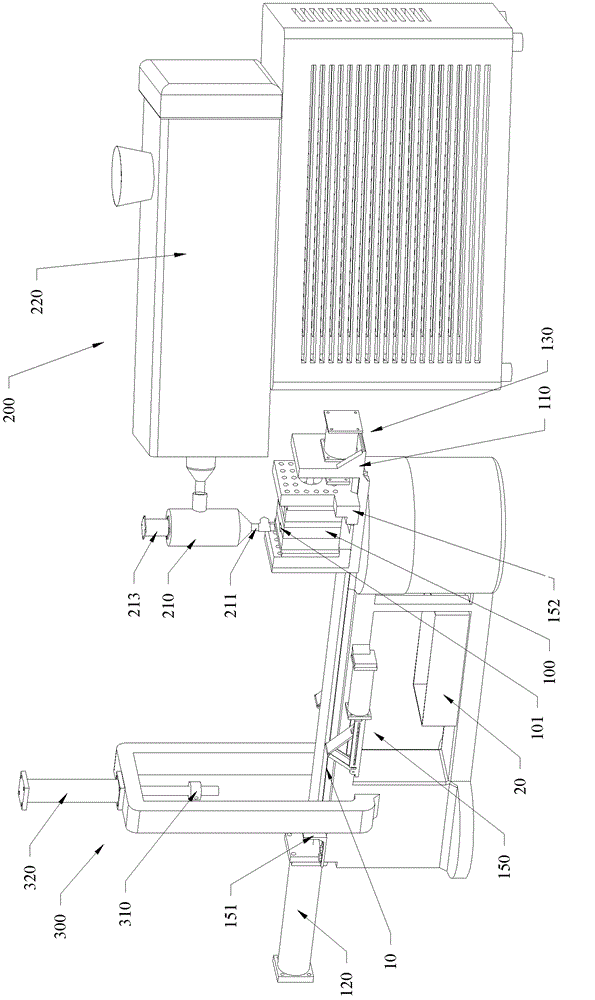

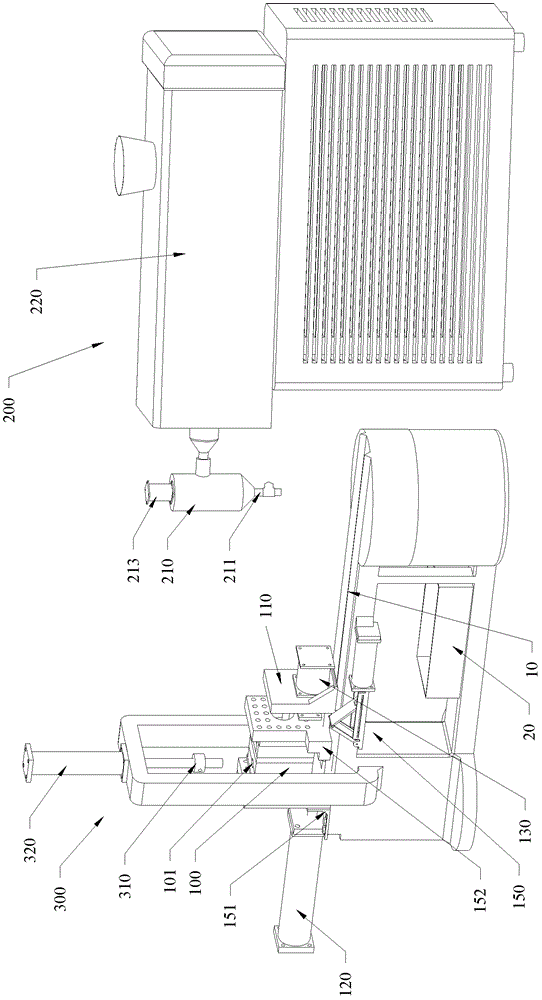

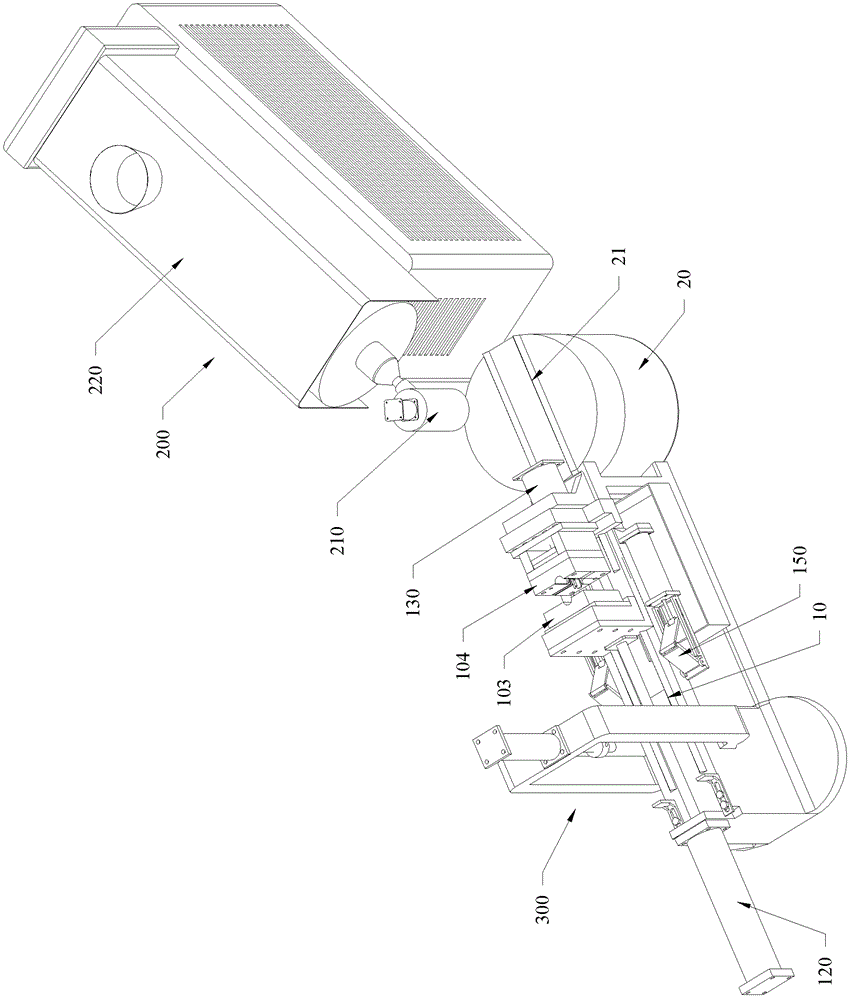

[0026] Such as figure 1 , 2 , 3, in the preferred embodiment of the automatic extrusion compression equipment for plastic products of the present invention, it includes a mold 100 with a stacking cavity 101, an extrusion device 200 for injecting fillers into the stacking cavity 101, and the stacking The filling in the cavity 101 is compressed into the mold cavity 102 and the compression device 300 continuously pressurizes the stacking cavity 101 during the cooling process of the mold. The stacking cavity 101 communicates with the mold cavity 102, and the volume of the stacking cavity 101 is larger than Mold cavity 102 volume.

[0027] Wherein, the compression device 300 includes a pressing head 310 and a pressing driving mechanism 320 , and the pressing head 310 can cover the material stacking cavity 101 of the mold and seal the material stacking cavity 101 . Specifically, the pressing driving mechanism 320 can be set as a hydraulic cylinder, the pressing head 310 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com