Claw type unscrewing cap with safety button structure

A safety button and unscrew cap technology, which is applied in capping, bottle/container caps, and capping containers with caps, etc., can solve the problems of low market adoption rate, large vacuum suction value, and small vacuum suction value, and achieve Improve the plastic deformation range, reduce the vacuum suction value, and reduce the effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

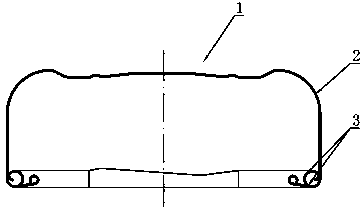

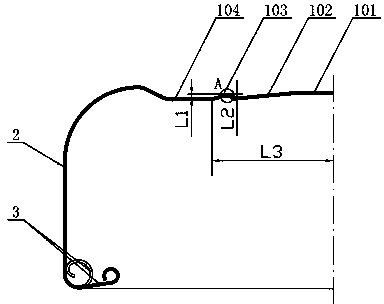

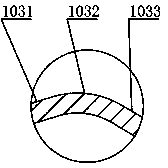

[0017] Such as figure 1 , figure 2 As shown, as shown, the present invention includes a cover top 1, a cover wall 2 and a cover claw 3 connected to each other. The middle part of the cover top 1 is a horizontal part 101, and the two ends of the horizontal part 101 extend downward along the horizontal line to form an inclined part. 102 , the end of the inclined portion 102 is extended to form a bent portion 103 and connected to one end of the connecting portion 104 , and the other end of the connecting portion 104 is connected to the cover wall 2 . The curved part 103 is connected to form a "V" shape by connecting the first straight line segment 1031, the second straight line segment 1033 and the arc segment 1032. By setting the curved part 103, the elastic deformation range is increased, and the plastic deformation is reduced. probabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com