Lift car structure

A technology for elevator car and car, which is applied to elevators, lifts, transportation and packaging in buildings, etc., can solve the problems of high drop of elevator car, no transitional multi-level buffer setting, and wire rope is prone to breakage, etc. achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

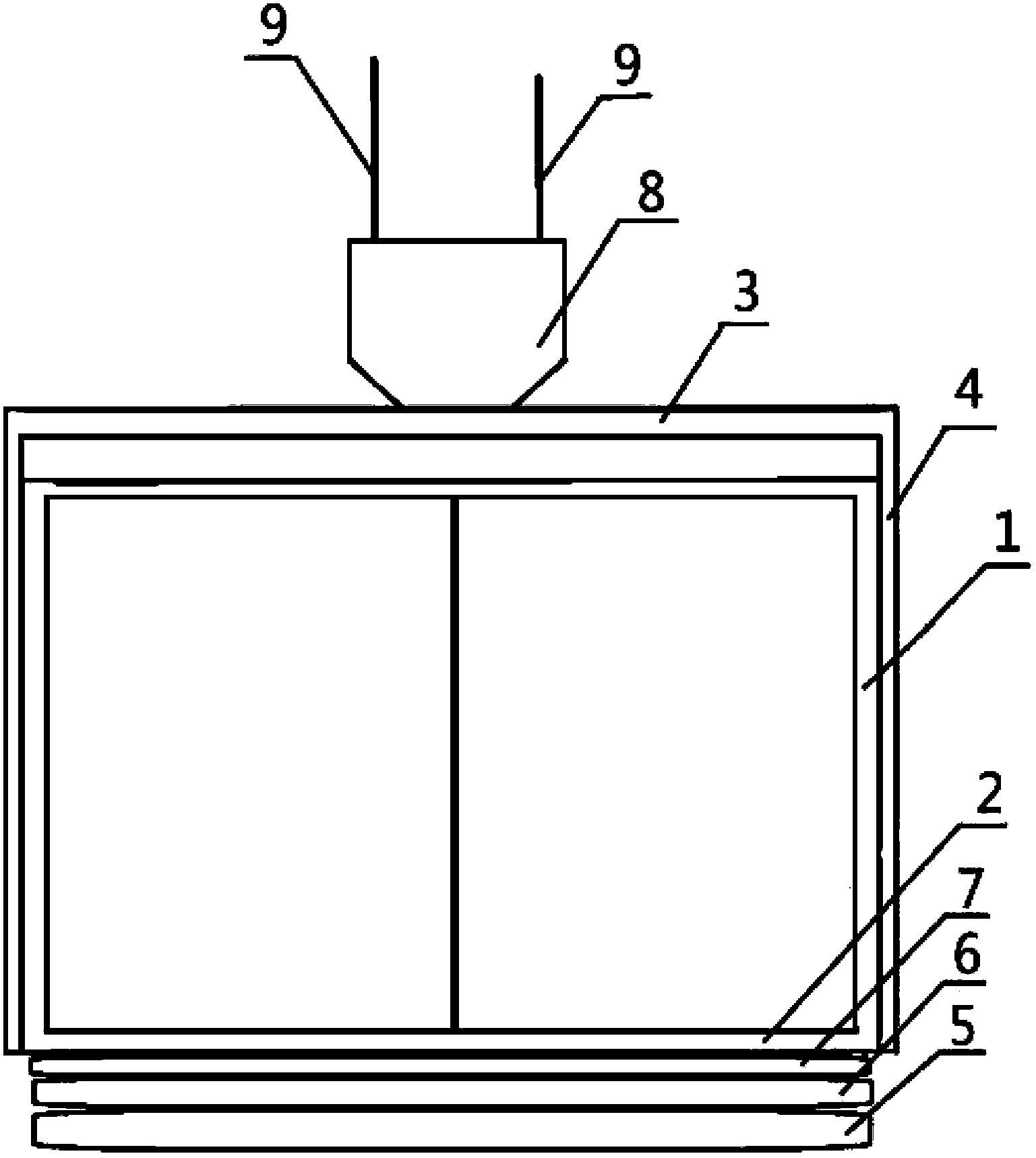

[0008] The elevator car structure has an elevator car (1) and a car base (2), and a large air bag (5), a middle air bag (6) and a small air bag (7) are sequentially installed on the lower part of the car base (2). A car straight beam (4) is installed on the elevator car (1), a car upper beam (3) is installed on the top of the car straight beam (4), and a car Top pulley (8), wire rope (9) are hinged together with car top beam (3) by car top pulley (8).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com