Cross yarn looped pile structure knitted fabric and processing method thereof

A technology for knitted fabrics and processing methods, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of difficult processing methods, large loop spans, long looping lines, etc., and achieve large loop structure spans. , low hairiness, long looping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Process the cross-thread terry structure knitted fabric according to the following weaving process:

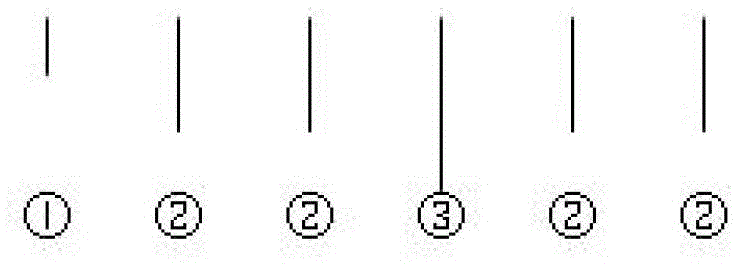

[0020] The terry structure part is made of 10S 100% polyester yarn with a single fiber length of more than 7cm, and the bottom plain structure part is made of 150D / 72F DTY polyester low elastic yarn. ) on knitting, knitting needle press figure 1 Arrangement shown in the arrangement method, there are three knitting needles, and the knitting needles are arranged in a cycle of six needles, that is, the knitting needles are 1 needle for the 1st lane, 2 needles for the 2nd lane, 1 needle for the 3rd lane, and 1 needle for the 2nd lane 2 pieces are arranged in a cycle of six needles, (the first needle and the third needle are respectively used one piece, and the second needle is separated by two pieces, so that the front and rear two needles belong to the first needle cycle in the front and rear needle cycles. 5 needles apart from other needles; similarly, 2 needles before a...

Embodiment 2

[0028] Process the cross-thread terry structure knitted fabric according to the following weaving process:

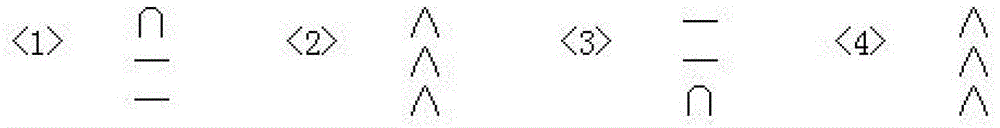

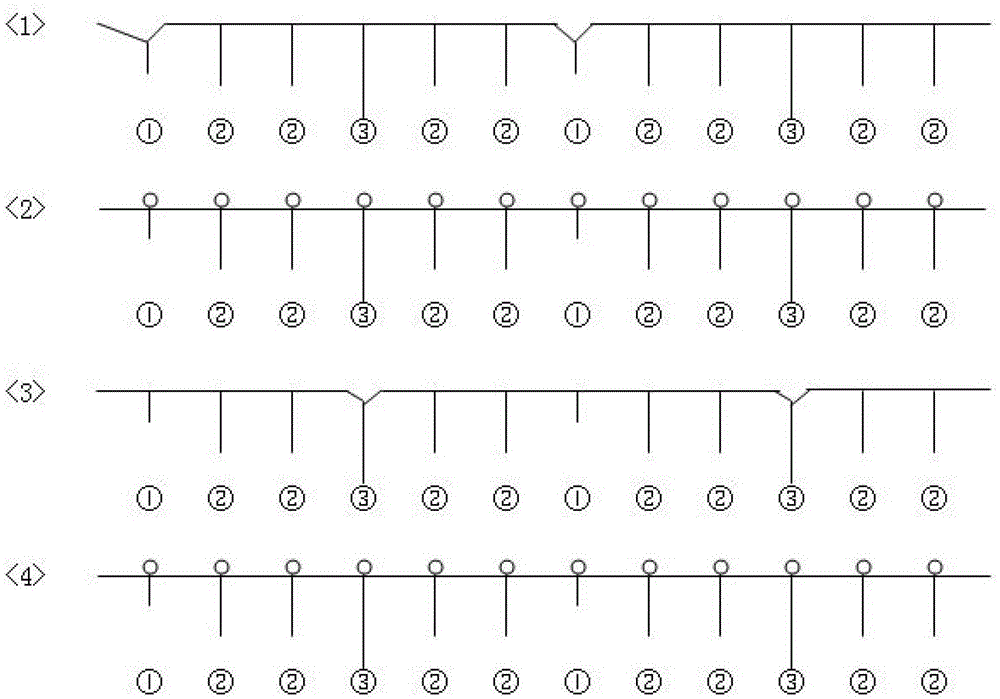

[0029] The terry structure part is made of 16S 100% polyester yarn with a single fiber length of more than 7cm, and the bottom plain structure part is made of 32S cotton yarn. It is knitted on a single-jersey circular knitting machine (30 inches, 28 needles and 96 channels). figure 1 Arrangement shown in the arrangement method, there are three knitting needles, the knitting needles are arranged according to the first needle 1, the second needle 2, the third needle 1, and the second needle 2 such that six needles are arranged in a cycle; triangle according to figure 2 Arranged according to the triangular arrangement method shown; image 3 The weaving diagram shown is for weaving. The weaving process is four-way and one-cycle. Among them, 16S 100% polyester yarn is worn in the 1st and 3rd way to weave a terry structure; 32S cotton yarn is worn in the 2nd and 4th way, an...

Embodiment 3

[0037] Process the cross-thread terry structure knitted fabric according to the following weaving process:

[0038] The terry structure part is made of 10S 100% polyester yarn with a single fiber length of more than 7cm, and the bottom plain structure part is made of 32s T / C 60 / 40. upper knitting, knitting needles press figure 1 Arrangement shown in the arrangement method, there are three knitting needles, the knitting needles are arranged according to the first needle 1, the second needle 2, the third needle 1, and the second needle 2 such that six needles are arranged in a cycle; triangle according to figure 2 Arranged according to the triangular arrangement method shown; image 3 The weaving diagram shown is for weaving. The weaving process is four-way and one-cycle. Among them, 10S 100% polyester yarn is worn in the 1st and 3rd way to weave a terry structure; ; The specific weaving process is as follows:

[0039] In the first pass, use 10S 100% polyester yarn to do tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com