Box girder vertical bending moment test mechanism

A vertical bending moment, box beam technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problem of inability to accurately collect data, and achieve easy acquisition, novel structure, and structural span. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in more detail below in conjunction with accompanying drawing example:

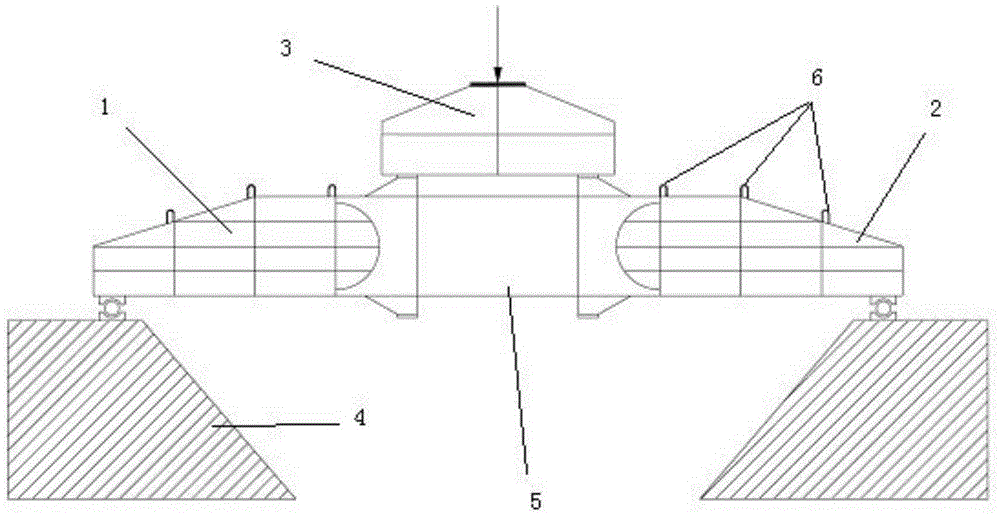

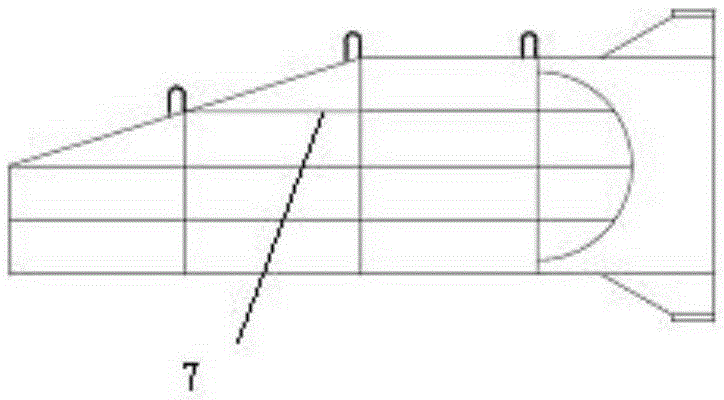

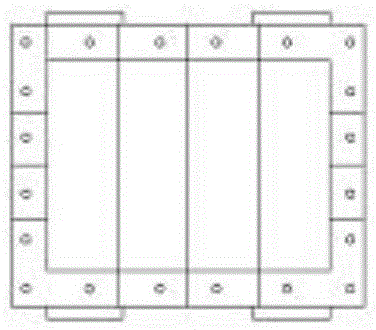

[0016] combine Figure 1~4 ,exist figure 1 In , the schematic diagram shows the box beam vertical bending moment test mechanism. The left connecting bridge 1 and the right connecting bridge 2 are connected together with the model test section 5 by bolts, and the whole structure is placed on the support base 4 . The loading mechanism 3 is placed on the model test section, and the upper end faces of the left connecting bridge 1 and the right connecting bridge 2 are installed with lifting lugs 6 . In the three views of the connecting bridge structure in Fig. 2, the connecting bridge 1 on the left and the connecting bridge 2 on the right are provided with reinforcing ribs 7. In FIG. 3 , the loading mechanism 3 is placed on the model test section 5 . For the details of simply supported end of the base, see Figure 4 , weld the shaft seat 12 at the tail of the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com