Composite cable holding roof structure

A roof structure and composite technology, applied to roofs, building components, building structures, etc., can solve the problems of low overall rigidity, low natural frequency, and high cost, so as to improve fatigue resistance, avoid stress concentration, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

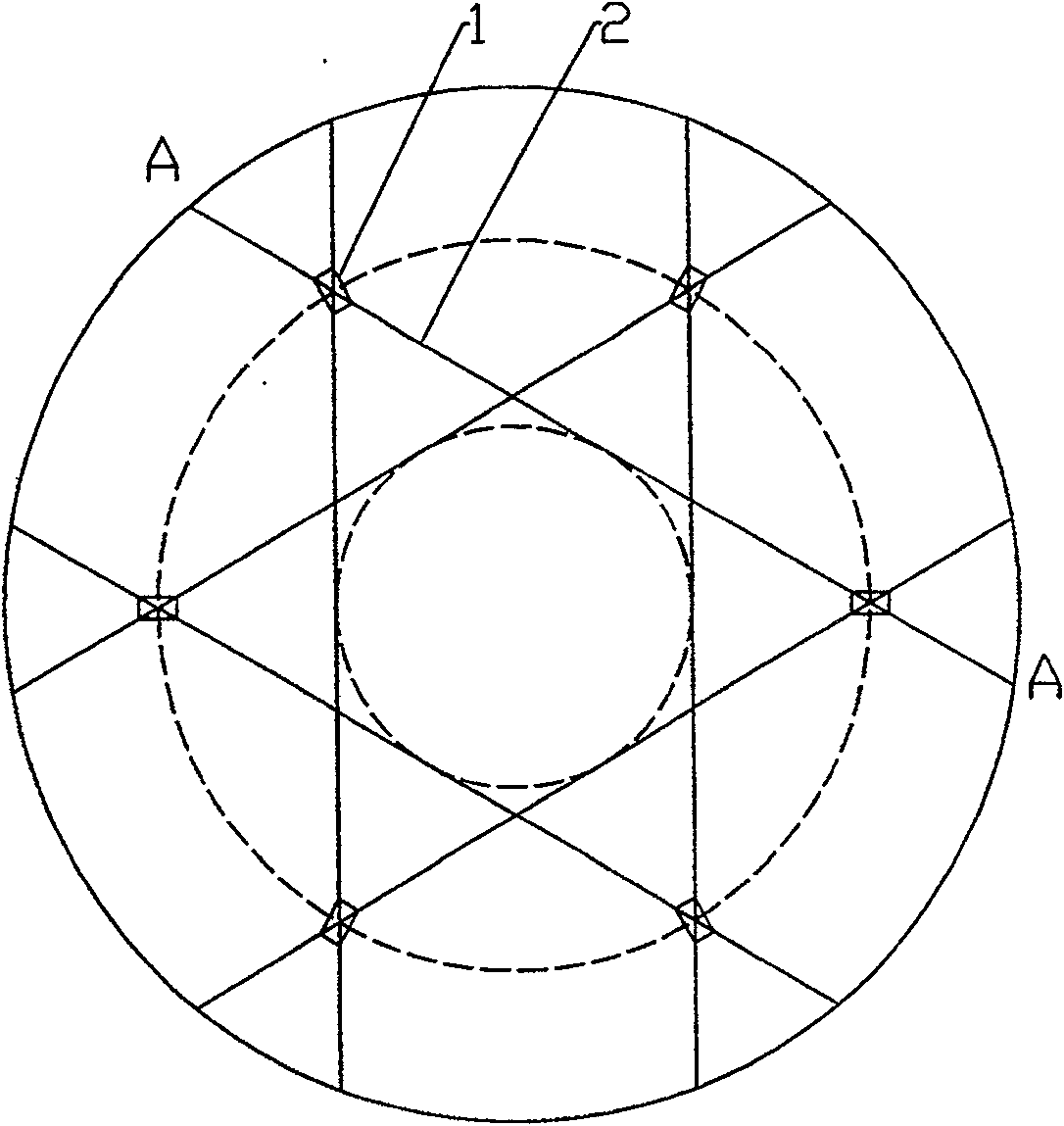

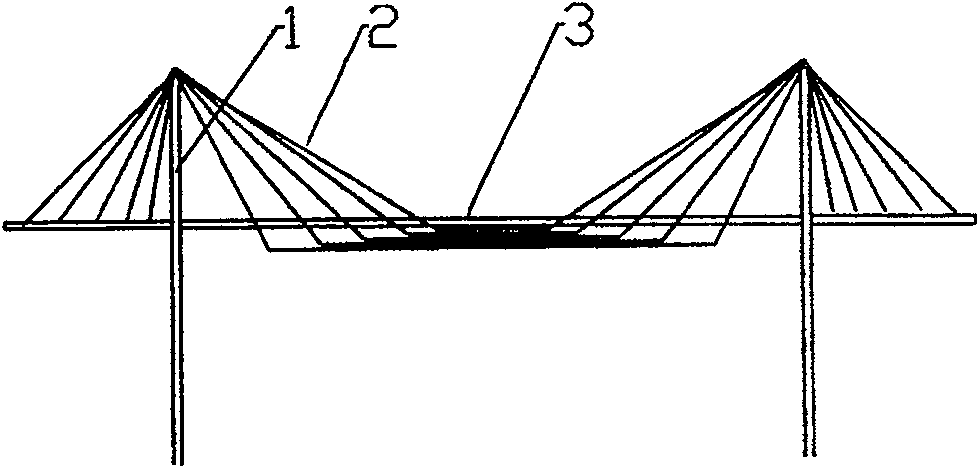

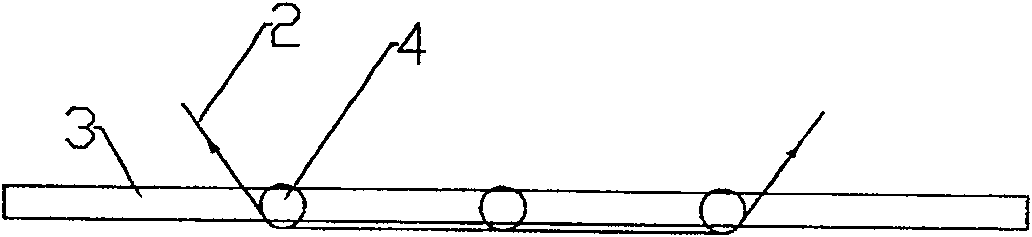

[0024] figure 1 Shown is a schematic diagram of an embodiment of a composite soto roof structure. There are three pairs of main towers 1 in the figure, forming a circular layout, and flexible cables 2 are stretched between each pair of main towers 1 alternately. Cable 2 constitutes a cable net. to combine figure 2 and image 3 As shown, the main girder 4 in the roof structure 3 of the building structure is symmetrically mounted on the flexible cable 2 with the midpoint of the cable 2 as the symmetrical axis, that is, the flexible cable 2 takes the midpoint of the horizontal distance between the two towers 1 as the symmetrical axis from the roof structure. The main girder 4 of 3 passes through, supports the main girder 4, and each flexible cable 2 crosses the cable saddle on the top of the main tower (for the prior art, the cable saddle in the suspension cable structure can be used, omitted in the figure), The two ends are anchored on the anchor head (omitted in the figure)...

Embodiment 2

[0027] like Figure 4 As shown, in this embodiment, 12 main towers 1 form a rectangular layout, and the flexible cables 2 between the main towers form a grid-like cable network to support the main girder of the roof structure from below (omitted in the figure), and the flexible cables Across the cable saddle (omitted in the figure) on the top of the main tower, the two ends of the flexible cable are anchored on the anchor head (omitted in the figure) of the main girder of the roof structure extending out of the main tower 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com