Desulphurization pump impeller of novel structure

A new type of structure, desulfurization pump technology, applied in the components, pumps, pump components of the pumping device for elastic fluid, etc., can solve the problems of difficult assembly and disassembly, poor balance effect, easy damage and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

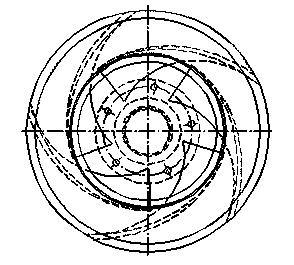

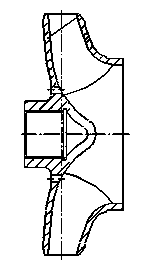

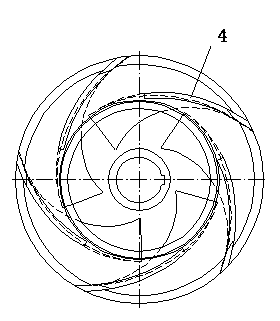

[0007] The figure includes the impeller rear cover, the blades, and the impeller front cover. The blades are installed in the impeller channel formed between the impeller rear cover and the impeller front cover. The front cover auxiliary blades and rear cover auxiliary blades are located on the front and rear sides of the blade respectively. The front cover auxiliary blades The blades and the rear cover plate auxiliary blades extend out of the front cover plate of the impeller and the rear cover plate of the impeller respectively. It is characterized in that the blade, the impeller rear cover plate and the impeller front cover plate are welded and connected to each other. It is characterized in that: the inner hole of the hub of the impeller is a light hole.

[0008] The impeller rear cover and impeller front cover are not easy to damage and can be made of materials with lower requirements. The blades are easy to be damaged and can be made of higher requirements. Road and bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com