Comprehensive environment stress test method of anti-sliding brake control box

A technology of anti-skid braking and comprehensive environment, which is applied in the field of comprehensive environmental stress test, can solve problems such as inability to activate and limit the use of equipment, and achieve the effect of improving research and development efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

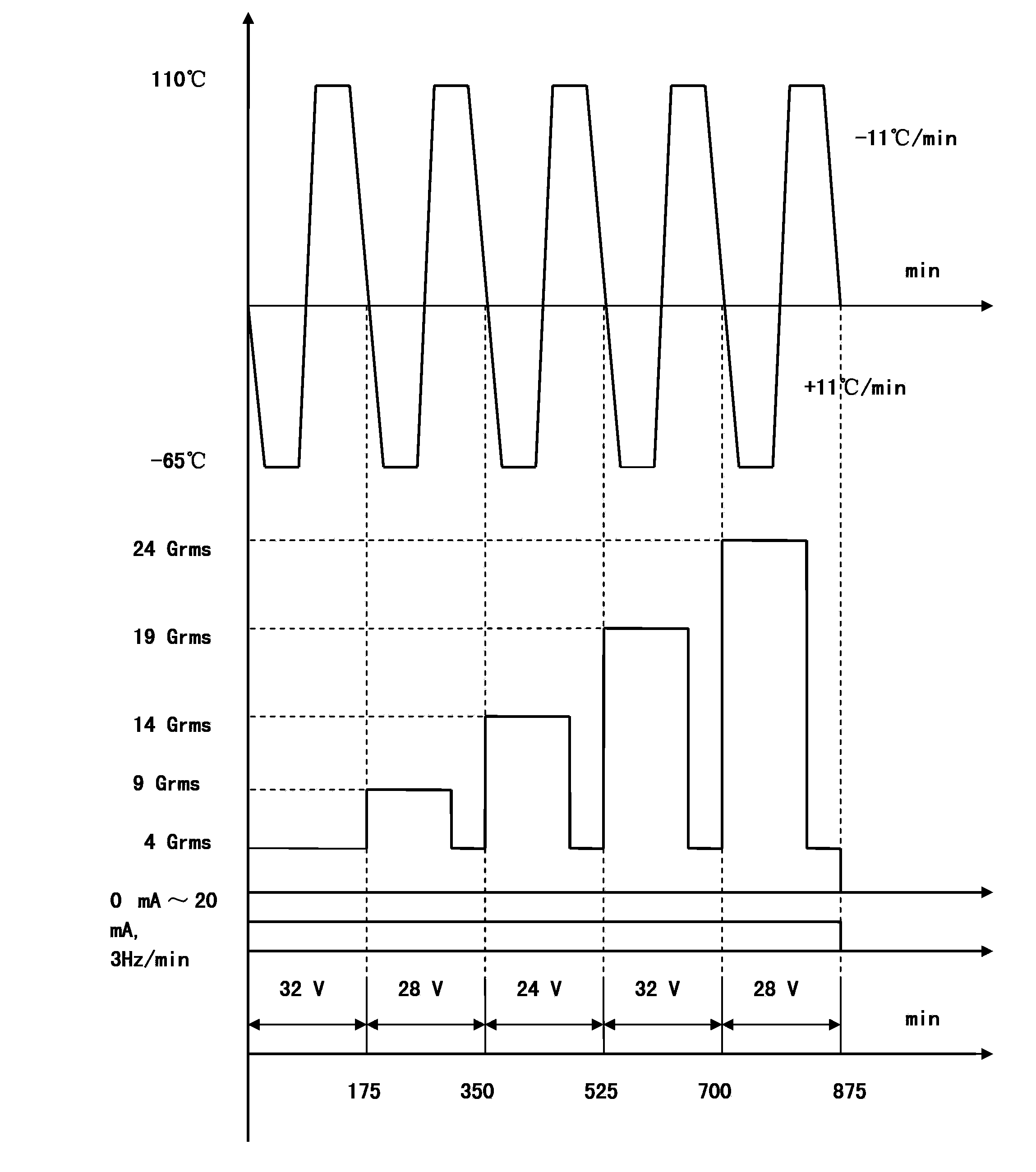

Embodiment 1

[0098] This embodiment is to conduct comprehensive environmental stress and operating current tests on the anti-skid brake control box of the first domestic branch line transport aircraft braking system, and propose technical improvement suggestions for the faults that occurred during the test of this embodiment. The concrete steps of this embodiment are:

[0099] Step 1. Determine the high temperature value of the comprehensive environmental stress test

[0100] When determining the high-temperature value of the comprehensive environmental stress test, first, according to the method disclosed in the invention with the application number 201310169039.1, the method of applying high-temperature stress to test the damage limit under the working state is completed to complete the test process of the high-temperature damage limit of the anti-skid brake control box, and obtain the anti-skid brake The high temperature damage limit of the control box. The high temperature value of th...

Embodiment 2

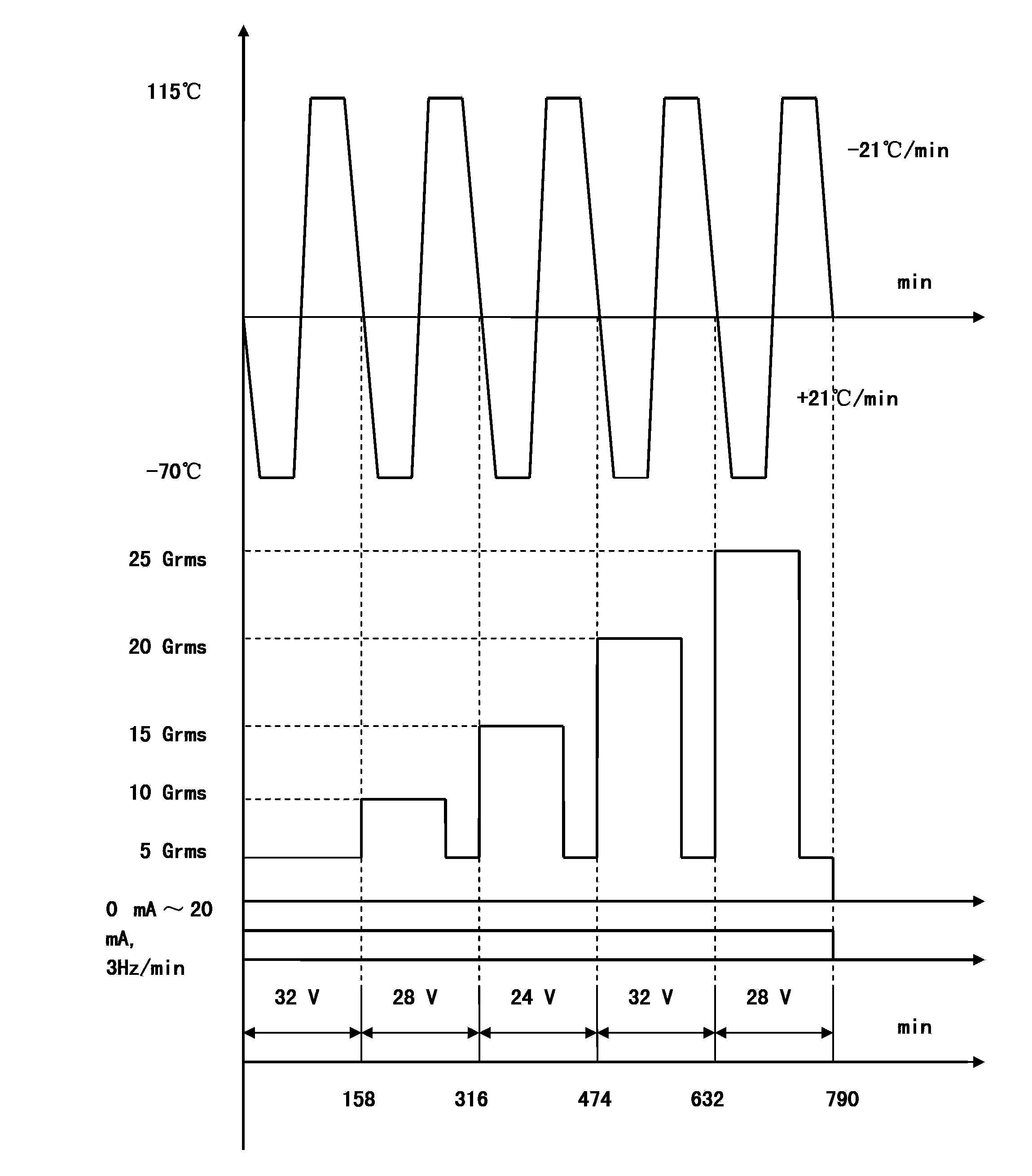

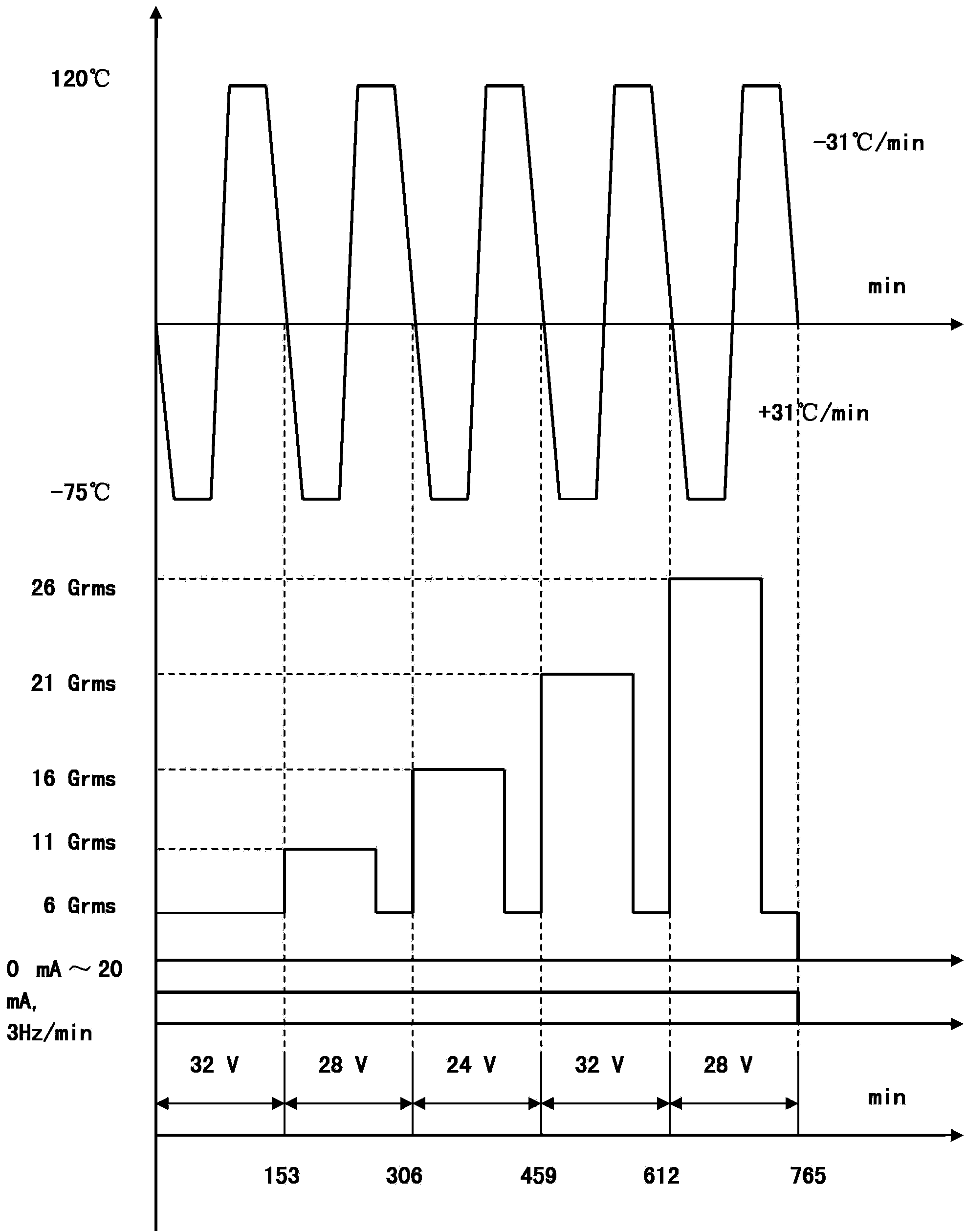

[0151] The processes of embodiment 2 and embodiment 3 all include determining the high and low temperature values of the comprehensive environmental stress test, determining the temperature change rate of the comprehensive environmental stress test, determining the vibration starting point of the comprehensive environmental stress test, and determining the vibration amount of the comprehensive environmental stress test Value increase, determine the micro-vibration value and micro-vibration time of the comprehensive environmental stress test, determine the operating current applied during the test, determine the temperature holding time in the high temperature and low temperature stages of the test, and formulate the test profile of the comprehensive environmental stress. According to the test The comprehensive environmental stress test of the anti-skid brake control box is carried out on the cross-section, and each step of the test verification is carried out to the improved a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com