Patents

Literature

46results about How to "To achieve the purpose of the test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

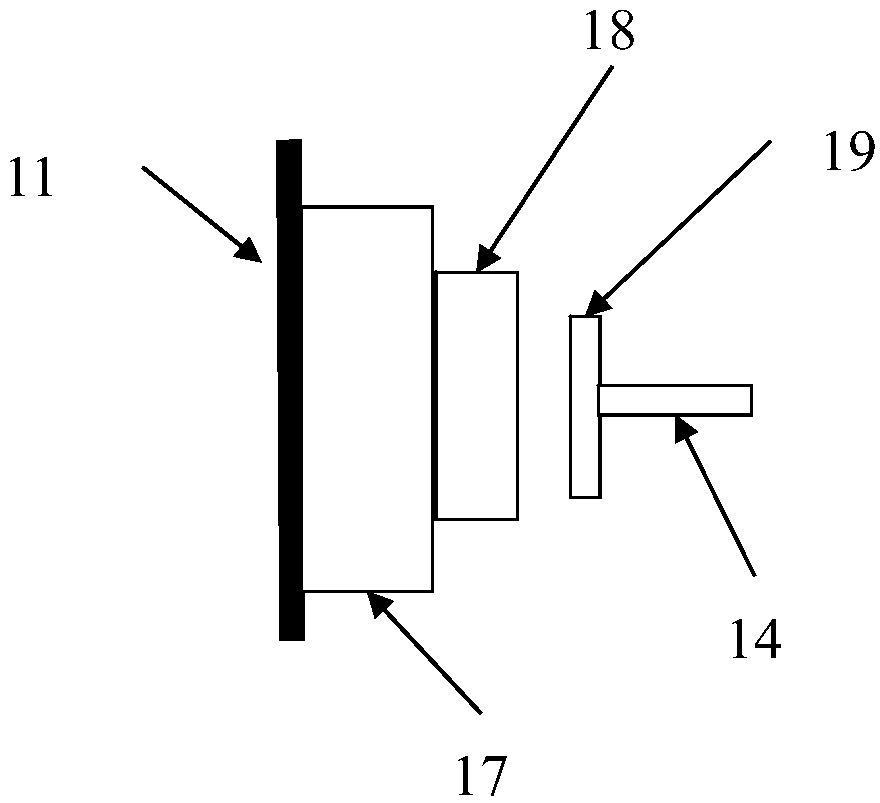

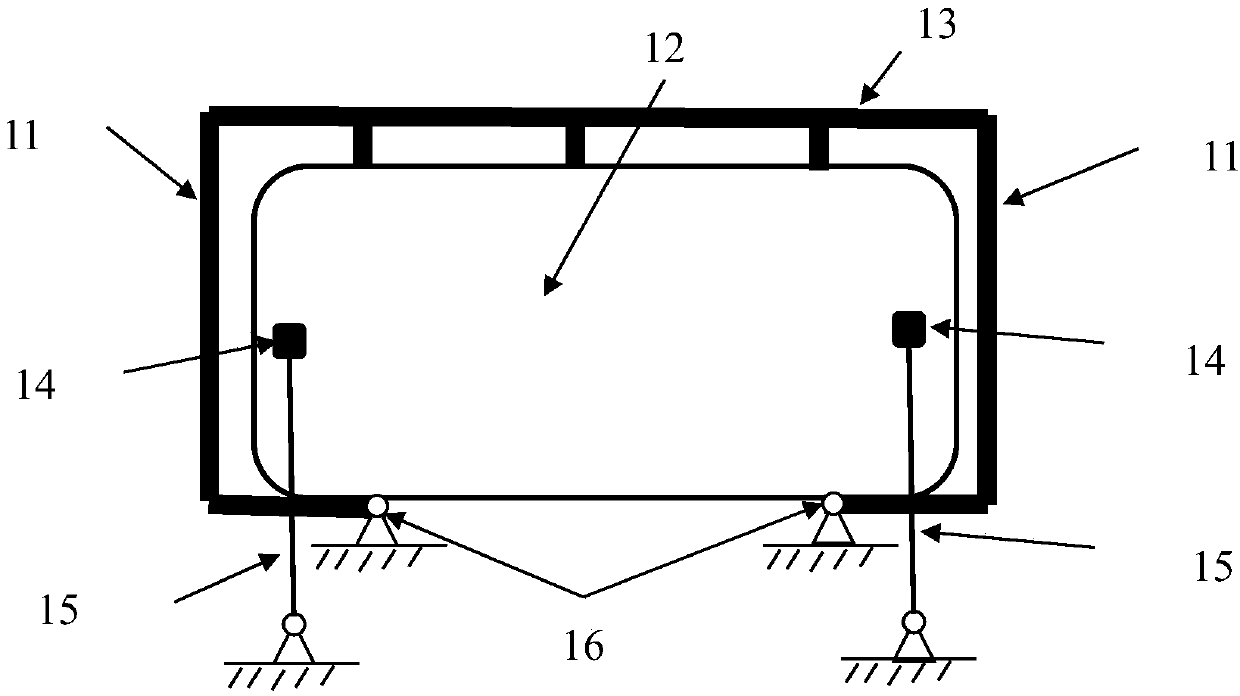

Sectional wave load testing model for air cushion vehicle

InactiveCN103743540AEfficient measurementThe test data is reliableHydrodynamic testingClassical mechanicsMechanics

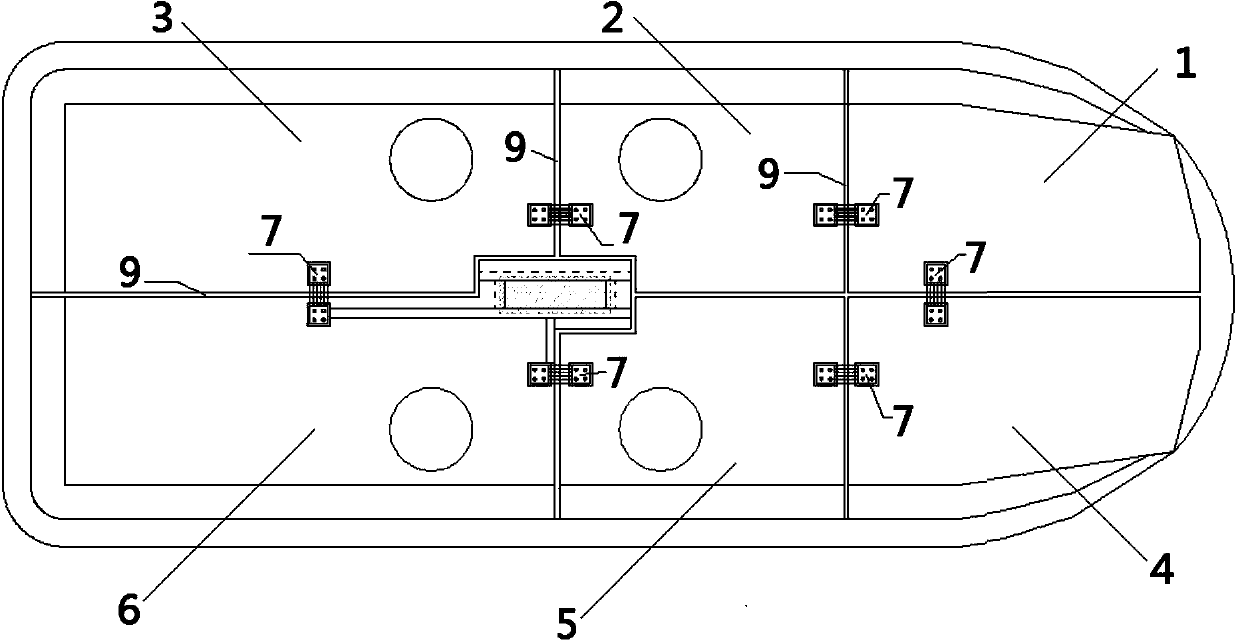

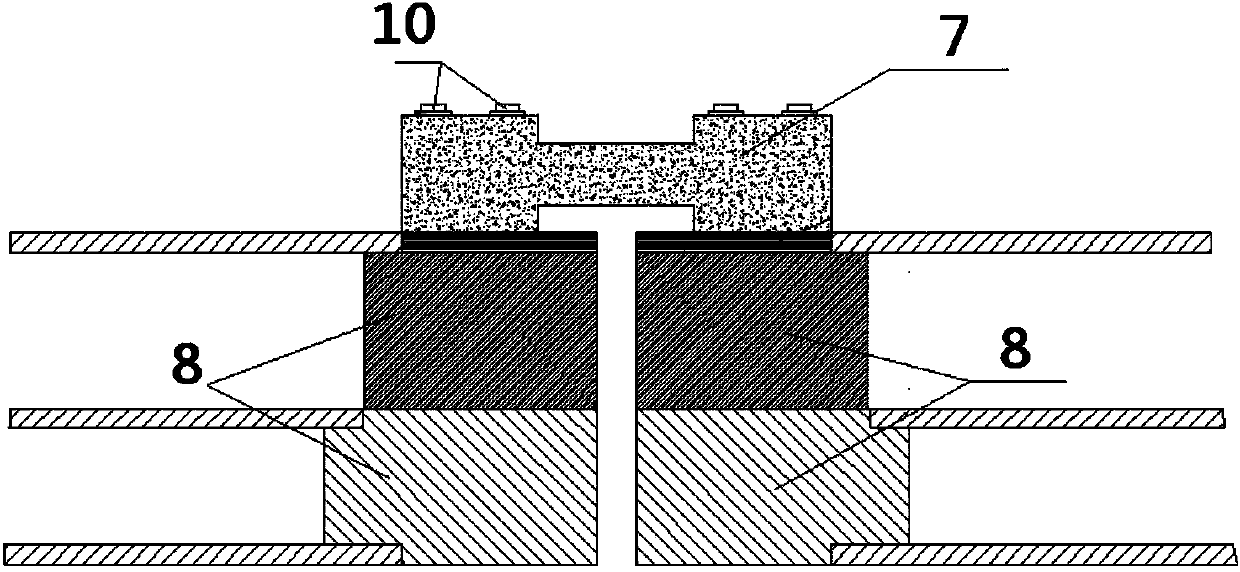

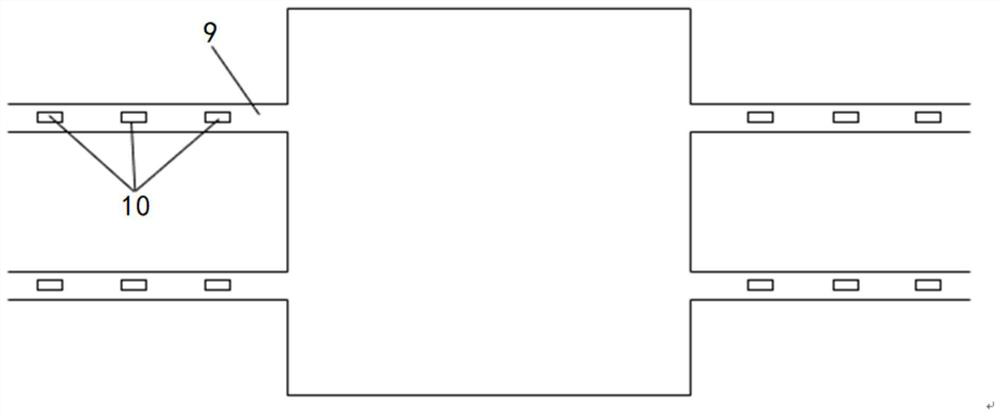

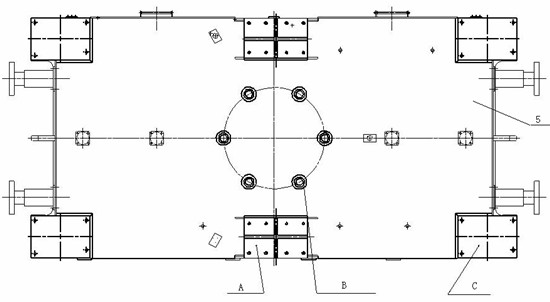

The invention relates to a sectional wave load testing model for an air cushion vehicle. The model comprises an air cushion vehicle model body, and is characterized in that the air cushion vehicle model body has a sectional structure, and consists of six modules, wherein a gap is formed between every two adjacent modules; the modules are fixedly connected through measurement beams.

Owner:HARBIN ENG UNIV

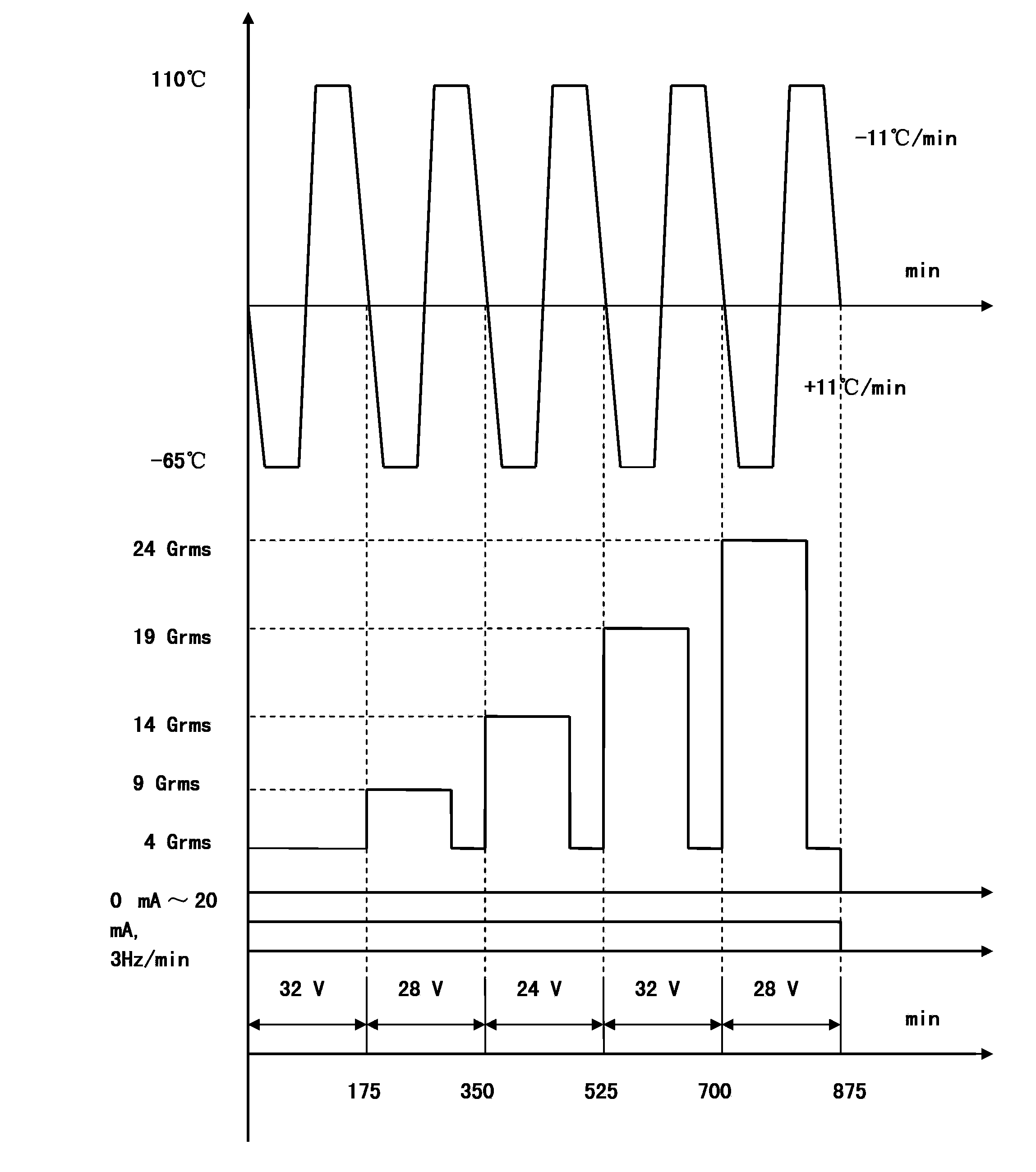

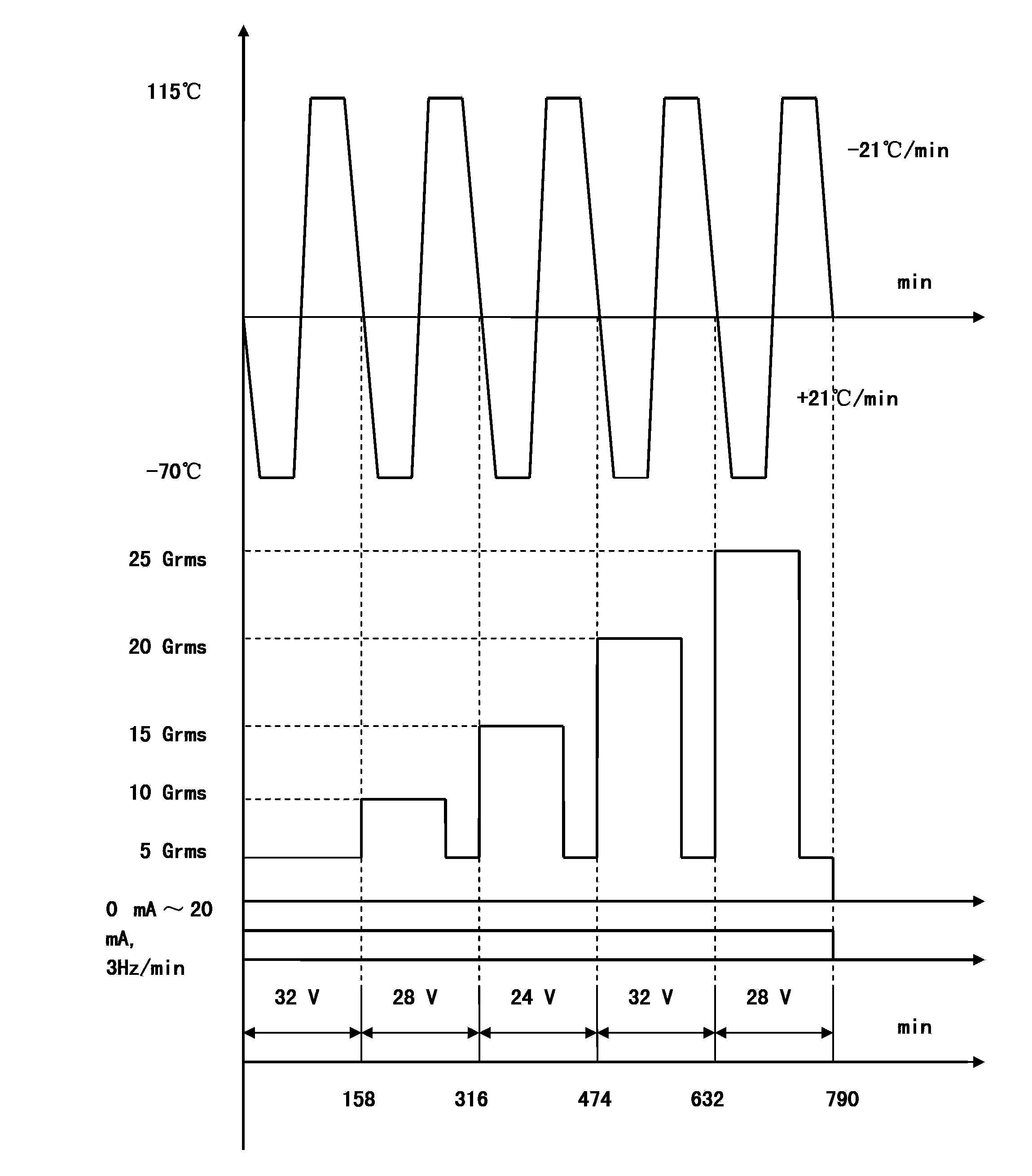

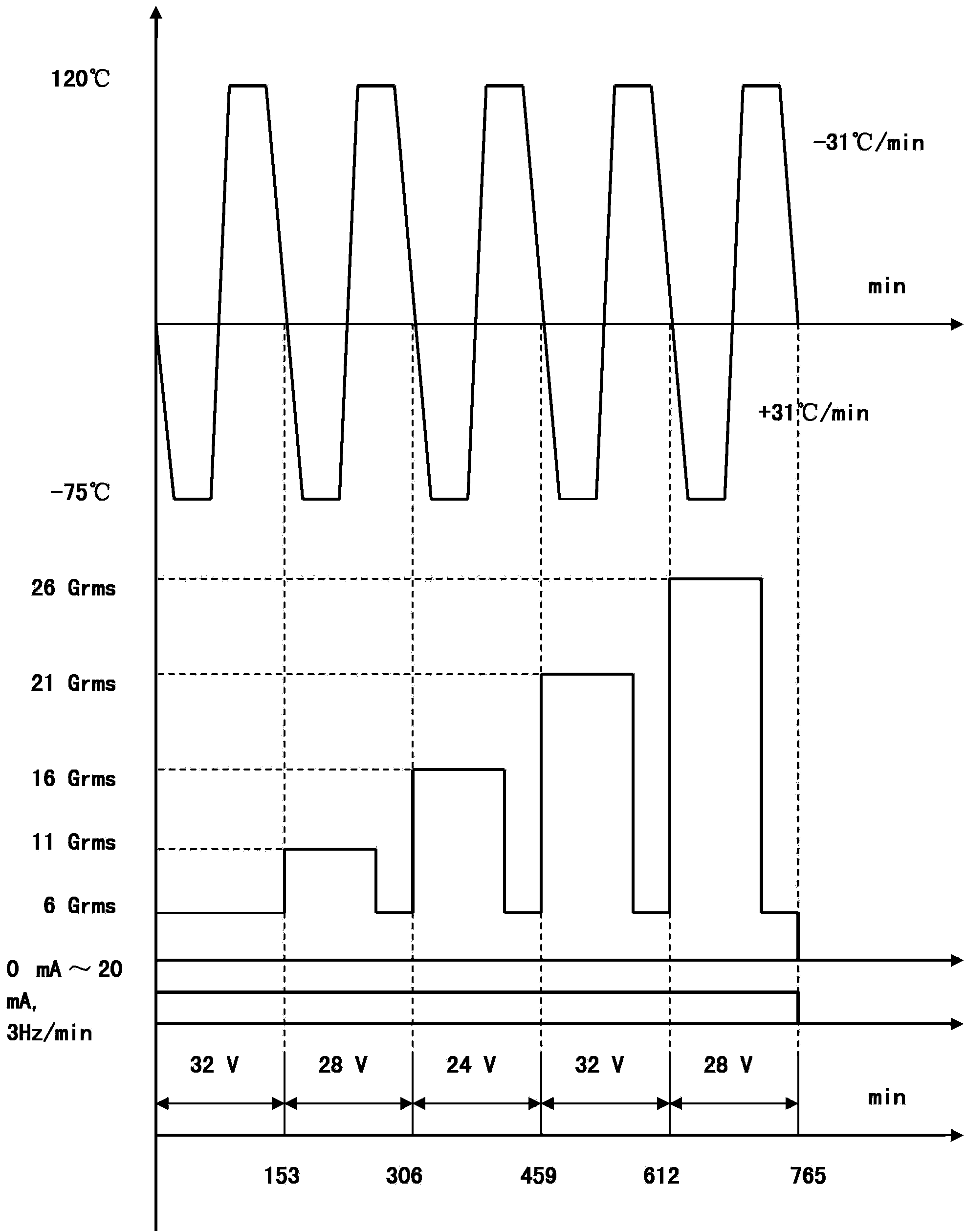

Comprehensive environment stress test method of anti-sliding brake control box

ActiveCN103513647AImprove development efficiencyAbility to work normallyElectric testing/monitoringSoftware engineeringHigh acceleration

The invention relates to a comprehensive environment stress test method of an anti-sliding brake control box. According to comprehensive environment stress and test data, high-temperature stepping test data, low-temperature stepping test data and vibration stepping test data simultaneously exerted by working currents of the anti-sliding brake control box, a high-acceleration stress sieving test profile is made up, a method for carrying out a high-acceleration stress sieving test of the anti-sliding brake control box with three comprehensive test devices is obtained and the function of fully utilizing test data resources is achieved. With the comprehensive environment stress test method, the anti-sliding brake control box is stimulated to be sensitive to potential stoppage risks of the comprehensive environment. Simulating and correcting potential stoppage risks corresponding to the anti-sliding brake control box can be completed in two days and improvement suggestions are provided. In a testing process, an improvement technology is adopted as a development technology of anti-sliding brake control boxes of the type and the development efficiency is improved.

Owner:XIAN AVIATION BRAKE TECH

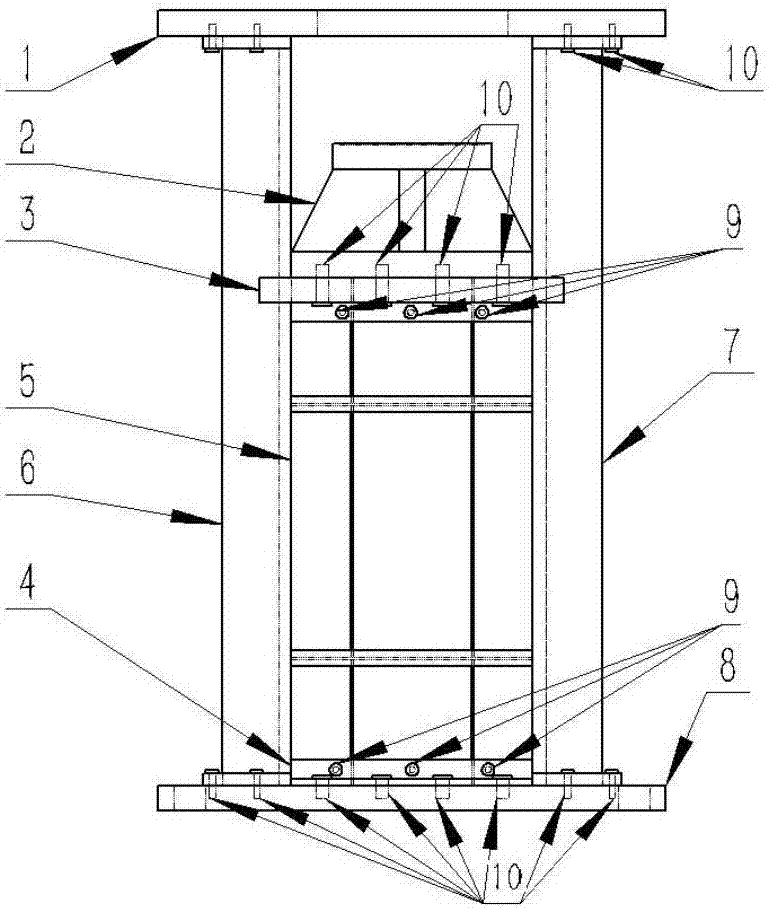

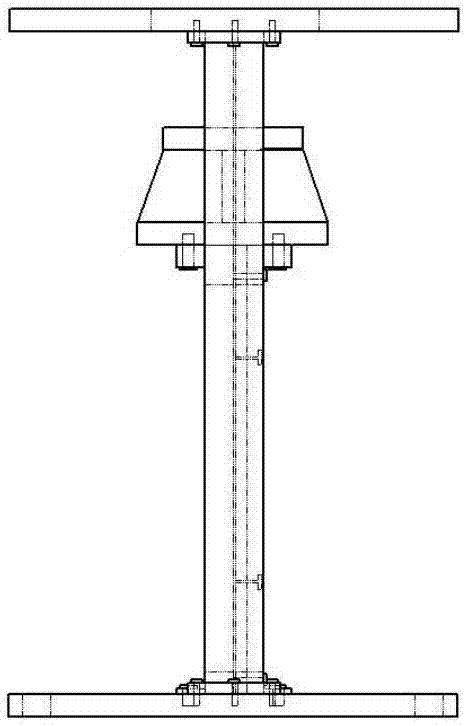

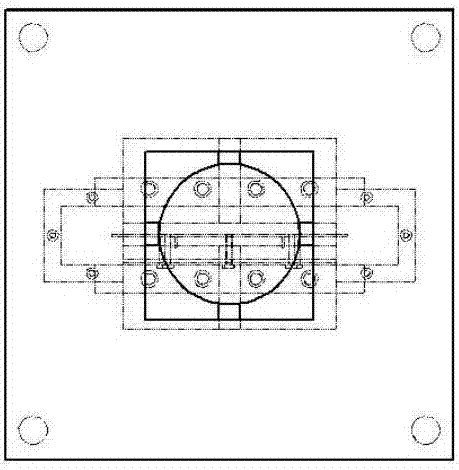

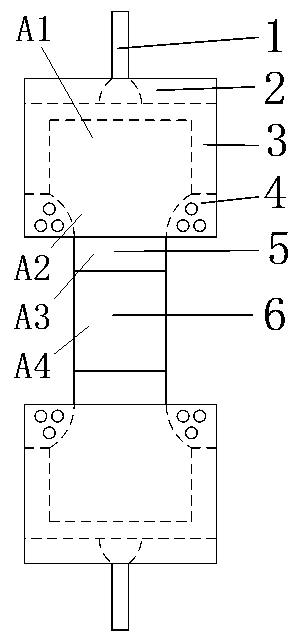

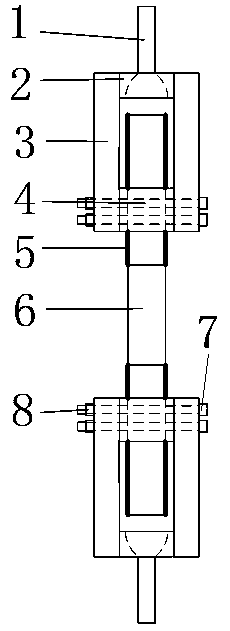

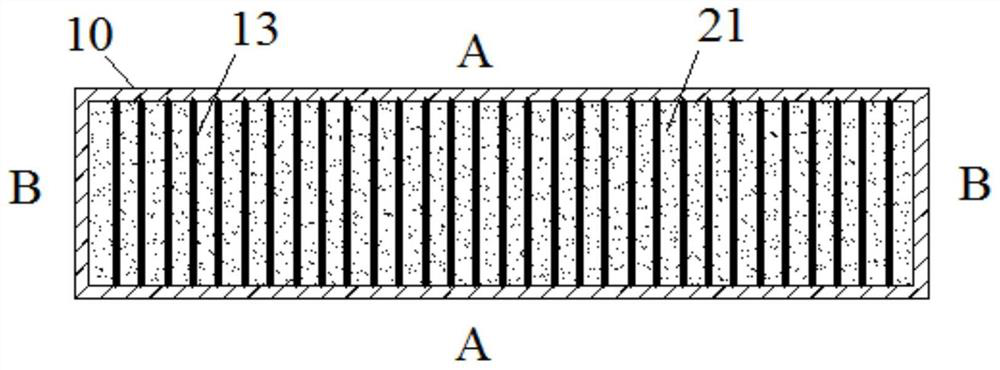

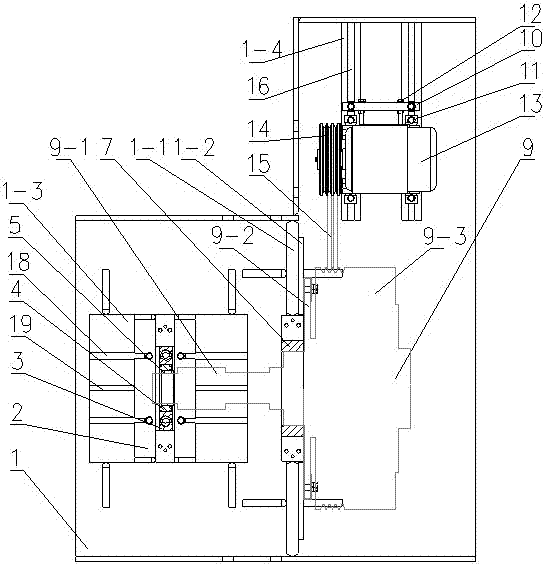

Peripheral reinforcing stiffened plate axial pressure test mechanism

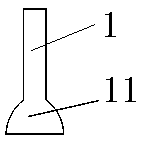

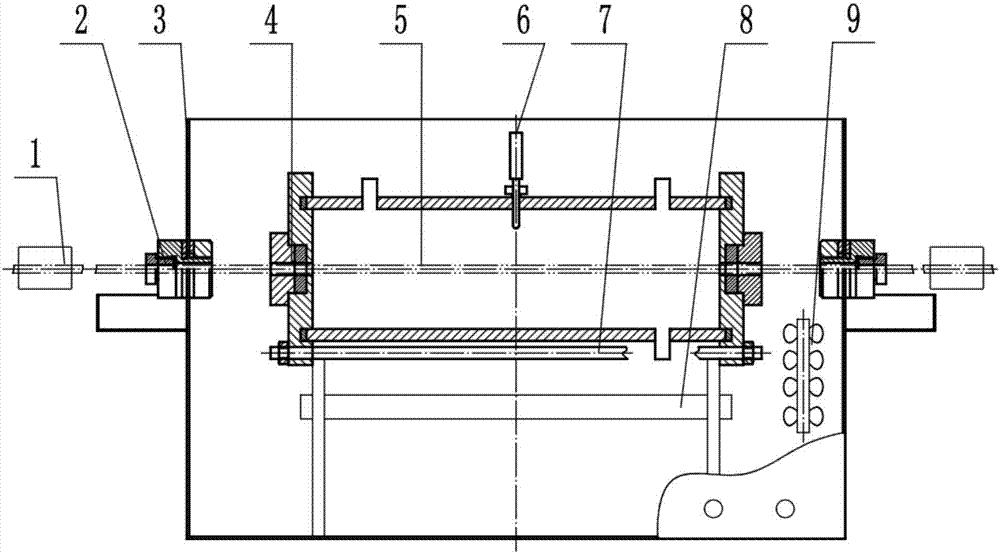

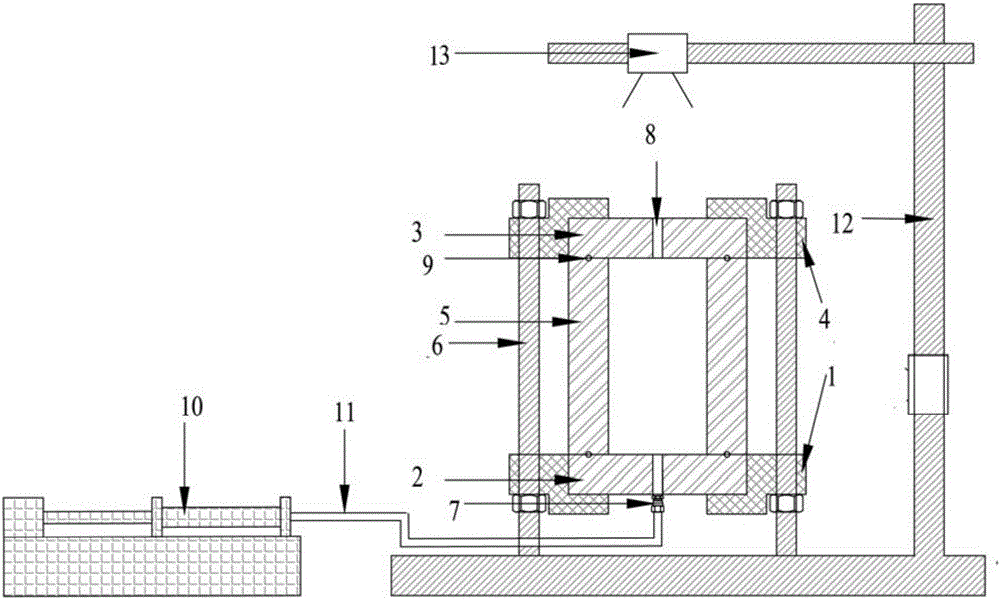

The invention provides a peripheral reinforcing stiffened plate axial pressure test mechanism, which comprises an upper cover plate (1), a loading structure (2), an upper end clamp (3), a lower end clamp (4), a left vertical rail (6), a right vertical rail (7) and a bottom base (8), wherein the lower ends of the lower end clamp (4), the left vertical rail (6) and the right vertical rail (7) are fixed on the bottom base (8); a stiffened plate test piece (5) is clamped between the left vertical rail (6) and the right vertical rail (7); the upper end of the stiffened plate test piece and the upper end clamp (3) are fastened through a fastening screw bolt; the lower end of the stiffened plate test piece and the lower end clamp (4) are fastened through a fastening screw bolt; the upper side of the upper end clamp (3) is connected with the loading structure (2); through the loading structure (2), the load of loading equipment is loaded on the stiffened plate test piece; the upper ends of the left vertical rail (6) and the right vertical rail (7) are connected with the upper cover plate (1). The test mechanism has the advantages that stability and repeated utilization are realized; the experiment goal is realized; meanwhile, the reasonable authenticity of experimental data can also be ensured.

Owner:HARBIN ENG UNIV +1

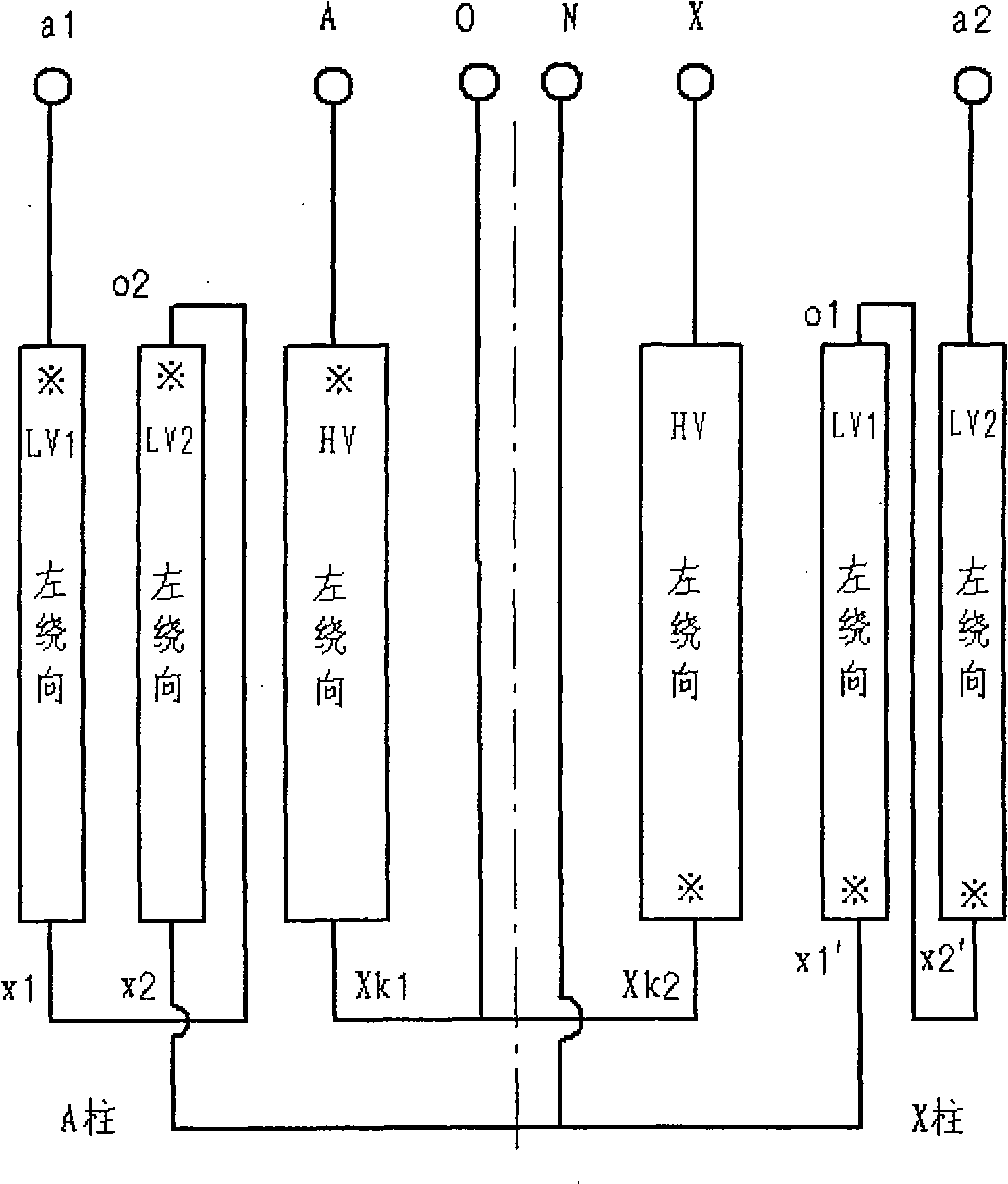

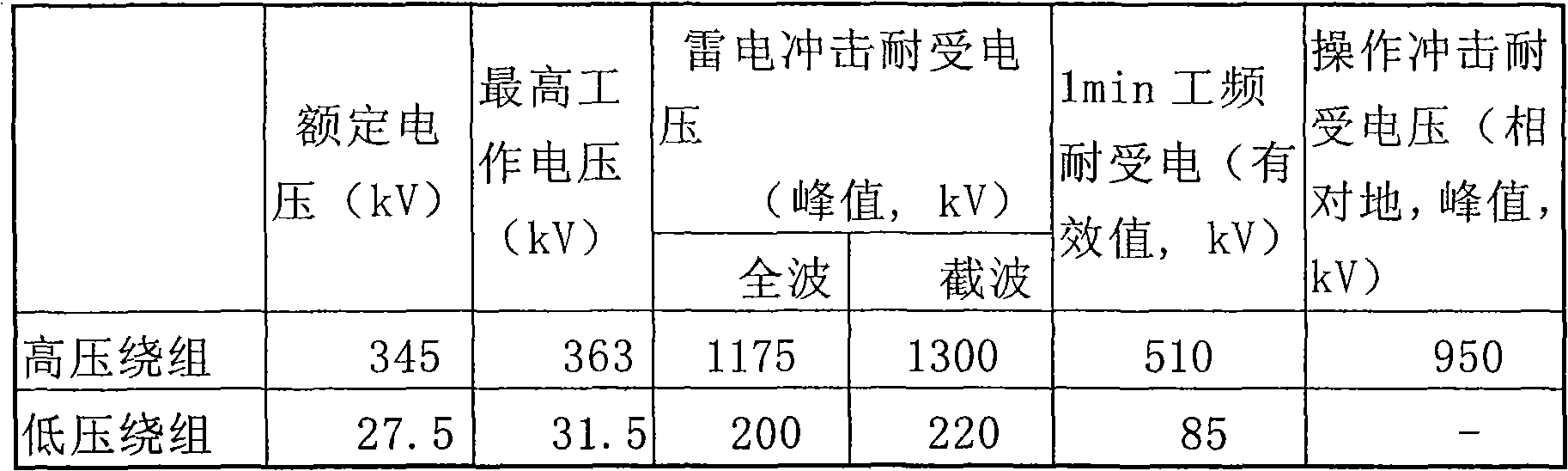

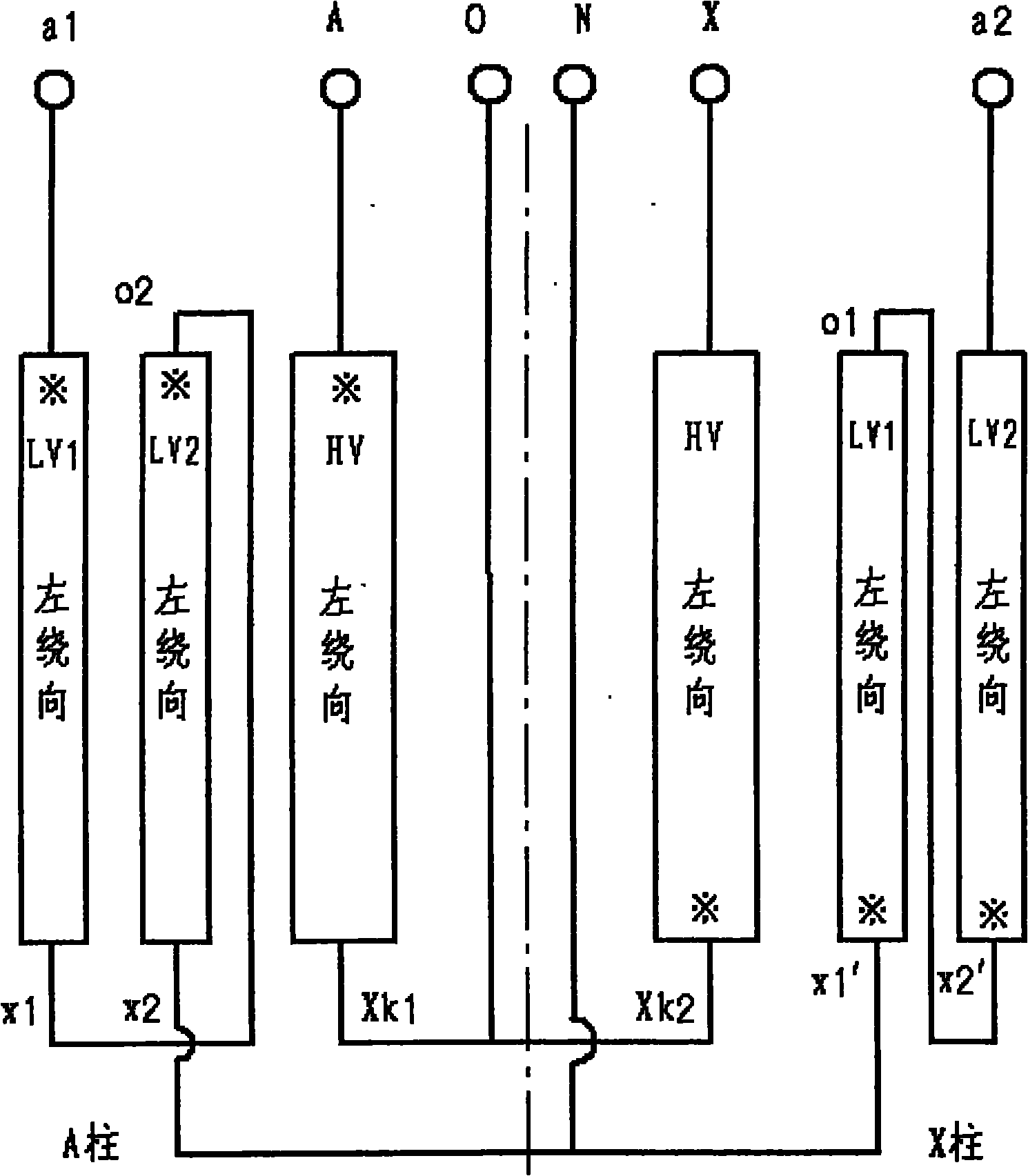

Test method of transformer

ActiveCN101871960ALess investmentHigh utility valueElectrical testingAc/pulses peak value measurementsShort-circuit testLow voltage

The invention discloses a test method of a transformer, which comprises the following steps of: (1) leading out the head ends and the tail ends of two high-voltage windings which are connected in series and are respectively wound on the A pole and the X pole of a single-phase transformer respectively, then tapping at the middle parts of the high-voltage windings and leading out a joint O; (2) leading out the head ends and the tail ends of low-voltage windings which are connected in series and are respectively wound on the A pole and the X pole of the single-phase transformer as a1 and a2 respectively, then tapping at the middle parts of the low-voltage windings, leading out a joint N and grounding the joint N; (3) carrying out short-circuit test on coils on the A / X pole: adding test voltage between the A and the O of a primary side and short-circuiting the joints a1 and N; or, adding the test voltage between the X and the O of the primary side and short-circuiting the joints a2 and N; and (4) measuring the value of the current of the high-voltage windings, which flows through the A / X pole, wherein short-circuit current flowing through the coils of each pole is just an actual short-circuit current peak value. The method can finish the detection of the short-circuit peak current of an extra-high voltage transformer by a test transformer with low voltage class and achieves a test aim.

Owner:TEBIAN ELECTRIC APP CO LTD

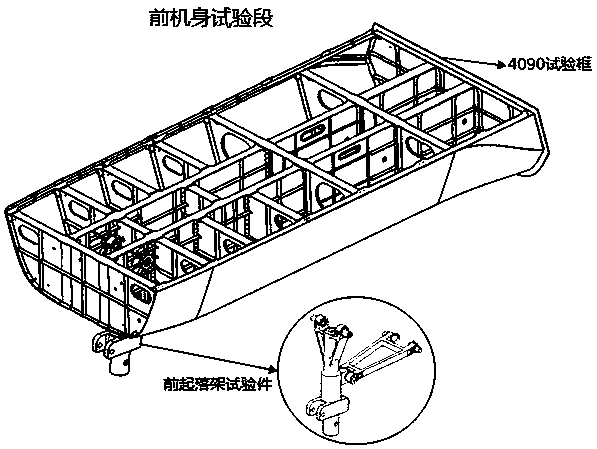

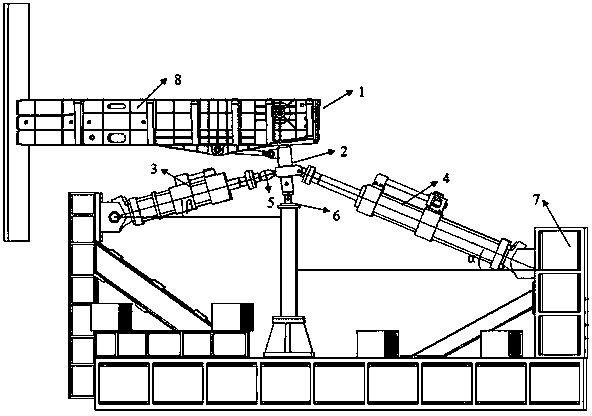

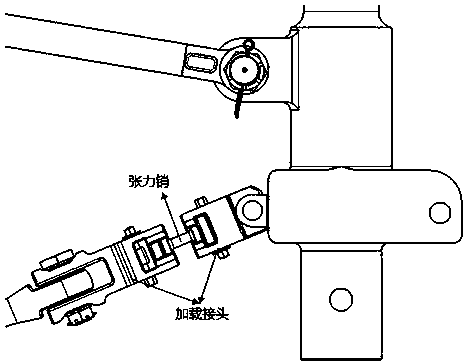

Catapulting impact ground verification test method

InactiveCN108502207ASmall scaleGuaranteed correctnessAircraft components testingJet aeroplaneCatapult

The invention relates to the related field of airplanes, in particular to a ground verification test method for simulating catapult-assisted take-off impact response during catapult-assisted take-offof an airplane. The ground verification test method for simulating the catapult-assisted take-off impact response during the catapult-assisted take-off of the airplane comprises the steps of selectingone section from an airframe structure as a ground verification test piece and an airframe test section according to a main force transmission path of catapult load of a carrier plane; placing overload sensors and bonding strain sensors on the main force transmission paths and key parts of a landing gear and the airframe structure; arranging laser displacement sensors; fixedly restricting the rear end of the test piece on a force bearing wall; and placing a rubber pad at the wheel center of the landing gear to restrict the vertical downward displacement of the test piece in the load applyingprocess. According to the ground verification test method for simulating the catapult-assisted take-off impact response during the catapult-assisted take-off of the airplane, as the main airframe structures on the front landing gear and the main force transmission paths are used as test pieces, the scale of the test pieces is greatly reduced, and the design and manufacturing cost is reduced. Through coordinated loading of multi-passage oil cylinders, the correctness of the load in the whole catapulting process is guaranteed.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

High-strength stainless steel stranded wire mesh enhanced ECC direct tensile test fixture and test method

PendingCN108918256AReduce the cross-sectional areaGuaranteed Axial StretchMaterial strength using tensile/compressive forcesCurve matchingTest fixture

The invention relates to a high-strength stainless steel stranded wire mesh enhanced ECC direct tensile test fixture comprising an upper chuck and a lower chuck, each chuck comprises a chuck body, thechuck body is provided with a curved hole, a connecting rod rotatably penetrates into a hole on the curved top of the curved hole, and the end of the connecting rod is provided with a curved matchingportion for matching with the corresponding curved holes. The present invention also discloses a test method using the fixture for performing a tensile test. The curved matching portion cooperates with the curved hole to realize the function of partial spherical hinge, realizes the function of automatic centering, ensures axial stretching in a tensile process of a test piece, and avoids the problem of eccentricity.

Owner:ZHENGZHOU UNIV

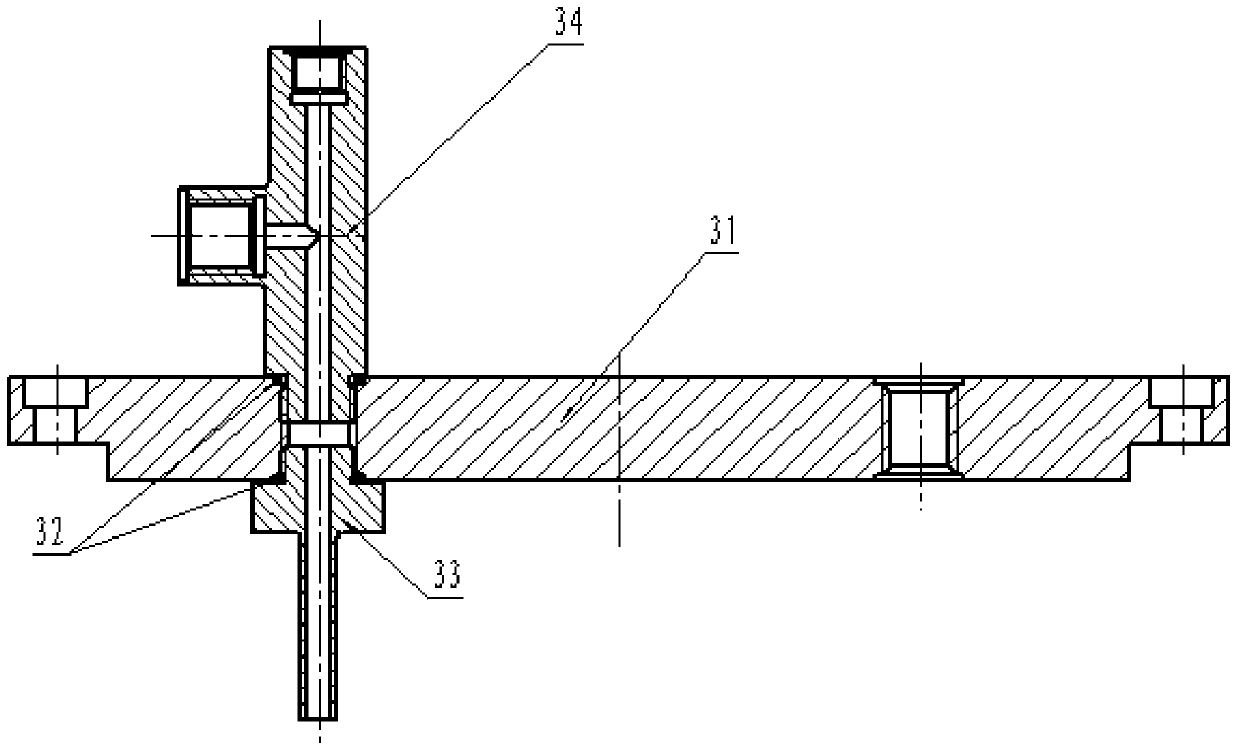

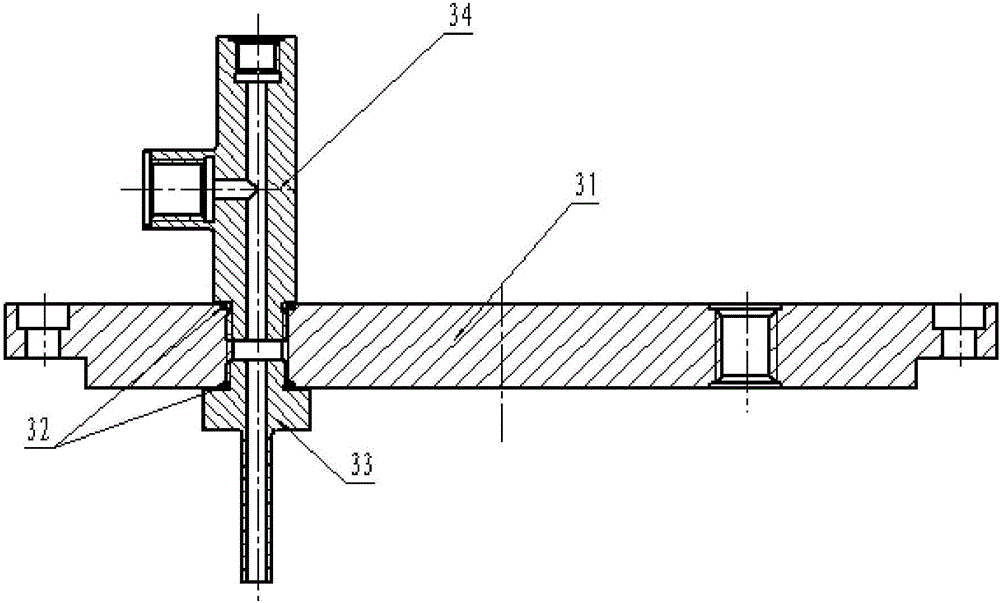

Metal hydrogen embrittlement sensitivity testing system

InactiveCN106872270ATo achieve the purpose of the testSolve the technical problems of long test periodWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesBody shapeElectrical control

The invention relates to a metal hydrogen embrittlement sensitivity testing system, comprising an independent loading unit, a stainless steel water tank arranged in the independent loading unit, a central heating fluid-flushing station arranged on the side face of the independent loading unit, an electrical control cabinet arranged on the side face of the central heating fluid-flushing station, and a centralized recycle bin arranged on the side face of the electrical control cabinet, wherein the stainless steel water tank is in a trough body shape; the stainless steel water tank is internally provided with a constant temperature environment box; the upper end of the constant temperature environment box is provided with a first temperature sensor; the constant temperature environment box is internally provided with a round bar sample in a penetrating way; a threaded compression sealing element used for sealing is arranged at the connecting part of the round bar sample and the side wall of the constant temperature environment box; another threaded compression sealing element used for sealing is arranged at the connecting part of the round bar sample and the side wall of the stainless steel water tank; anchorage device clamping pieces are also respectively arranged at the two ends of the round bar sample.

Owner:WATER CONSERVANCY & HYDROPOWER SCI RES INST OF LIAONING PROVINCE +1

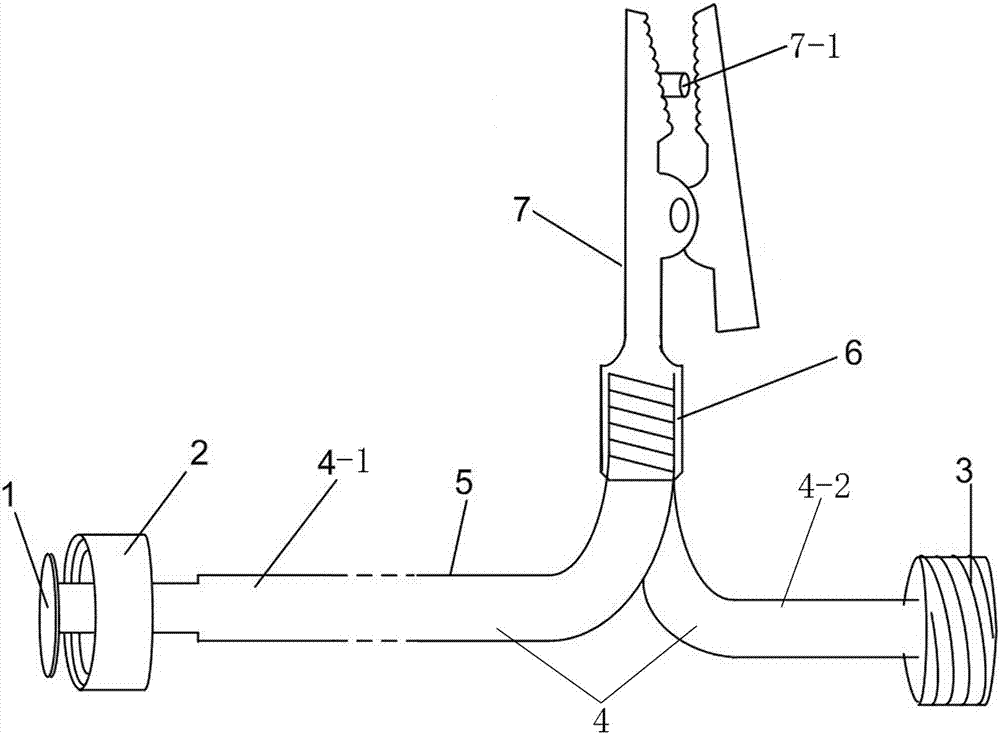

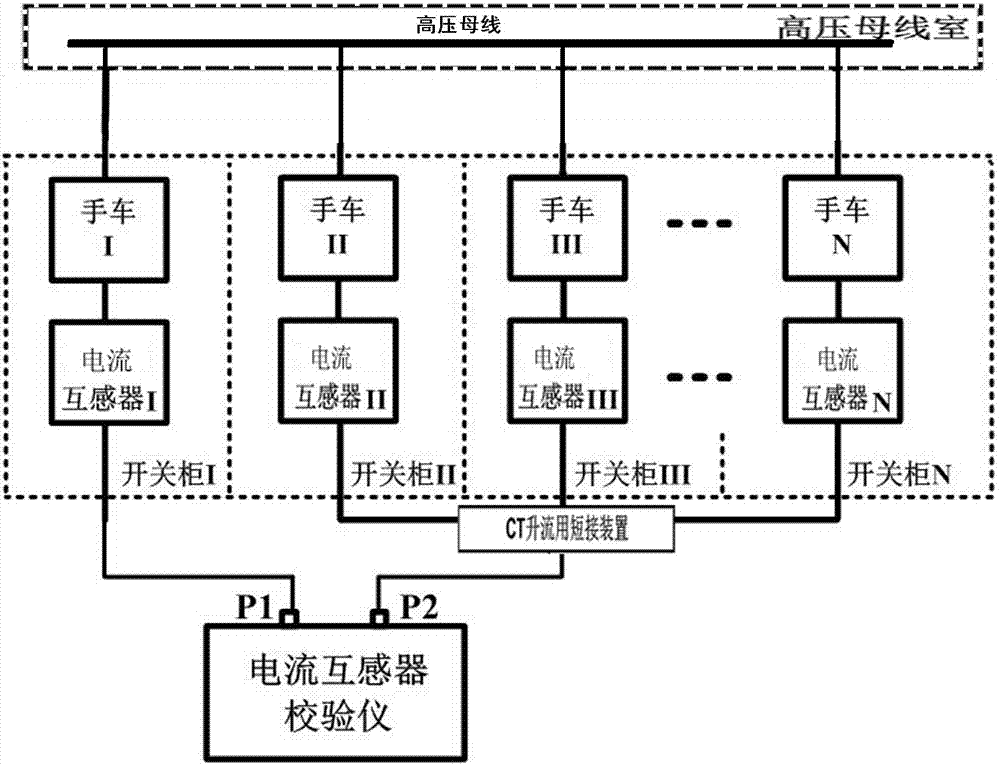

Short-circuit apparatus for handcart type switch cabinet CT current-rising test

InactiveCN107579471ATo achieve the purpose of the testReduce work intensitySwitchgearCopper wireEngineering

The invention discloses a short-circuit apparatus for a handcart type switch cabinet CT current-rising test. The short-circuit apparatus comprises a test clamp, a copper wire lug, two copper wires, acontact plate, a movable joint and a fixed joint; wherein one ends of the two copper wires are aligned and overlapped and fixedly connected with one clamp handle of the test clamp, the copper wire lugis used for tightly pressing the two copper wires, the other end of the first copper wire is connected with the contact plate, the movable joint is arranged on one side of the contact plate, the diameter of the contact plate is equal to the inner diameter of the movable joint, an inner thread is arranged on the inner wall of the movable joint, the other end of the second copper wire is connectedwith the fixed joint, an outer thread is arranged on the outer wall of the fixed joint, the movable joint and the fixed joint are matched and assembled to connect two short-circuit apparatuses. The apparatus is simple in structure, can replace manual wire clamping, and achieves safe, labor-saving and reliable operation. The acceptance, the calibration and the first-aid repair efficiency of the relay protection professional CT is improved. The working intensity and potential safety risk of workers are reduced.

Owner:广西电网有限责任公司桂林供电局

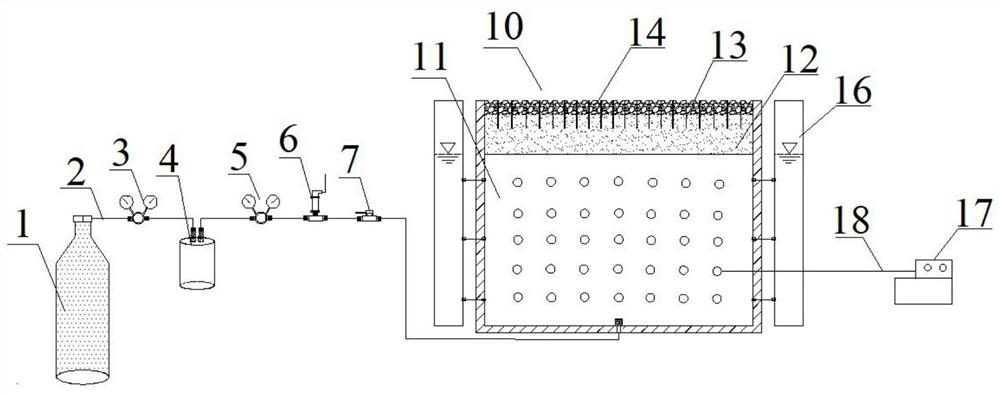

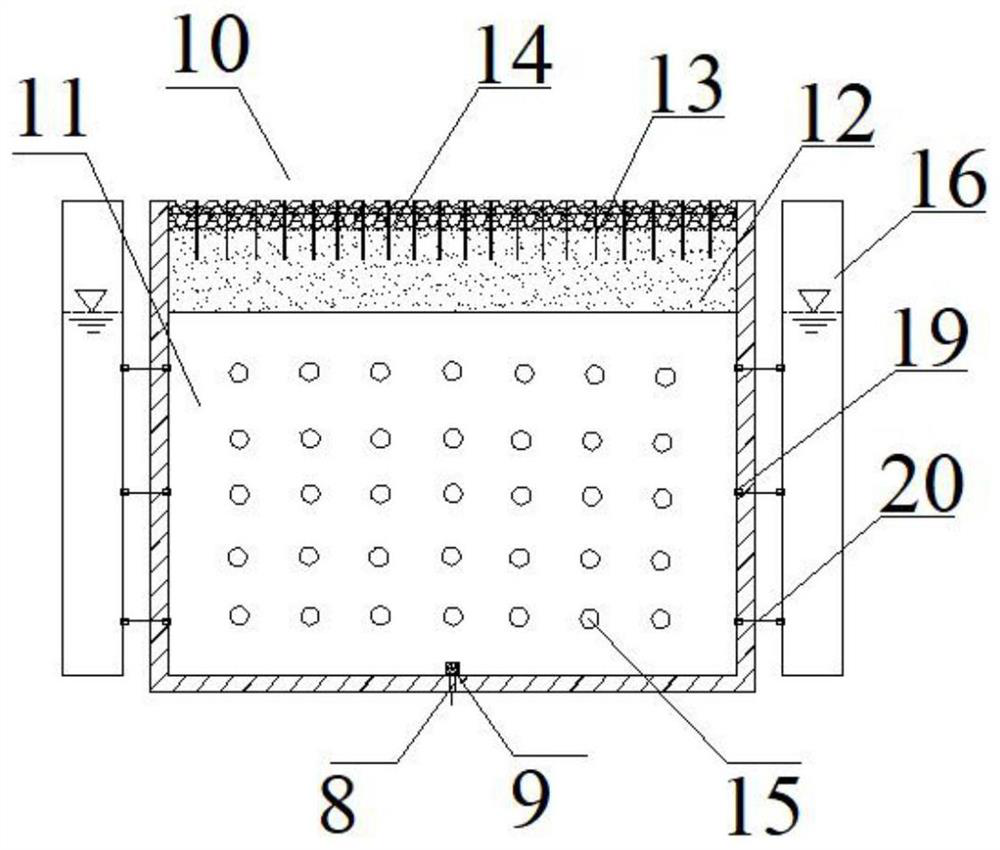

Polluted soil surfactant enhanced aeration test device and test method

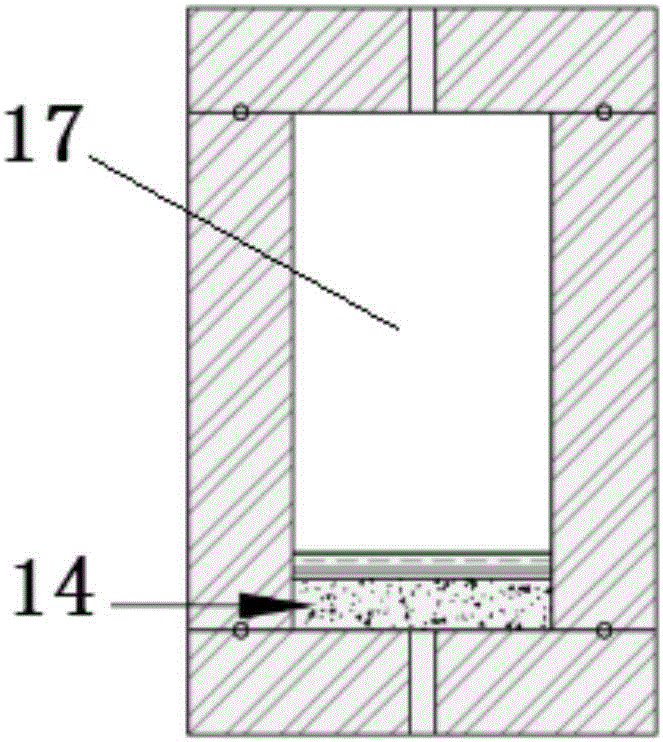

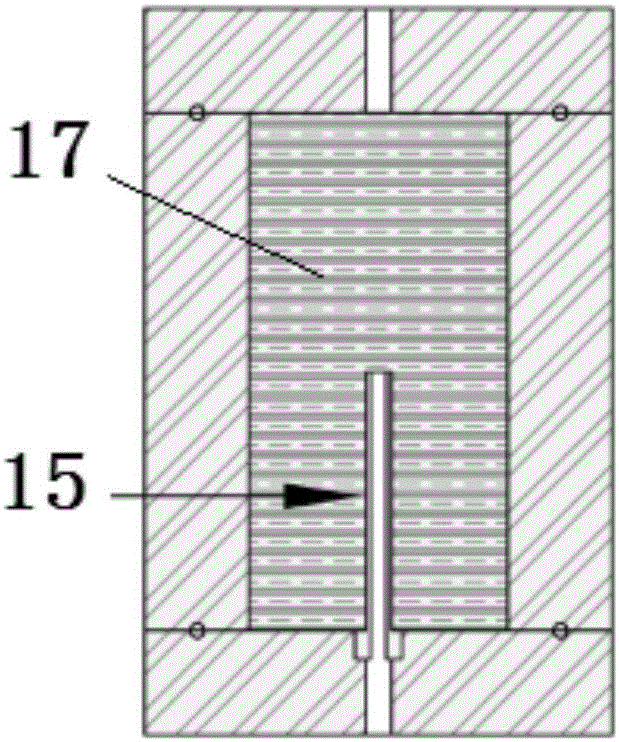

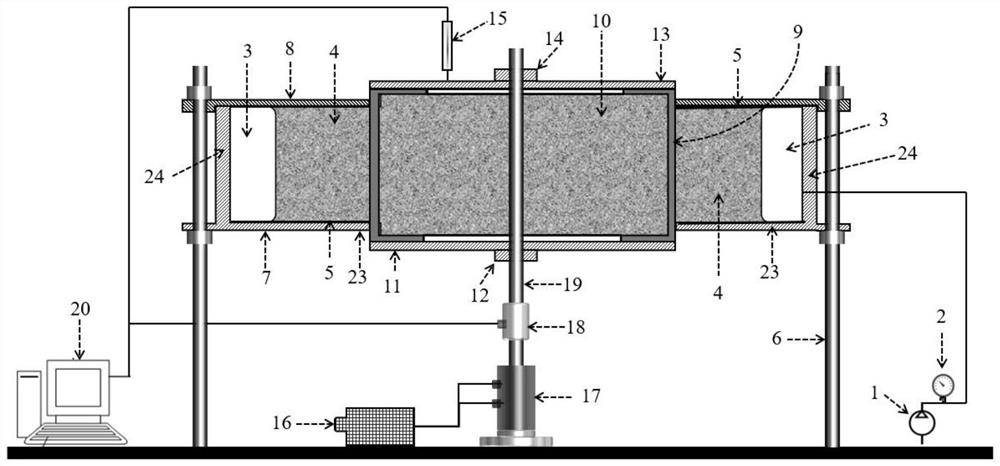

InactiveCN112684111AMonitor the removal effectEasy to control aeration test conditionsMaterial analysisPeristaltic pumpActive agent

The invention provides a surfactant enhanced aeration test device and a test method, which belong to the technical field of environmental geotechnical engineering. The method can be used for conventional aeration, enhanced aeration by integrally injecting the surfactant and enhanced aeration by locally injecting the surfactant. A main device comprises a test box, a sample layer, a coarse sand layer, an adsorption layer, a partition plate, a peristaltic pump, a water tank and the like. In the test process, VOCs can be adsorbed by controlling the injection positions of different surfactants and activated carbon in the adsorption layer in the test box, and the repair efficiency of conventional aeration, overall surfactant injection enhanced aeration and local surfactant injection enhanced aeration is quantitatively evaluated. And the influence of the surfactant injection position on the airflow mode, the pollutant removal efficiency and the airflow path control is further studied. The test device and the test method have important engineering practical significance and theoretical research value for expansion and application of the technical range of the aeration method.

Owner:HEFEI UNIV OF TECH +1

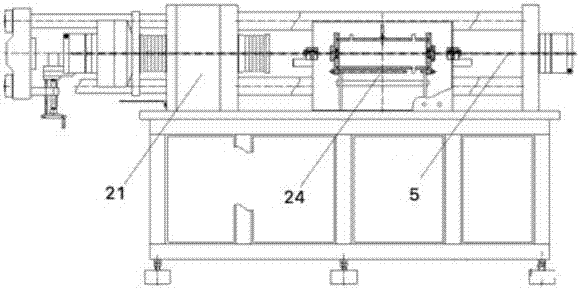

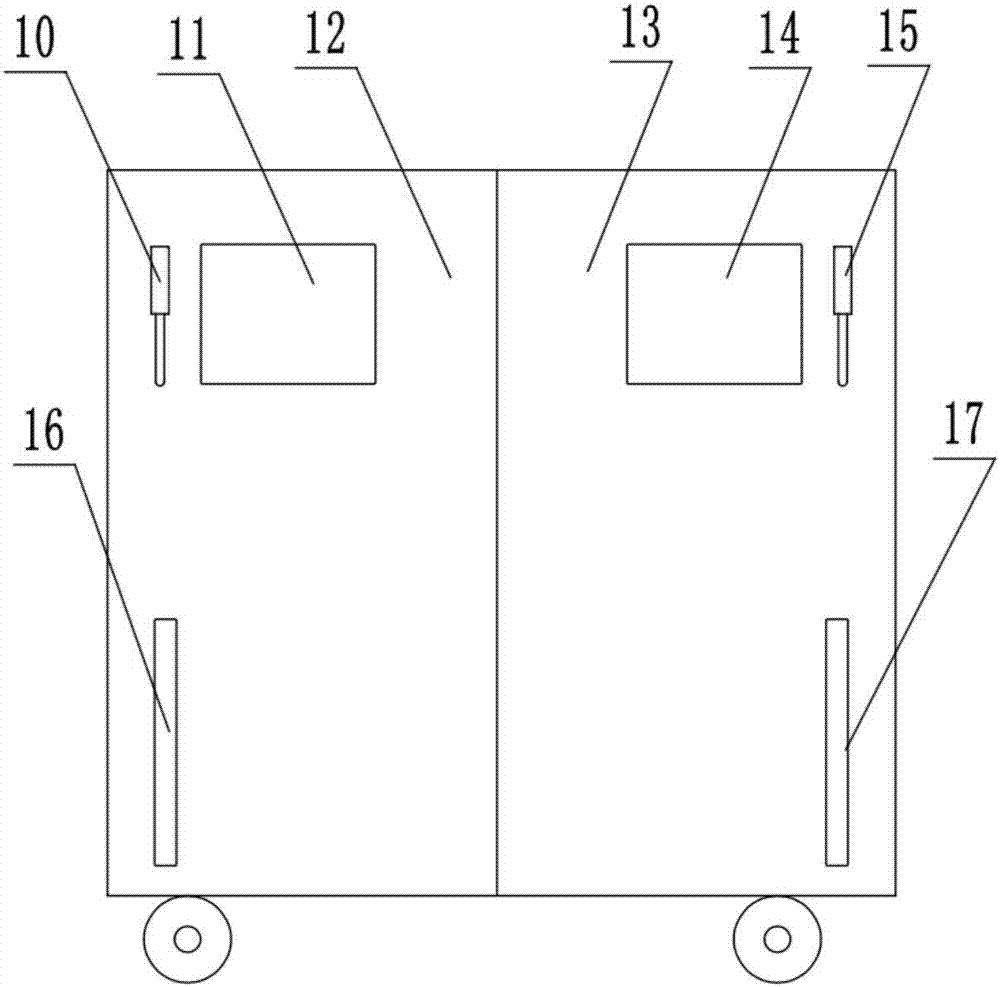

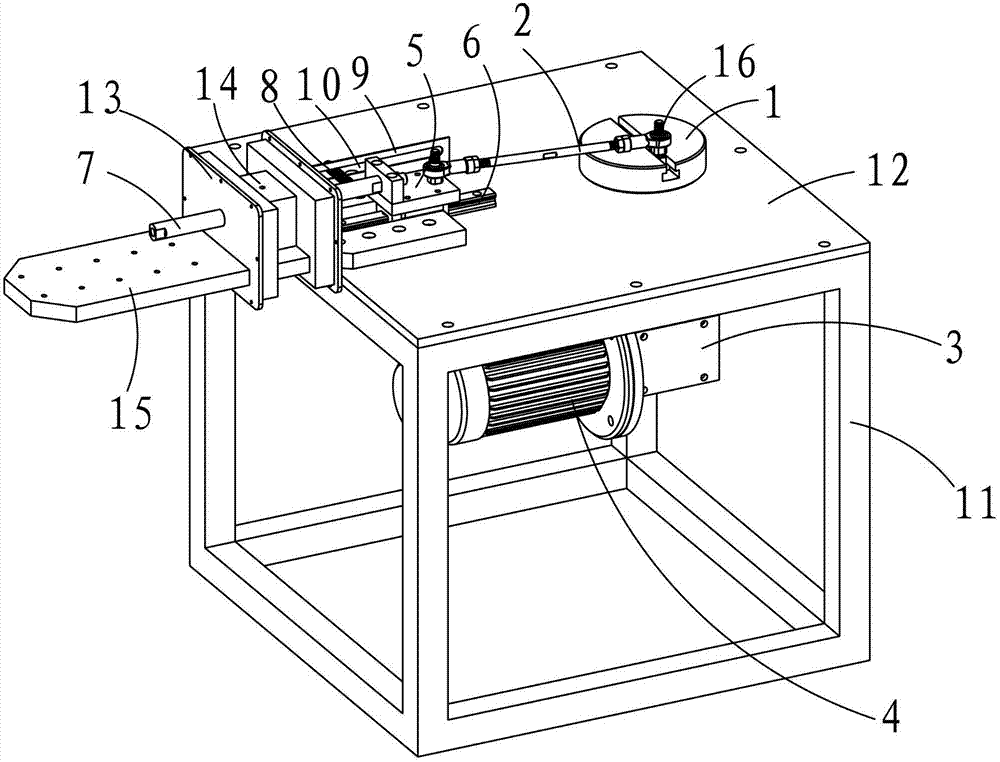

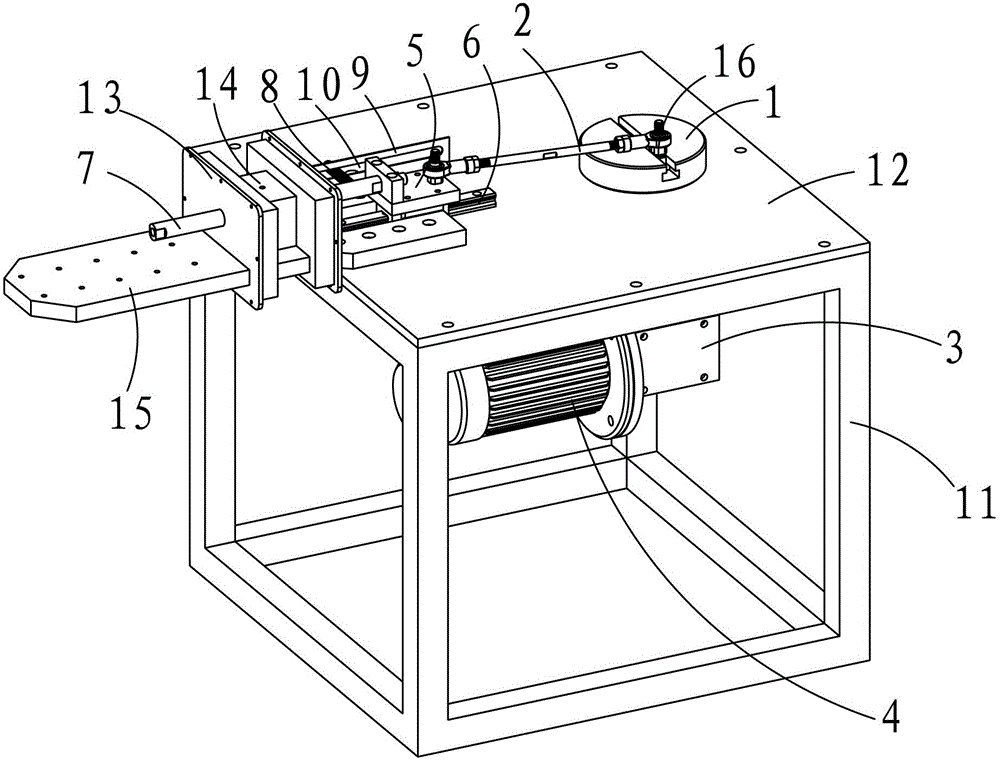

Driving mechanism used on dragline endurance test platform

The invention discloses a driving mechanism used on a dragline endurance test platform. The driving mechanism comprises a supporting frame, a turnplate which is connected with the supporting frame in a rotation manner through a first rotor shaft, a mounting hole which is formed in the turnplate and is used for connecting one end part of a drive rod, a motor and a speed reducer for driving the first rotor shaft to rotate, a sliding block fixedly connected with the other end part of the drive rod, a guide rail arranged on the supporting frame, a dragline mounting rack fixedly connected with the sliding block as well as a driving optical shaft arranged on the dragline mounting rack, wherein the mounting hole is deviated from the first rotor shaft, and the sliding block is arranged on the slide guide in a sliding manner; the sliding direction of the sliding block is perpendicular to an axial line direction of the first rotor shaft, the motor drives the turnplate to rotate, and then the drive rod is arranged in the mounting hole of the deviation rotating center; the drive rod can do reciprocating linear motion, and the drive rod drives the sliding block do reciprocating linear motion and further drives the dragline mounting rack to do reciprocating linear motion; therefore, the purpose of a test is achieved, the structure is simple, the use is safe, and a test effect is better.

Owner:金新民

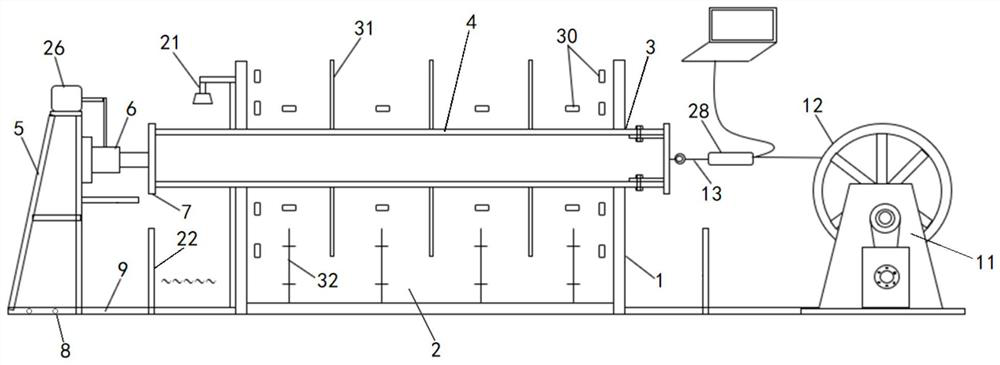

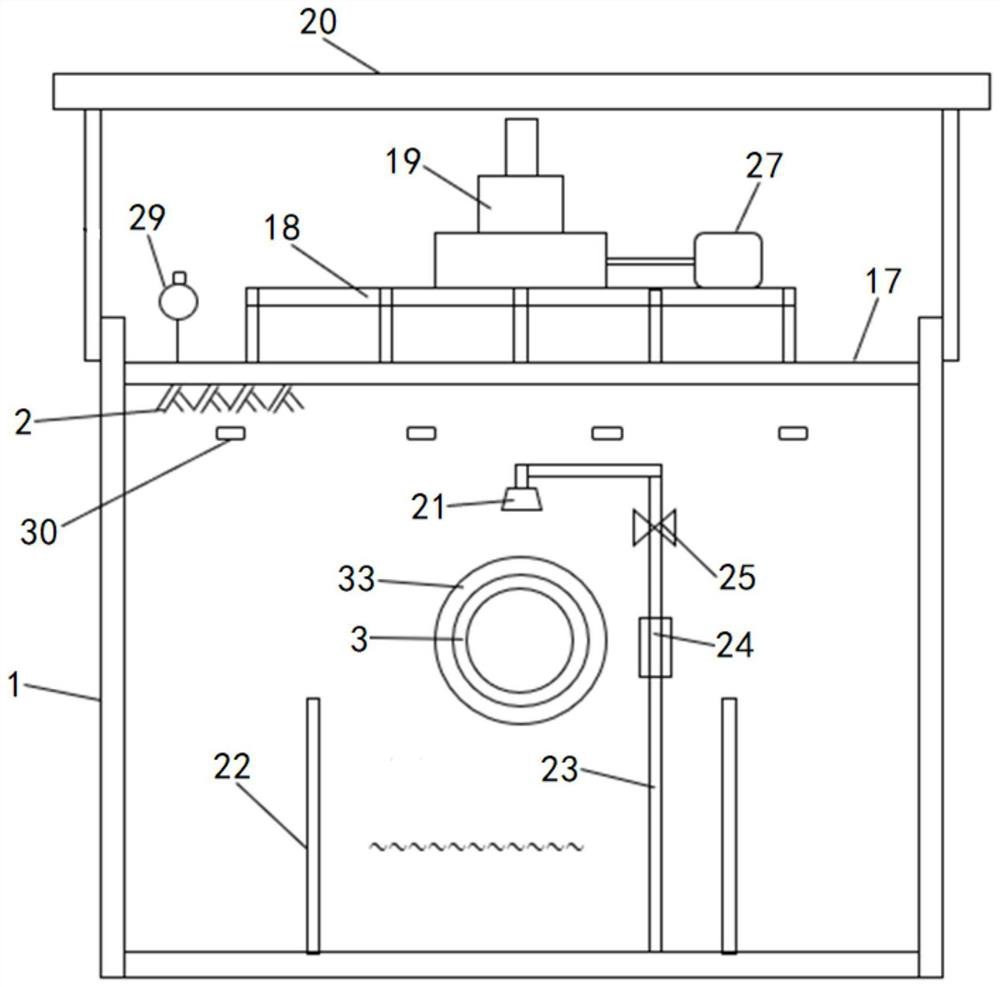

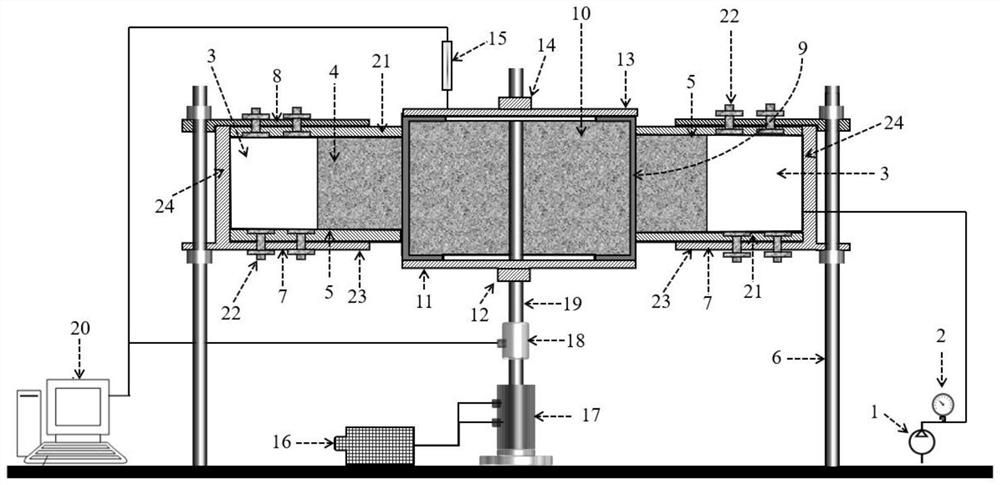

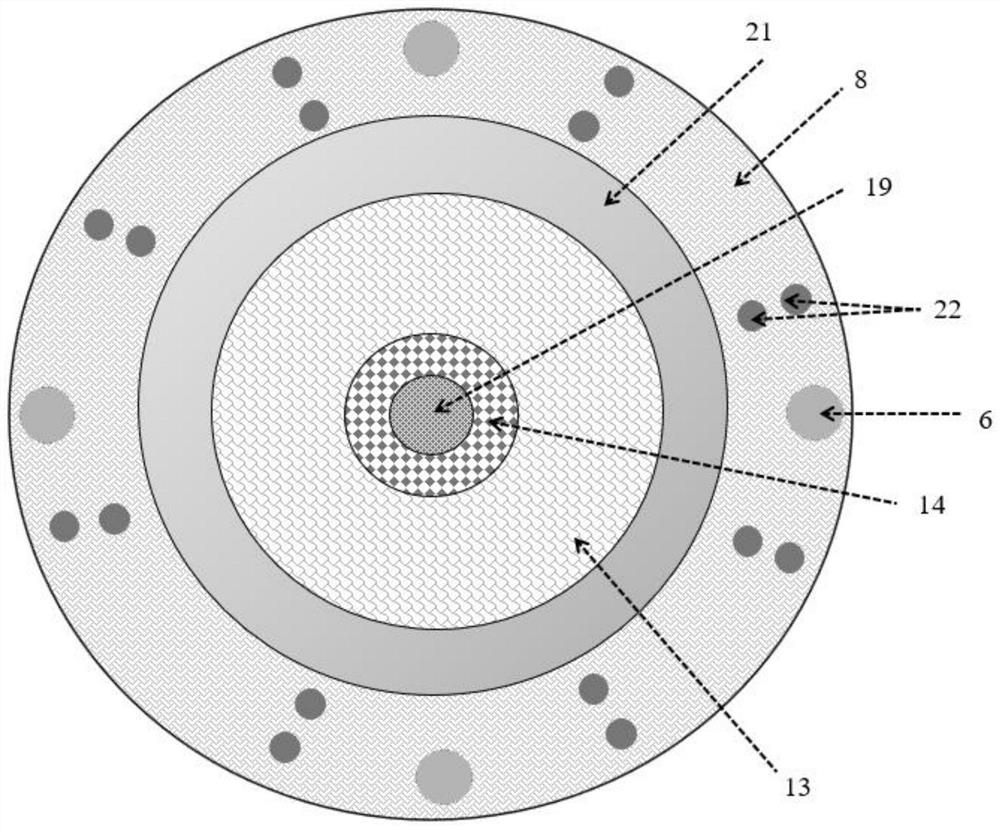

Indoor test simulation device and method for pipe pulling and jacking construction

PendingCN114002076ATo achieve the purpose of the testReasonable structureMaterial strength using tensile/compressive forcesStructural engineeringPipe

The invention provides an indoor test simulation device for pipe pulling and jacking construction. The device comprises a transparent box body, the top surface of the box body is open, a vertical loading mechanism is arranged above the box body, a test soil body is arranged in the box body, two opposite side surfaces of the box body are both provided with circular top holes, and simulation pipelines are inserted into the circular top holes; and the two ends of the simulation pipeline can penetrate out of the circular top holes in the two sides, a guniting assembly is arranged at one circular top hole, and a first horizontal loading mechanism and a second horizontal loading mechanism are arranged on the outer side of the circular top hole, located on the two sides of the box body correspondingly and used for loading the two ends of the simulation pipeline. In the test soil body, the vertical loading mechanism and the horizontal loading mechanisms are all provided with measuring devices, relevant parameters needed by the test are comprehensively and accurately measured by means of the measuring devices, the test purpose is well achieved, and a model experiment for simulating stratum deformation caused by pipe pulling and jacking construction under multiple on-site conditions and determining the optimal proportion of lubricating mud can be carried out.

Owner:中交四航局第七工程有限公司 +3

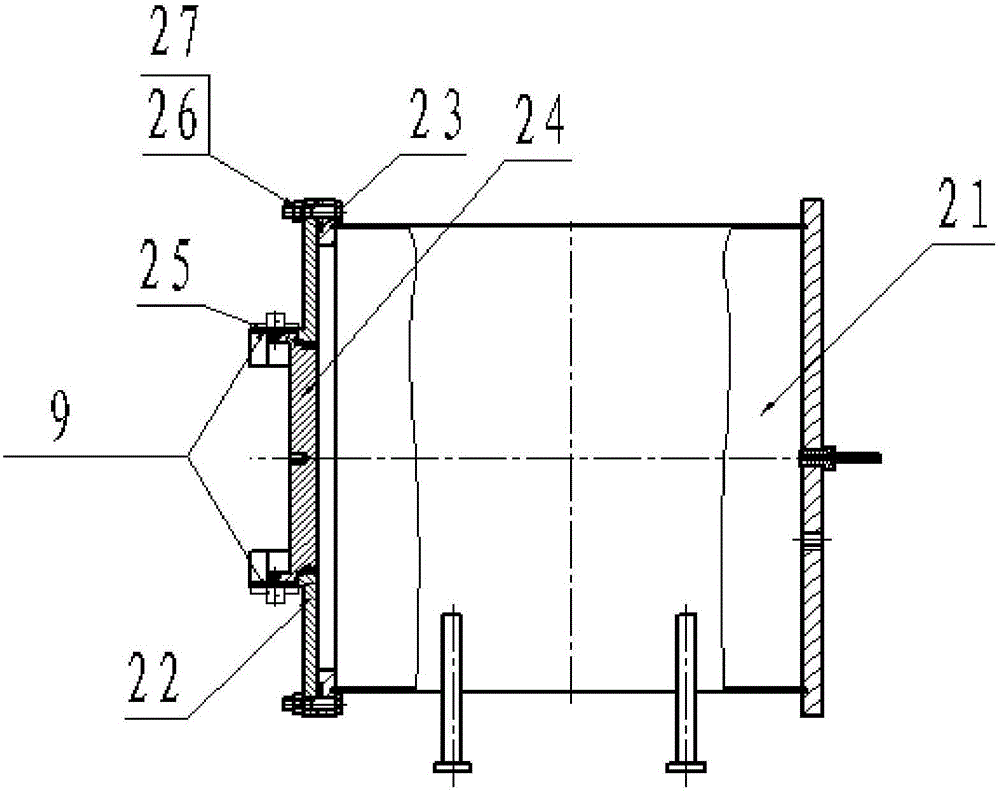

Multifunctional visual research device for bentonite hydraulic power and air pressure splitting features

InactiveCN106370525ARealize visualizationRealize the disassembly combinationMaterial strength using tensile/compressive forcesSodium BentoniteEngineering

The invention relates to a multifunctional visual research device for bentonite hydraulic power and air pressure splitting features. The research device comprises a pressurizing space, a data collecting unit and a pressure control unit, wherein the data collecting unit is arranged above the pressurizing space, and the pressure control unit is connected with the pressurizing space. The pressurizing space is defined by a transparent top cover, a sleeve and a transparent base, the transparent top cover and the transparent base are arranged at the two ends of the sleeve in a sleeved mode respectively, the transparent top cover is fixedly connected with the transparent base through a bolt, the data collecting unit is arranged above the transparent top cover, and a connector is arranged on the transparent base and connected with the pressure control unit. Compared with the prior art, the multifunctional visual research device has the advantages of having selectable functions, being high in reliability, visual, low in cost, easy to operate and the like.

Owner:TONGJI UNIV

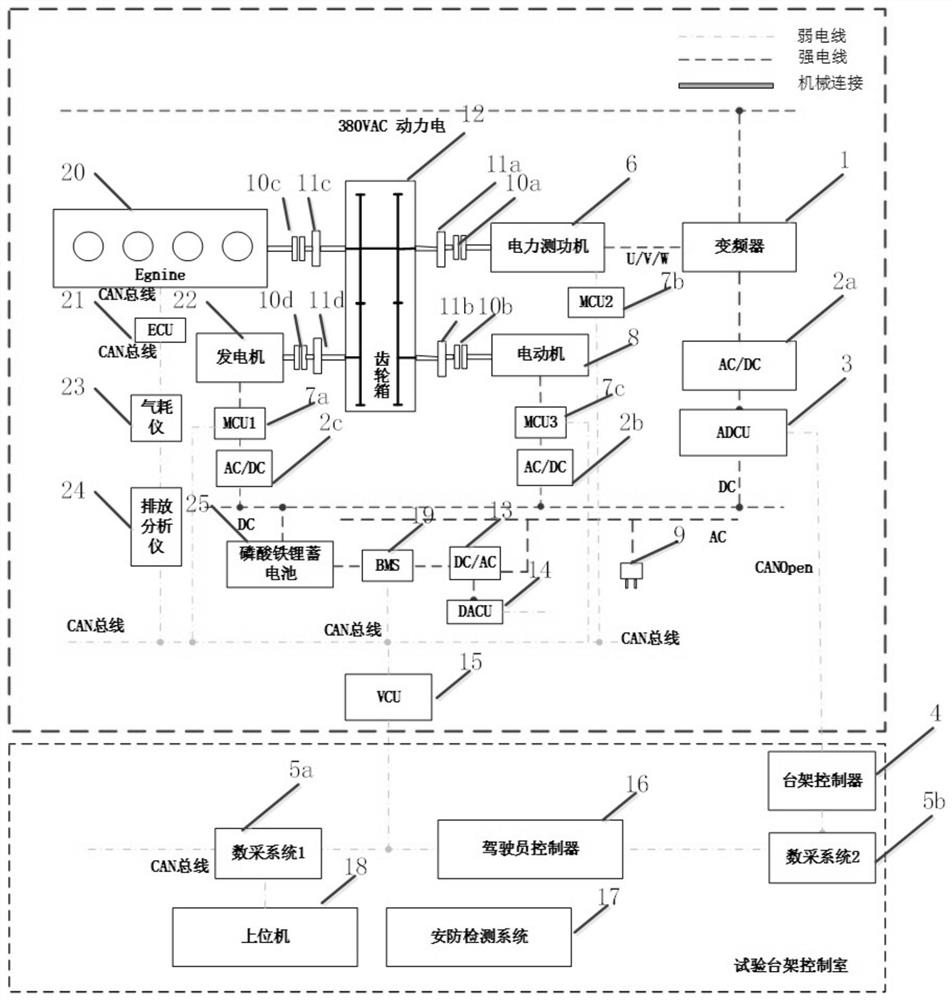

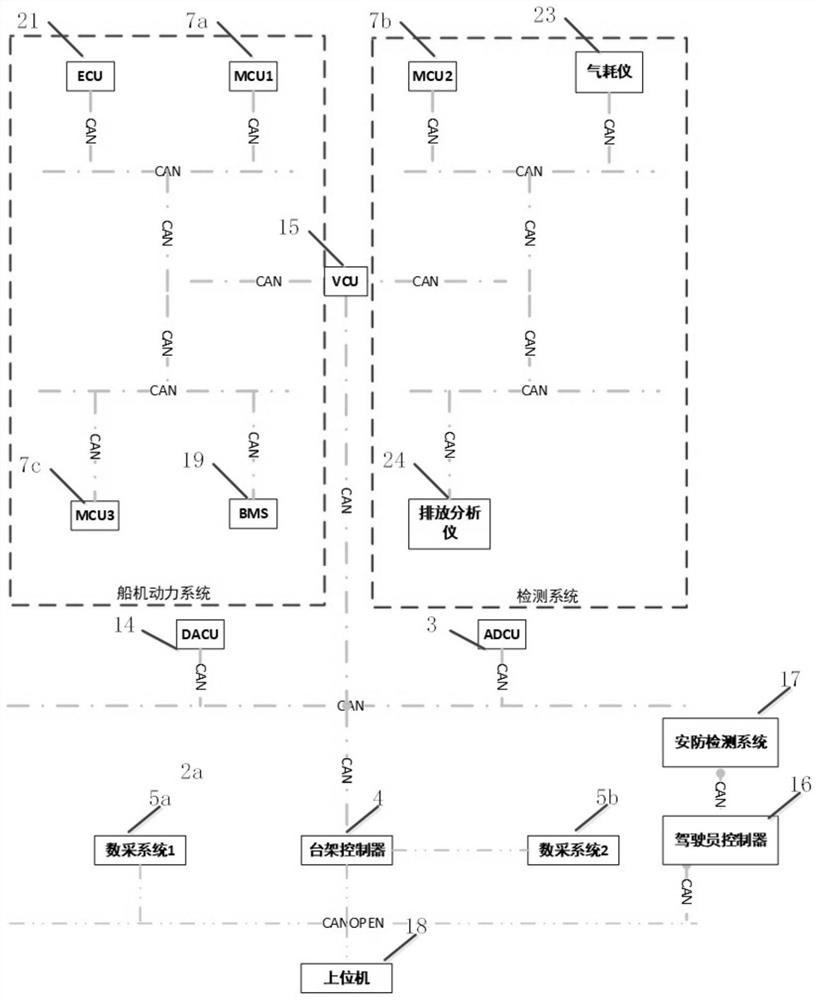

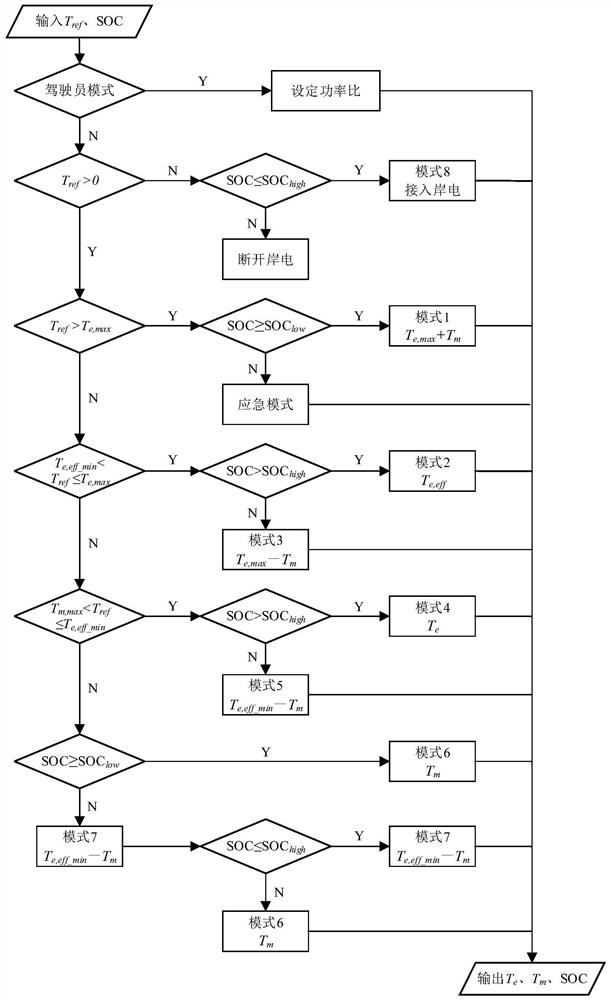

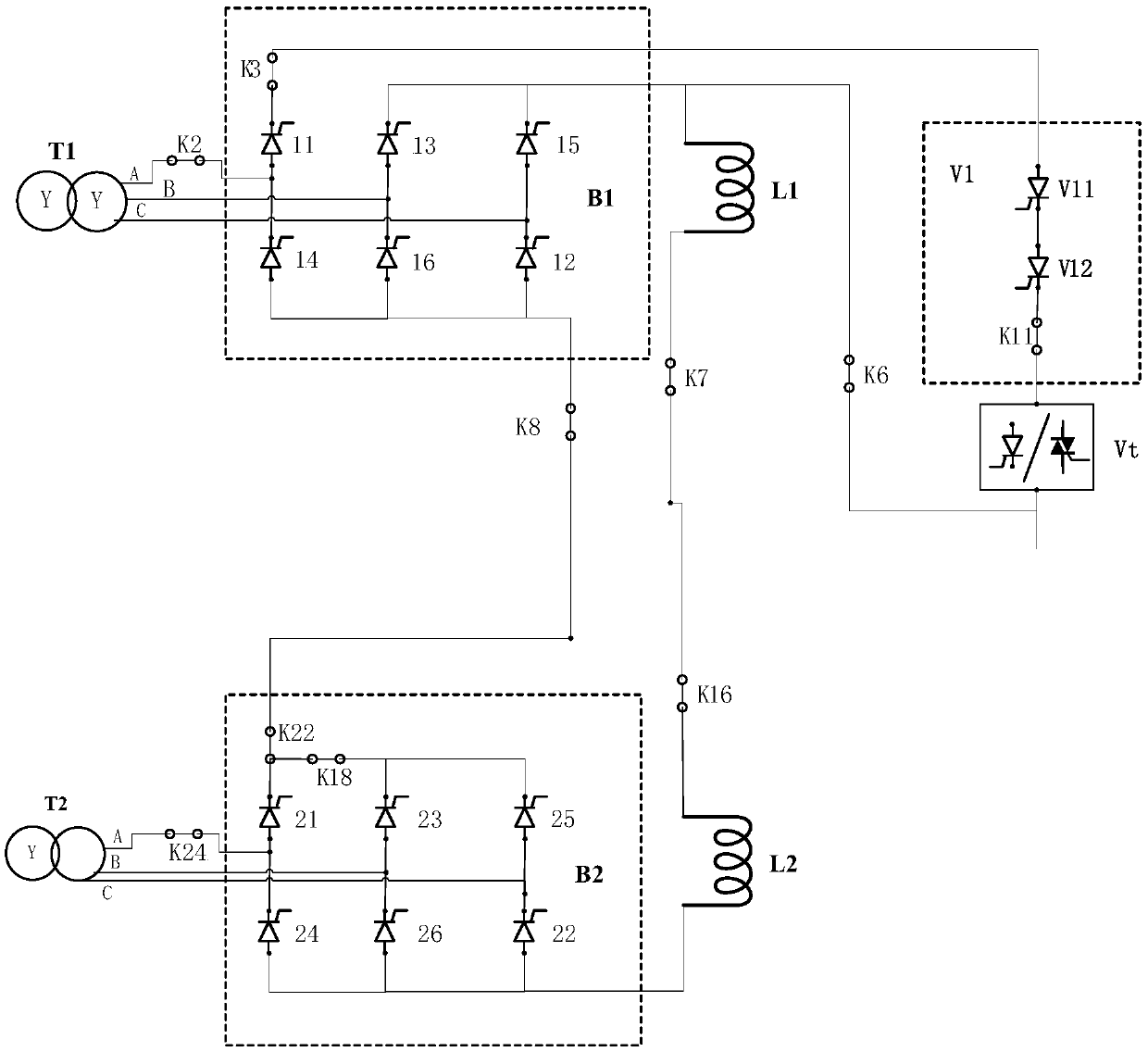

Gas-electric series-parallel ship hybrid power test bed with energy management system and control method of gas-electric series-parallel ship hybrid power test bed

InactiveCN112711248AWide power coverageMeet power needsElectric testing/monitoringVessel designingFrequency changerGear wheel

According to the pneumoelectric series-parallel ship hybrid power test bed with the energy management system and the control method thereof, an electric dynamometer is connected with a first gear through a first clutch and a first torque flange, and a motor is connected with a second gear through a second clutch and a second torque flange; the gas engine is connected with a third gear through a third clutch and a third torque flange, the generator is connected with a fourth gear through a fourth clutch and a fourth torque flange, the storage battery is connected with the test bed direct-current main network, and the external power source is connected with the test bed alternating-current auxiliary network and connected with the storage battery through a power transformation device. The generator and the motor are respectively connected with the test bench DC main network, and the electric dynamometer is connected with the test bench DC main network through the frequency converter. According to the invention, the gas machine and the motor can independently or cooperatively drive the electric dynamometer, so that the emission of pollution gas is greatly reduced. Meanwhile, monitoring control of each device of the test bed is realized, the controllability of the test bed is improved, and the investment cost is reduced.

Owner:HARBIN ENG UNIV

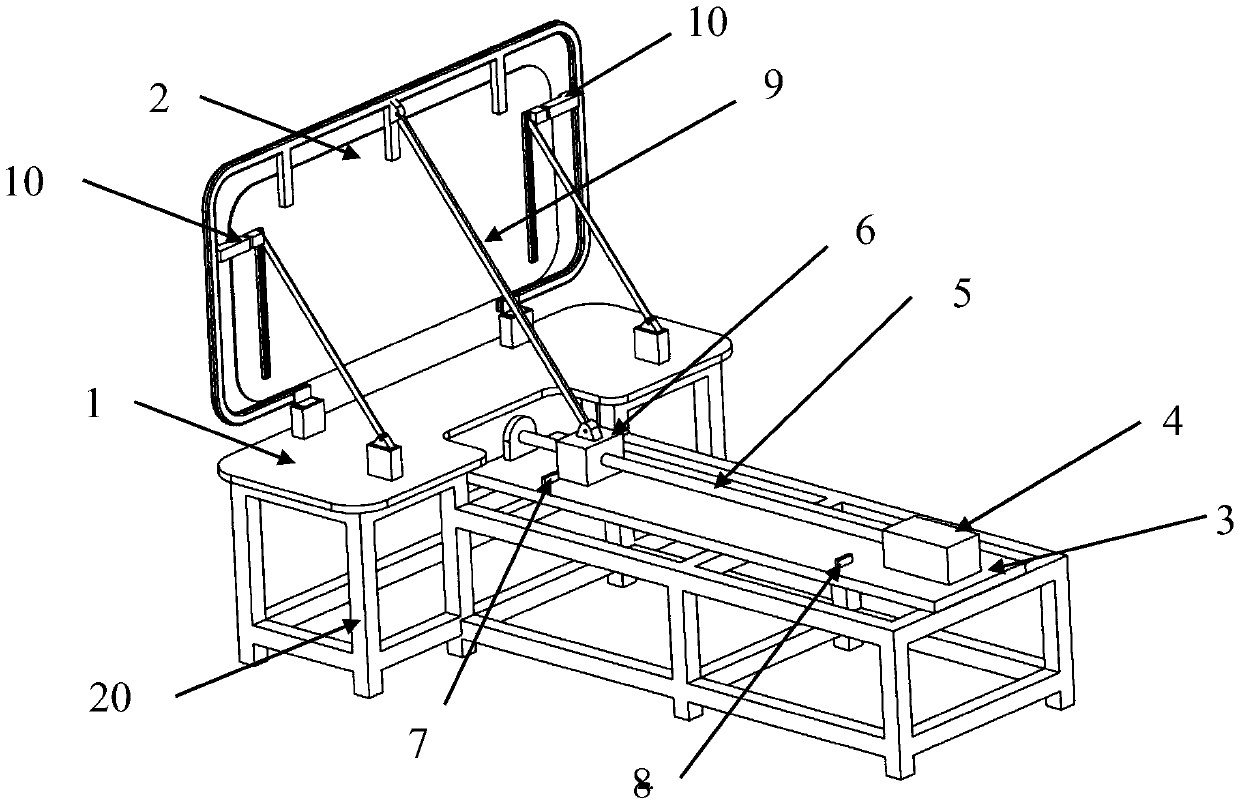

Fatigue testing device for astronautical folding dining table switching time

PendingCN109682623AReduce labor costsReduce trial riskStructural/machines measurementFatigue testingHuman power

The invention relates to a fatigue testing device for an astronautical folding dining table switching time. The device is characterized by comprising an experimental framework which is used for simulating a capsule wall, a rack, a switching mechanism and a PLC control module, a folding dining table is installed on the experimental framework through a hinge, the rack is fixedly connected with the switching mechanism, the switching mechanism comprises a servo motor, a lead screw, a sliding block and a connecting rod, the servo motor is connected with the lead screw, the lead screw is slidably connected with a sliding block, a linear guiding mechanism is formed by the lead screw and the sliding block, the sliding block is hinged to one end of the connecting rod, the other end of the connecting rod is hinged to a testing member, and the servo motor is connected with the PLC control module. The fatigue testing device has the advantages that a mechanical mechanism is combined with PLC control, the switching on and off of the folding dining table by a worker can be simulated, automatic testing is achieved, manual operation performed by the worker is replaced, labor cost is reduced, testing risks are reduced, testing purposes are achieved to help extensive production application, and the fatigue testing device has significant production practical meanings.

Owner:TIANJIN AEROSPACE RELIA TECH +1

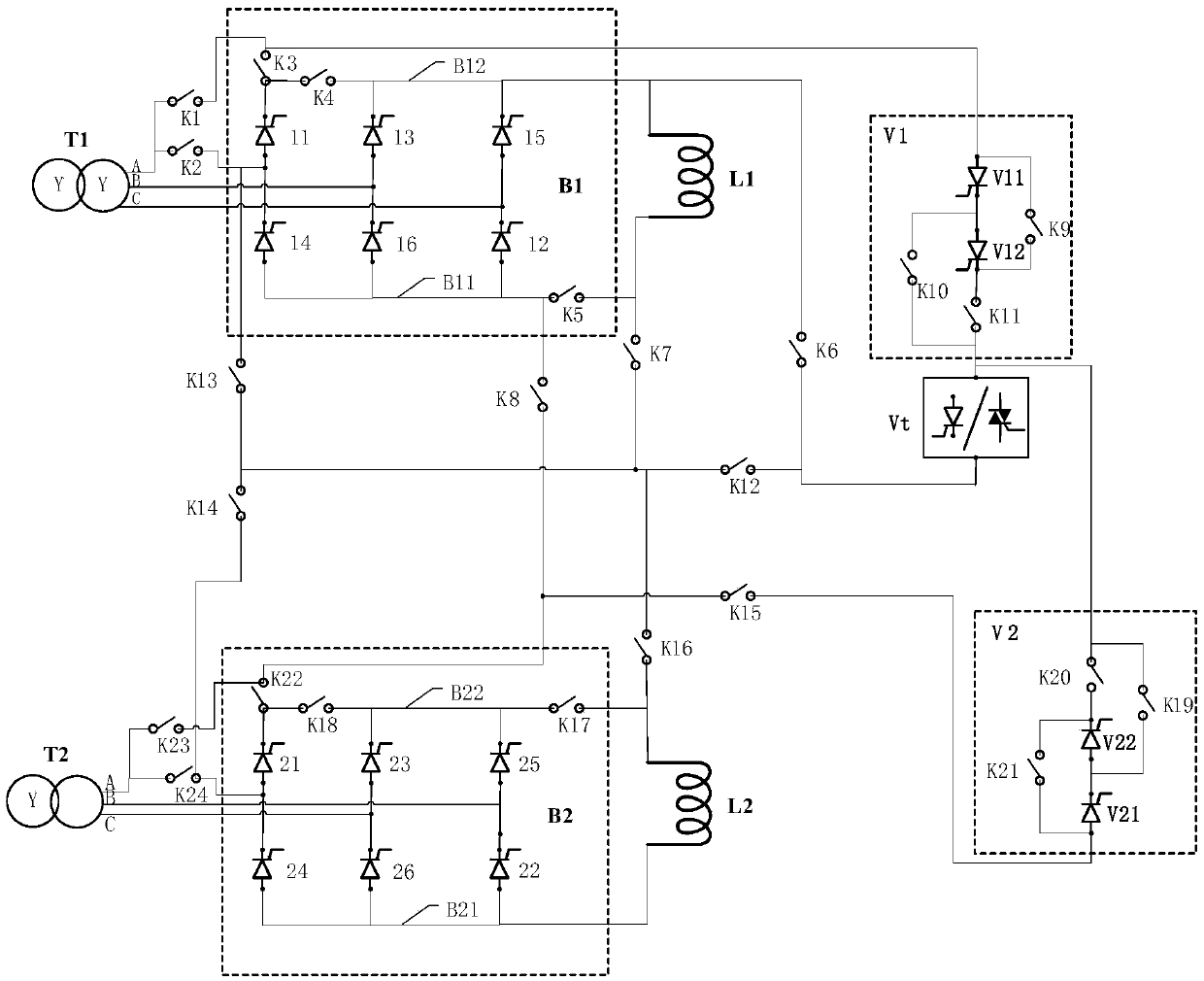

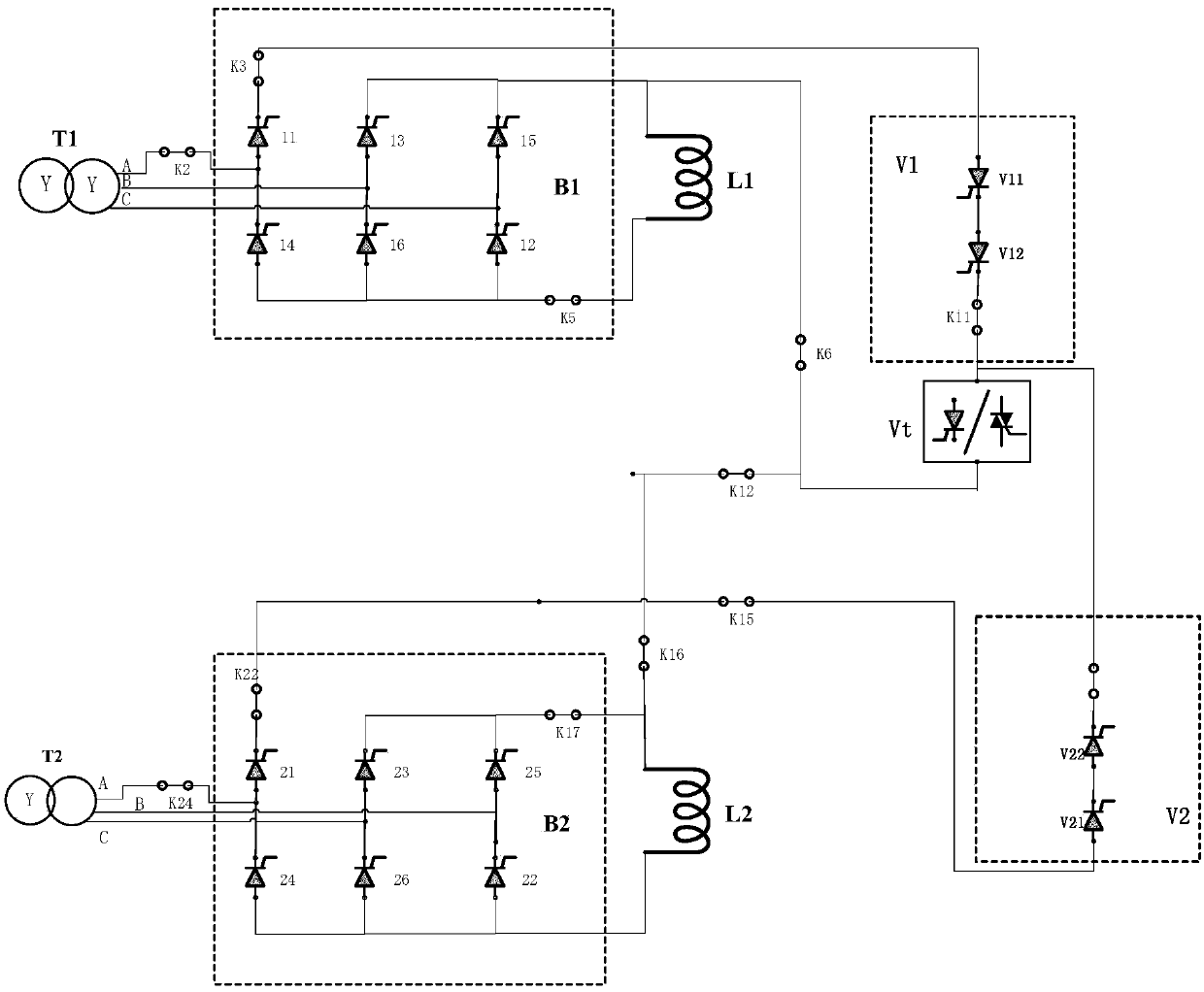

Electrical test device of thyristor valve and power supply device of electrical test device

ActiveCN111273096ATo achieve the purpose of the testEnvironmental/reliability testsIsolation valveTransformer

The invention discloses an electrical test device of a thyristor valve and a power supply device of the electrical test device. The power supply device specifically comprises a first converter transformer, a second converter transformer, a first smoothing reactor, a second smoothing reactor, a first 6-pulse rectifier bridge, a second 6-pulse rectifier bridge, a first isolating valve, a second isolating valve, a first switch, a second switch, a third switch, a fourth switch, a fifth switch, a sixth switch, a seventh switch, an eighth switch, a twelfth switch, a thirteenth switch, a fourteenth switch, a fifteenth switch, a sixteenth switch, a seventeenth switch, an eighteenth switch, a twenty-second switch, a twenty-third switch and a twenty-fourth switch. When a 6-pulse output request or a12-pulse output request is received, the corresponding switch is controlled to be closed, and the connection mode of the secondary coil of the second converter transformer is controlled, so that the purpose of testing the thyristor valve to be detected in a 6-pulse rectification mode or a 12-pulse rectification mode can be achieved.

Owner:XIAN HIGH VOLTAGE APP RES INST CO LTD

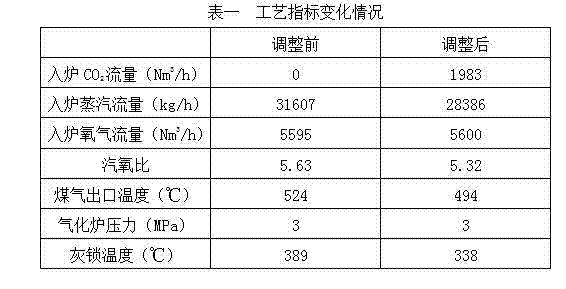

Method for gasification and compression of crushed coal

InactiveCN102643672AEmission reductionReduce consumptionCombustible gas productionHydrogenWater vapor

The invention relates to a method for gasification and compression of crushed coal, which belongs to the technical field of continuous gasification by compression; the invention aims to provide a method for gasification and compression of crushed coal for changing components of gasification agent, reducing consumption of water vapor, and lowering exhaust of carbon dioxide; according to the technical scheme, gasification agent consists of carbon dioxide, water vapor and pure oxygen, the ratio of weight portions of carbon dioxide to water vapor to pure oxygen is (0.4-0.52):(3.2-3.6):1; according to the method, CO2 is used for replacing part of water vapor in gasification agent to react with a raw material coal, the consumption of water vapor is reduced, the output of coal gas waste water is reduced, the temperature of coal gas of gasifier products and the ratio of hydrogen to carbon are lowered, so that the energy consumption of a system is effectively reduced, and the exhaust of CO2 is lowered at the same time.

Owner:SHANXI LUAN MINING GRP

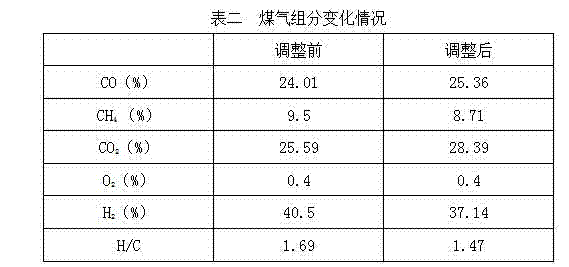

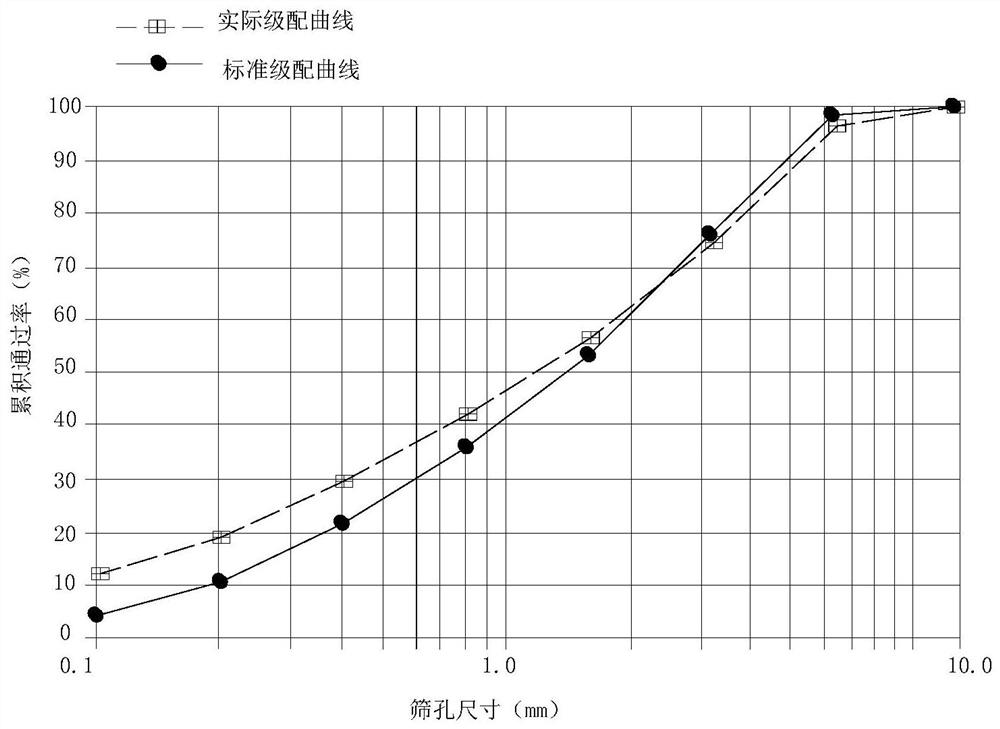

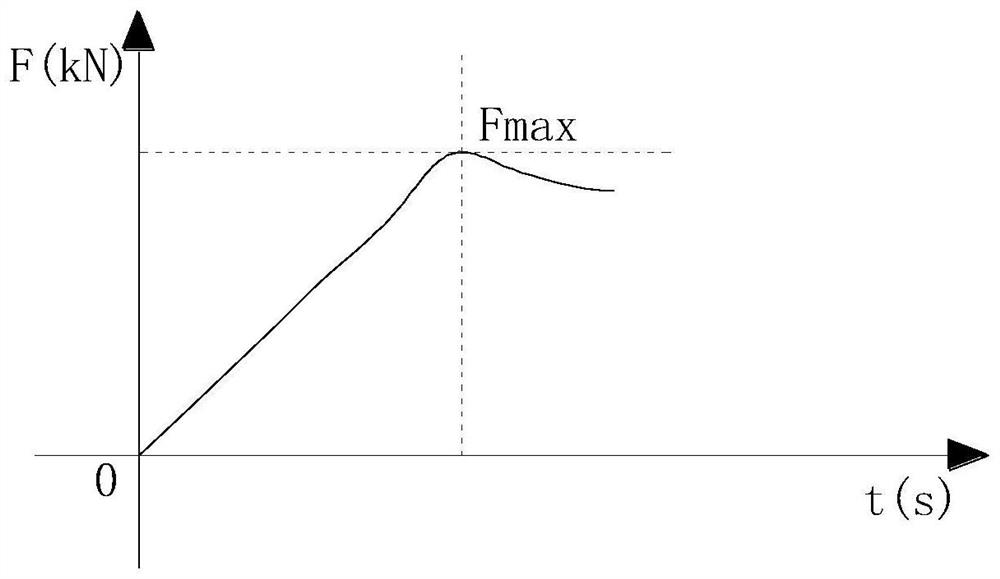

Bottom friction coefficient calibration system for gravity type structure stability test

ActiveCN111610144AIngenious ideaEasy to operateClimate change adaptationUsing mechanical meansPull forceFrictional coefficient

The invention provides a bottom friction coefficient calibration system for a gravity type structure stability test, and belongs to the field of friction coefficient tests. The system is implemented as follows: (1), carrying out pre-measurement preparation; (2), manufacturing a test gravity type structure; (3), grading and sorting rock blocks of a structural foundation cushion layer; (4), throwingand filling rock blocks in a foundation trench and carrying out leveling; (5), erecting and fixing a force measuring assembly; (6), calibrating and debugging a force measuring system; (7), arrangingthe structure on a rock block foundation; (8), connecting the structure and a force measuring system traction rope; (9), measuring tension and calculating a friction coefficient; and (10), comparing the friction coefficient with a standard value, and judging whether the product is qualified; if not, carrying out roughening measure treatment compensation on the bottom of the gravity type structure,repeating work from steps (8) to (10), ending the measuring under the condition of qualification and carrying out a stability test. The system is ingenious in conception and easy to operate, and makes up the influence of different model materials and prototypes caused by reduction of the test scale, so that the test precision is ensured and the working efficiency is greatly improved.

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T

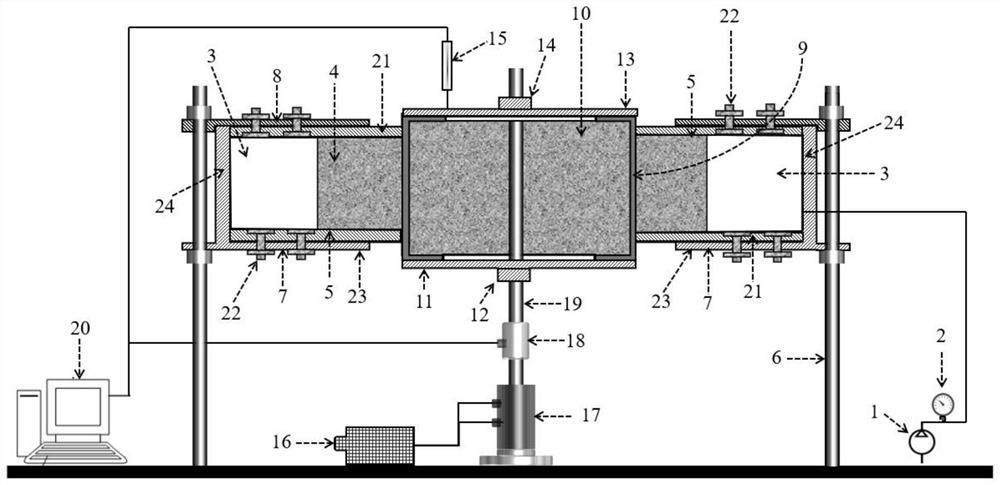

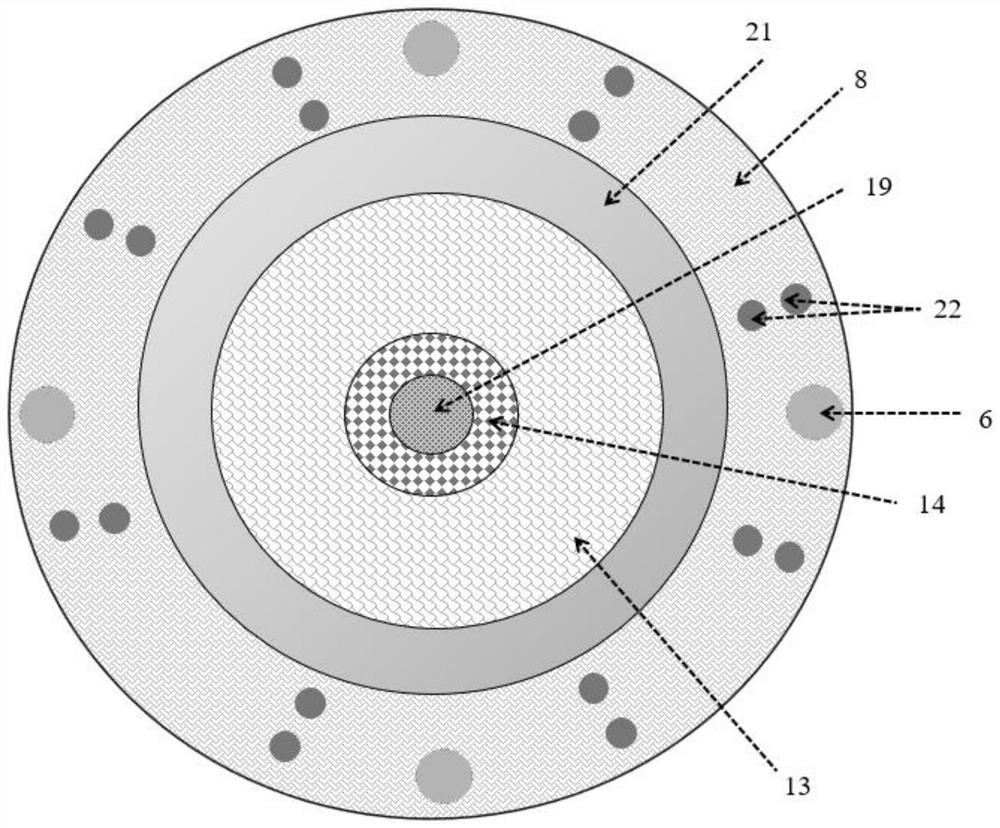

Waste tire-soil vertical interface shear characteristic testing device

PendingCN114166659AOvercoming the defects of shear mechanical propertiesRealize determinationMaterial strength using steady shearing forcesControl systemStructural engineering

The invention discloses a waste tire-soil vertical interface shear characteristic testing device which comprises a sample system, a confining pressure loading system and a servo control system, the sample system comprises an actuating table top cover, an actuating table base and a waste tire horizontally arranged between the actuating table top cover and the actuating table base, the actuating table top cover and the actuating table base are oppositely arranged up and down, and the waste tire is uniformly filled with a soil sample II; the confining pressure loading system comprises an annular shearing box arranged on the radial outer side of the sample system as well as a confining pressure air bag and a soil sample I which are sequentially filled in the annular shearing box from outside to inside in the radial direction, the soil sample I is in contact with the cylindrical side surface of the waste tire, and a horizontal load is provided through the confining pressure air bag; the servo control system is used for adjusting the height position of the sample system and providing a load in the vertical direction, a detachable base plate is arranged in the annular shear box, the sample system is connected with the displacement meter, and the servo control system is connected with the stress sensor. The device is suitable for carrying out shear test on the waste tire-soil vertical interface under the conditions of different burial depths and sizes.

Owner:CHANGSHA UNIVERSITY

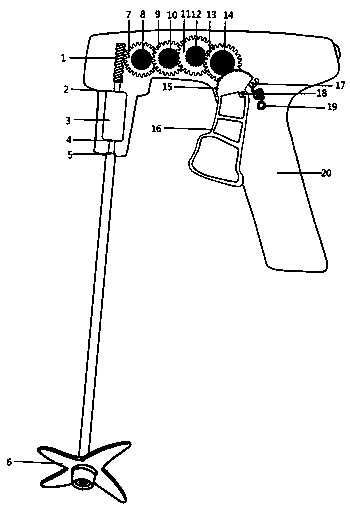

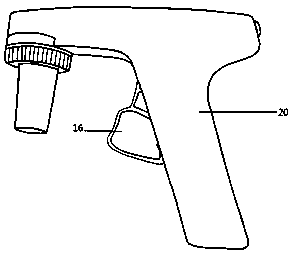

Detachable handheld crusher

InactiveCN111570036ANo strangenessNo cross contaminationGrain treatmentsGear wheelMaterial consumption

The invention discloses a detachable handheld crusher. The detachable handheld crusher comprises a crusher body. The crusher body comprises a handheld device, a start device, a rotating device, a gearset and a turbine device. The handheld device comprises a handle and a base. The start device is arranged at the position of the handle. The start device comprises a start gear, an extension hook, anut and an extension spring. The start gear is connected with the drive gear set, the other end of the gear set is connected with the turbine device, and the turbine device comprises bearings, a turbine fixing device and a clamping groove device. Manpower consumption caused by manual cutting-up and the purchase cost of a pulp refiner are reduced, the crushing rate is stably controlled, the operation contamination probability is reduced, the material consumption is reduced, the preparation time is shortened, and the working efficiency is improved. The common pulp refiner can be more convenient,the use convenience of the pulp refiner is kept, the use process is more convenient and rapider, the working efficiency and the cutting-up degree are improved, and too long preparation time and wasteof reagent consumables caused by human factors and equipment are reduced. The detachable handheld crusher does not need to be charged, and can be used at any time.

Owner:湖北省银丰鼎诚生物工程有限公司

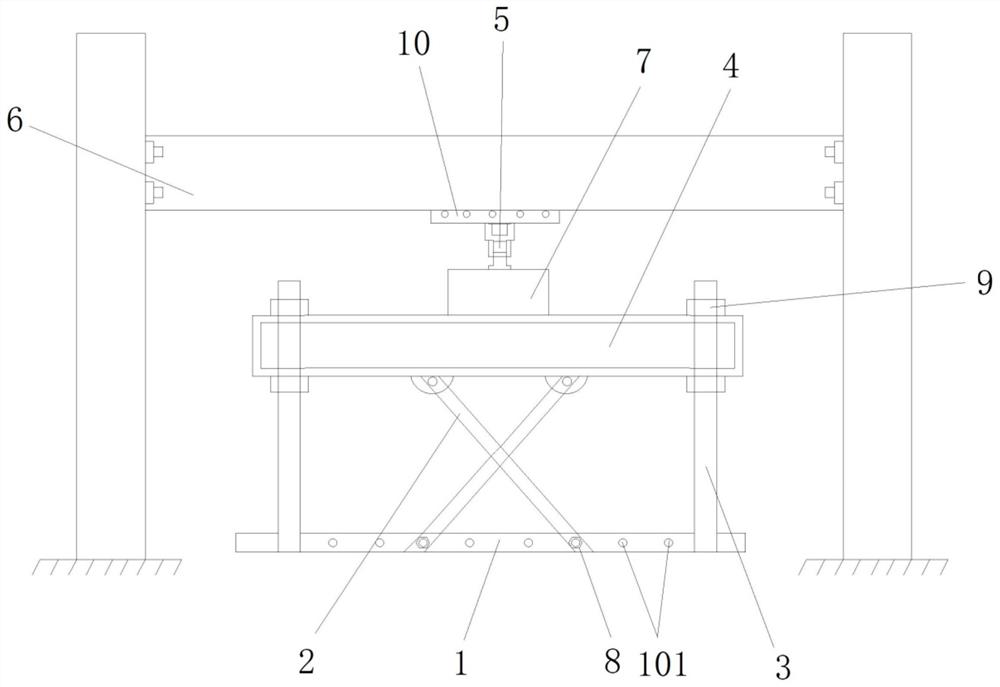

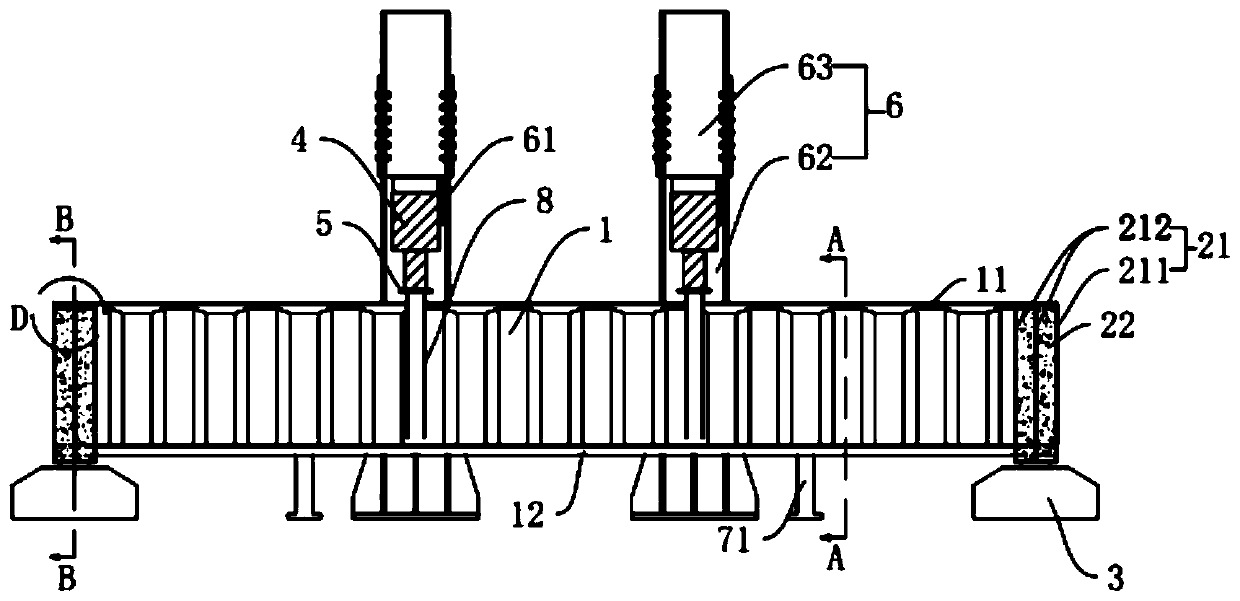

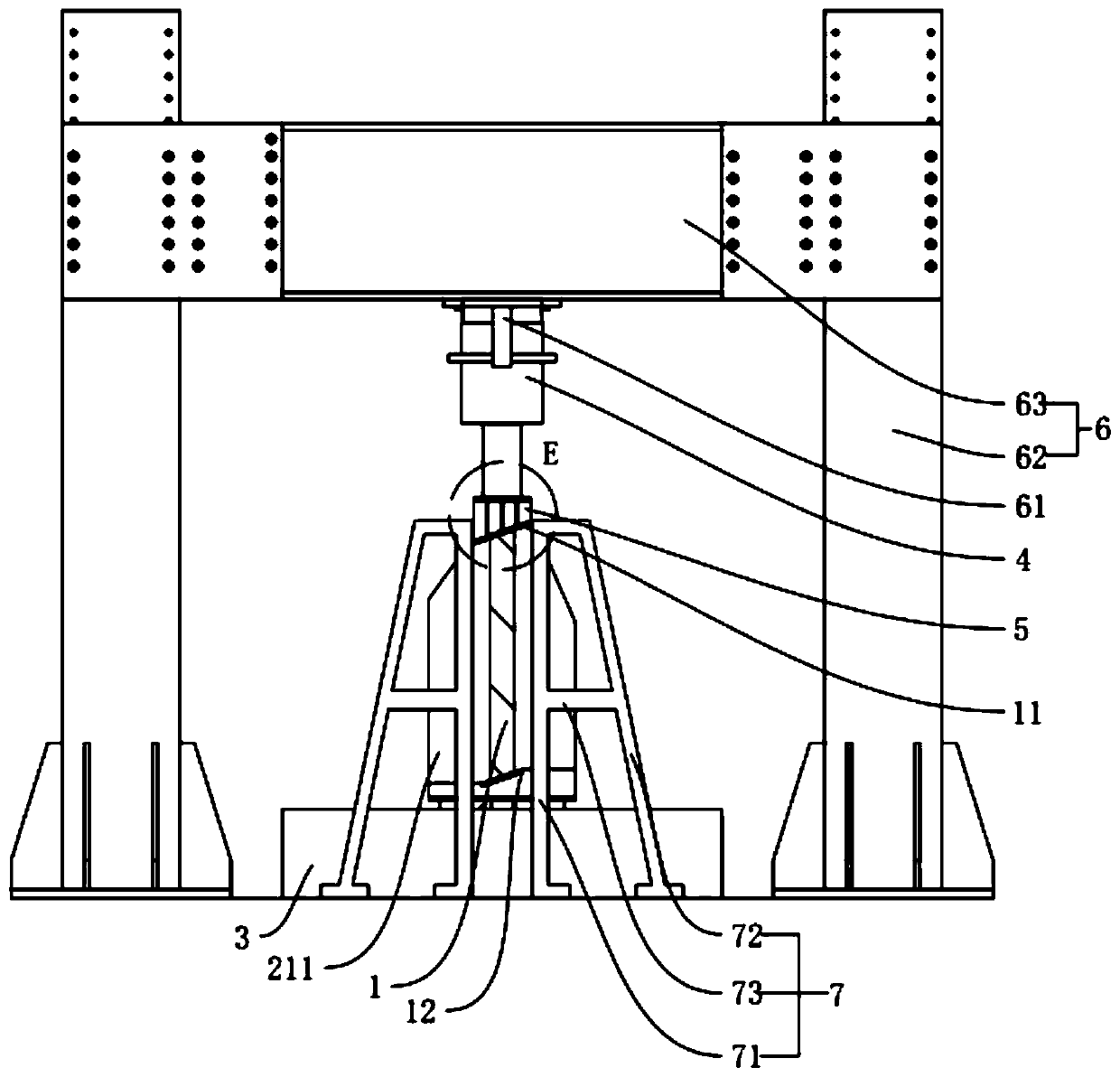

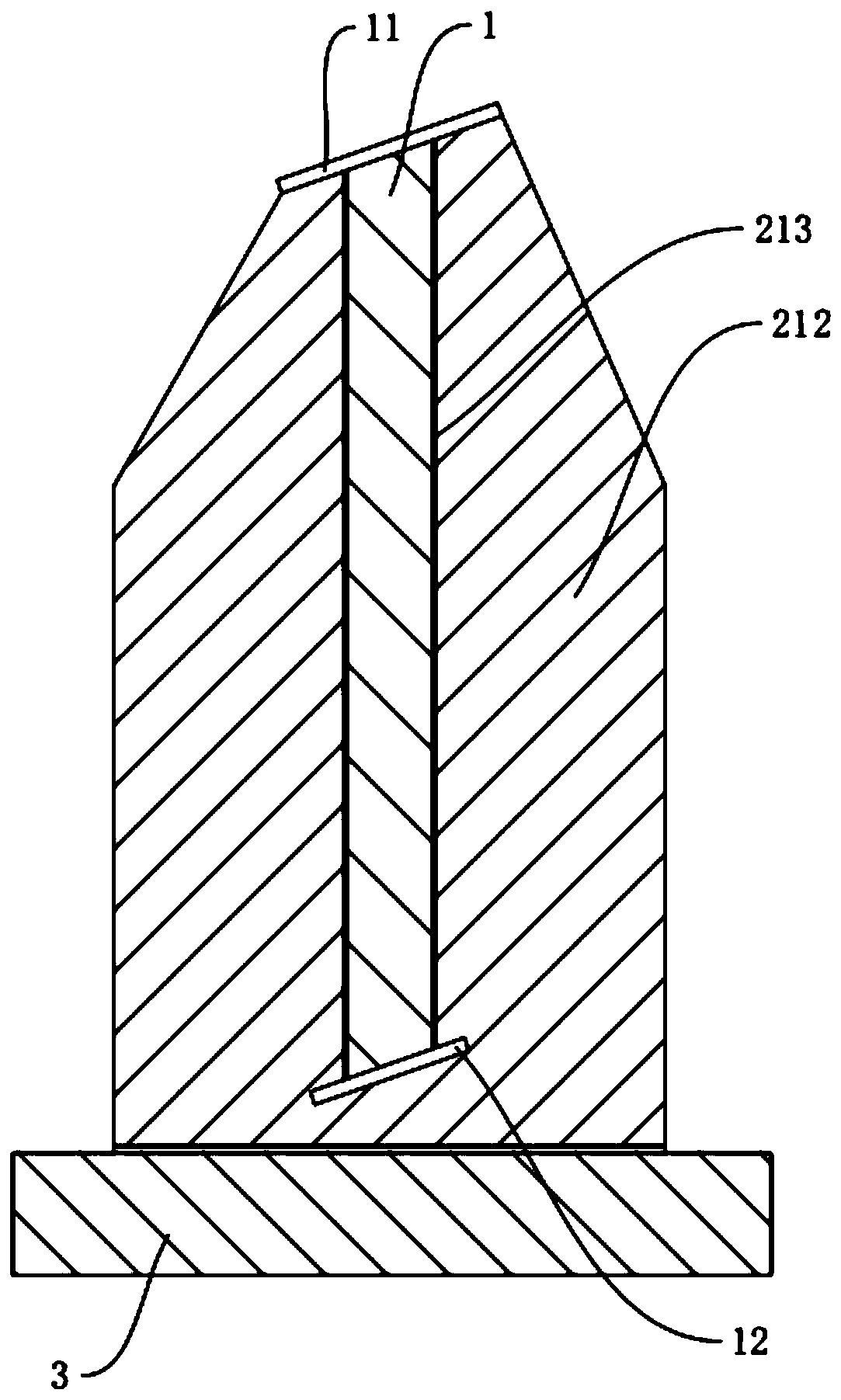

Low-cycle repeated loading test device

PendingCN112630004ALower the altitudeTo achieve the purpose of the testMaterial strength using repeated/pulsating forcesTrackwayStructural engineering

Owner:HAINAN UNIVERSITY

Steel box beam inclined web plate fatigue testing device

InactiveCN110044742ALower requirementReduce mistakesMaterial strength using repeated/pulsating forcesEngineeringRebar

The invention provides a steel box beam inclined web plate fatigue testing device, and belongs to the technical field of engineering detection. The steel box beam inclined web plate fatigue testing device comprises two groups of supporting components and loading components, the supporting components are arranged at two ends of an inclined web plate for supporting the inclined web plate and maintaining the inclined web plate at a vertical state, and the supporting components is filled with concrete to achieve a reinforcement function; the loading components are arranged above an upper wing plate for loading a vertical acting force to the upper wing plate so as to provide a loading force for a fatigue test of the inclined web plate, and the loading force is a component force of the loading force required in a full-scale test, so that the requirements for the loading equipment are reduced; and the loading force directly acts on the steel box beam inclined web plate, so that the obtained experimental result is more accurate than that in a scale test; and the steel box beam inclined web plate fatigue testing device provided by the invention is a novel testing device with lower requirements for loading equipment and less error.

Owner:XINGTAI ROAD & BRIDGE CONSTR GENERAL

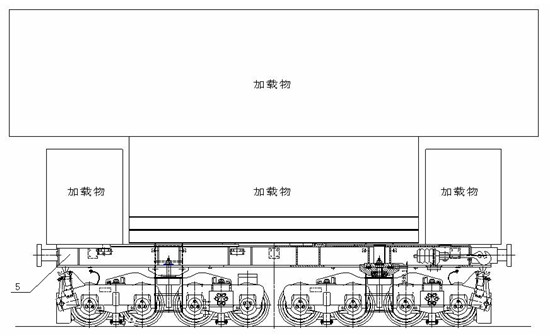

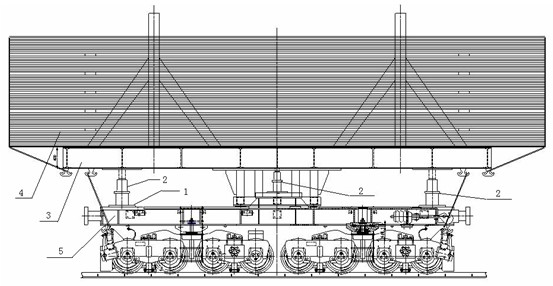

Railway vehicle loading test device and method

Owner:株洲新通铁路装备有限公司

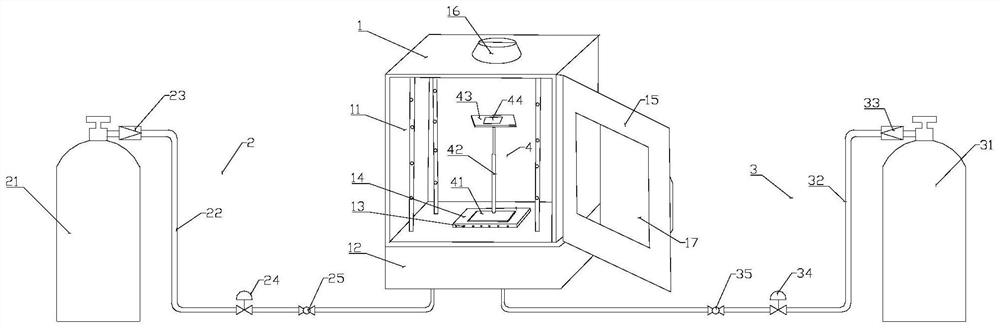

Combustion box capable of adjusting gas environment

PendingCN113588864AMeet the test requirementsImprove test accuracyChemical analysis using combustionThermodynamicsProcess engineering

The invention discloses a combustion box capable of adjusting a gas environment. And through the design of the box body, a relatively closed combustion environment can be realized. The top of the structure is provided with the exhaust port, mixed gas of nitrogen and oxygen is injected from bottom to top, and gas in the box body can be replaced in all directions before a combustion test, so that the gas environment in the combustion box meets test requirements. The gas proportion can be obtained by adjusting the nitrogen assembly and the oxygen assembly. The combustion box is suitable for combustion instruments, such as a cone calorimeter, of which the gas environment cannot be adjusted. When the combustion box is combined with a combustion instrument for use, the exhaust port can be used as an exhaust channel and can also be used as an ignition channel, and thermal load and electronic ignition of the combustion instrument can be completed through the exhaust port.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +2

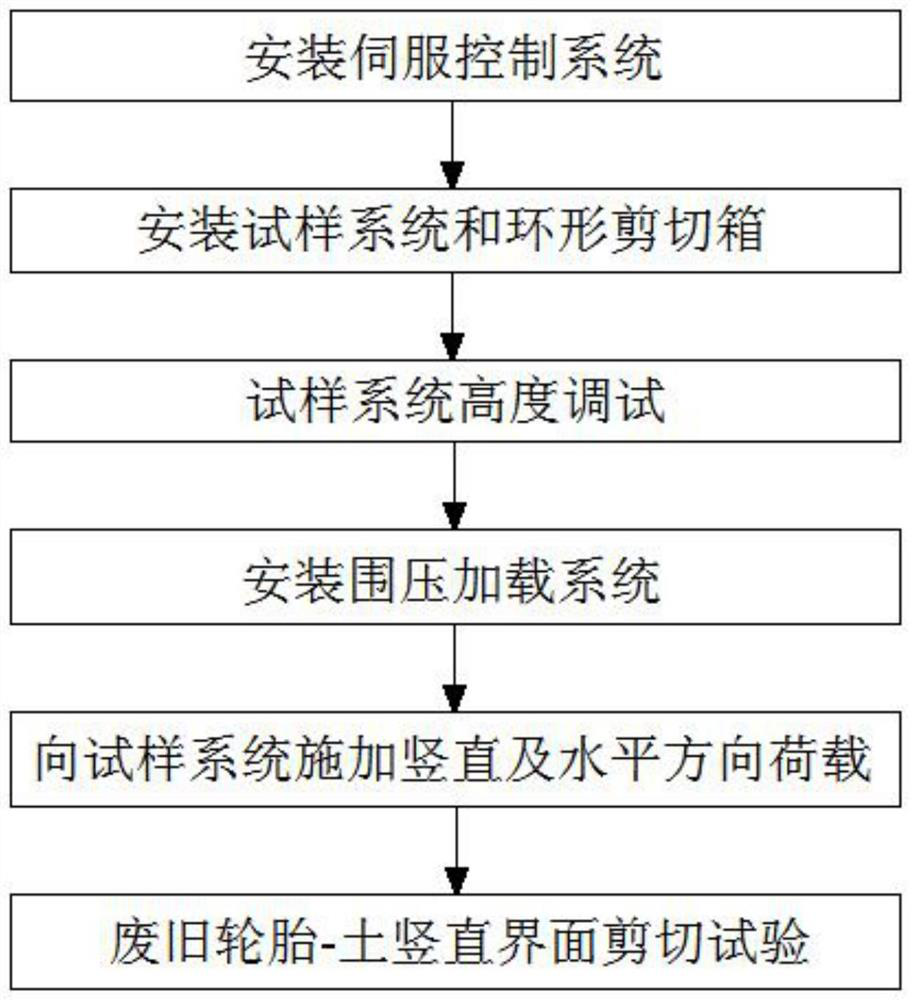

Waste tire-soil vertical interface shear characteristic testing method

PendingCN114166658AOvercoming the defects of shear mechanical propertiesMeet the test requirements for shear propertiesMaterial strength using steady shearing forcesWaste tiresServo

The invention discloses a waste tire-soil vertical interface shear characteristic test method, which comprises the following steps of: firstly, sequentially installing a servo control system, a sample system, a confining pressure loading system and a data acquisition system, filling a waste tire with a soil sample II, then installing the waste tire on a push-pull actuating rod, and loading the soil sample II on the push-pull actuating rod; a confining pressure air bag and a soil sample I are sequentially and annularly arranged in the annular shearing box from outside to inside, and the radial inner side face of the soil sample I makes contact with the outer side face of the waste tire; finally, horizontal and vertical loads are provided for the waste tire-soil vertical interface through a confining pressure air bag and a top spiral disc respectively, a hydraulic servo motor is started to apply stress to a push-pull actuating rod for a shear test, and shear mechanical parameters are calculated according to stress data obtained under different load conditions. The method provided by the invention is suitable for carrying out shear test on the waste tire-soil vertical interface under different burial depth and size conditions.

Owner:CHANGSHA UNIVERSITY

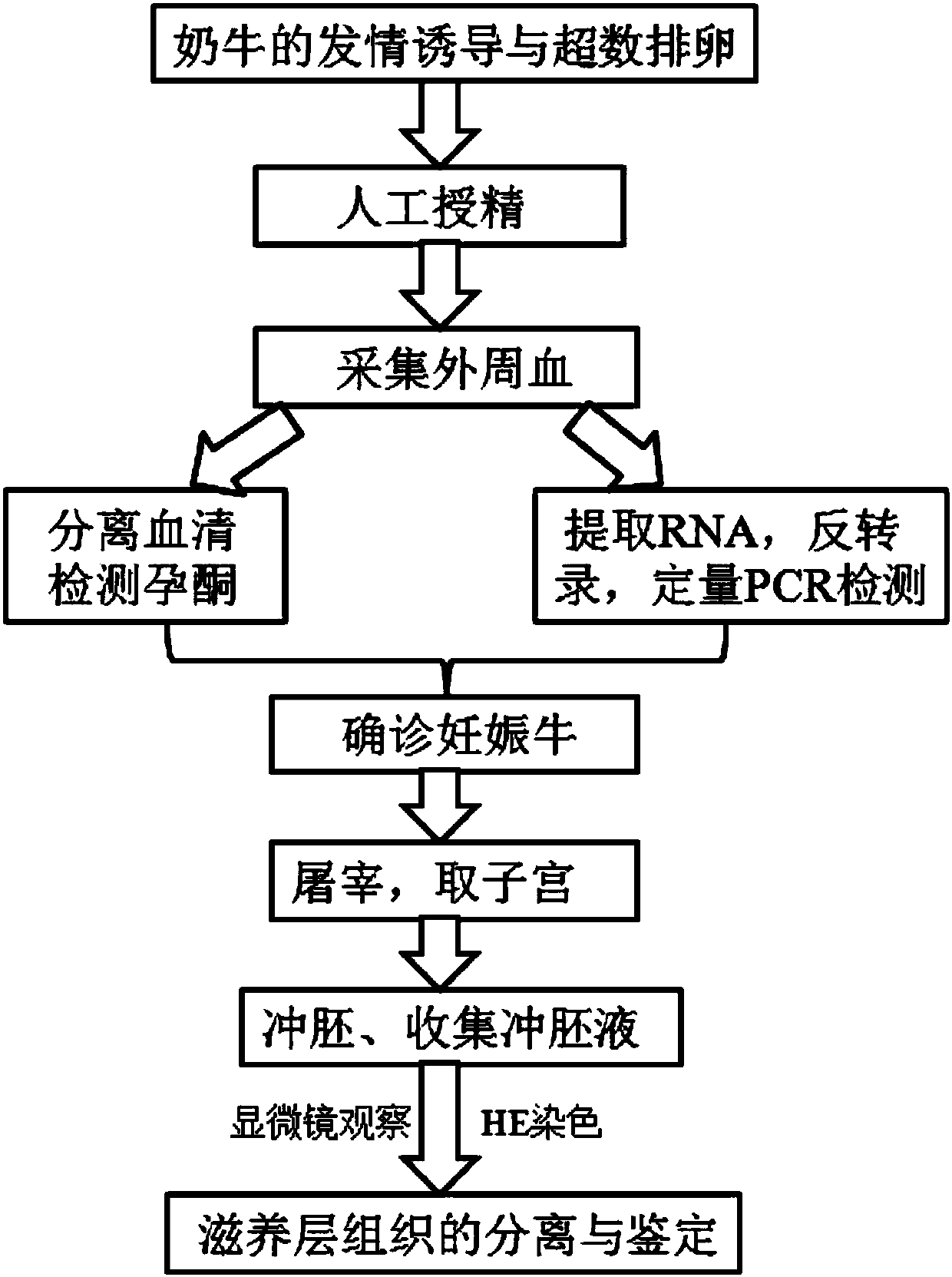

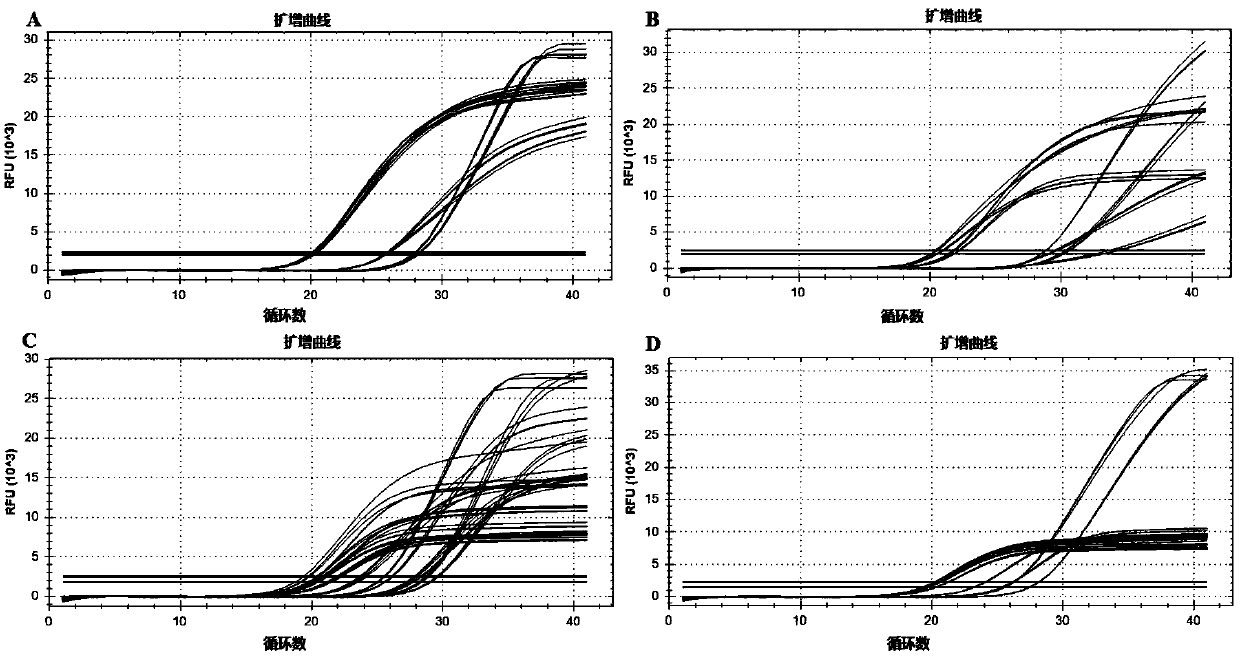

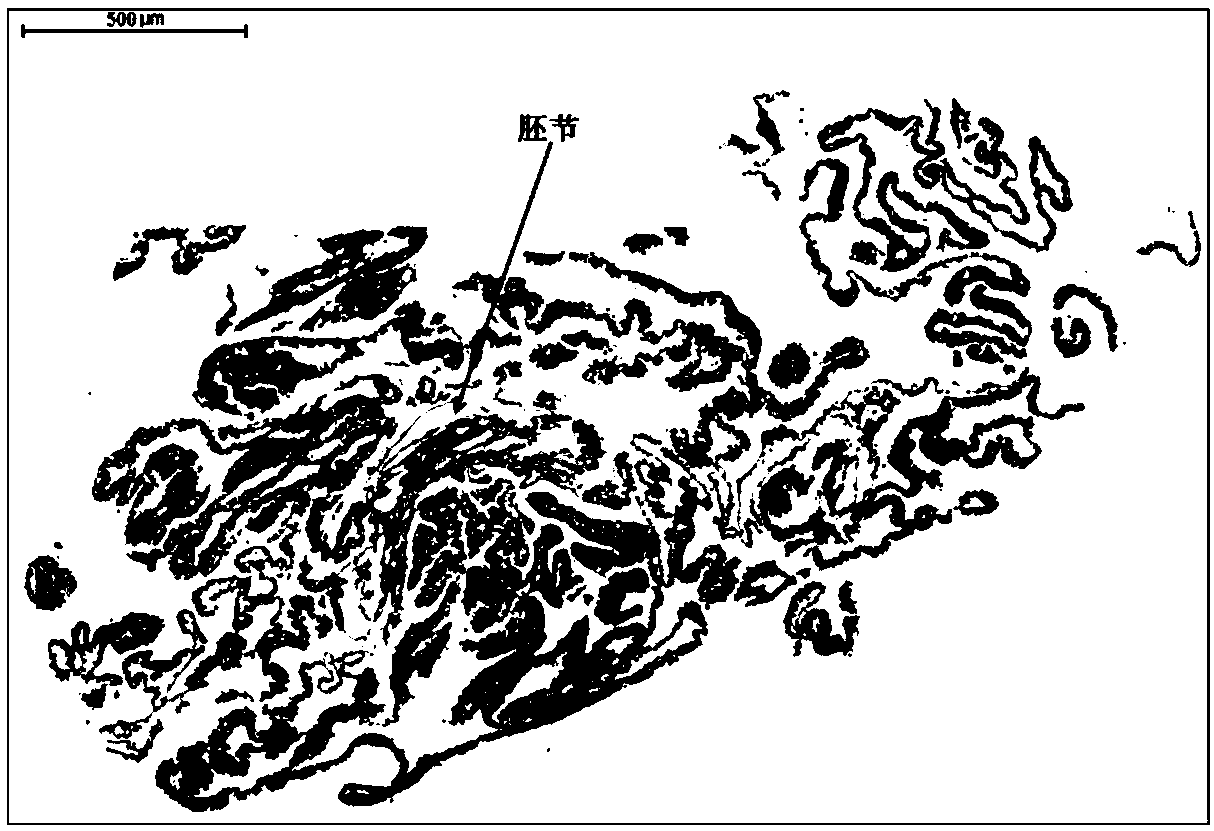

Bovine early embryo trophoblast tissue obtaining method

ActiveCN107723272AThe method is simple and fastCheap methodCell dissociation methodsAnimal reproductionGestationGynecology

Owner:WUHAN POLYTECHNIC UNIVERSITY

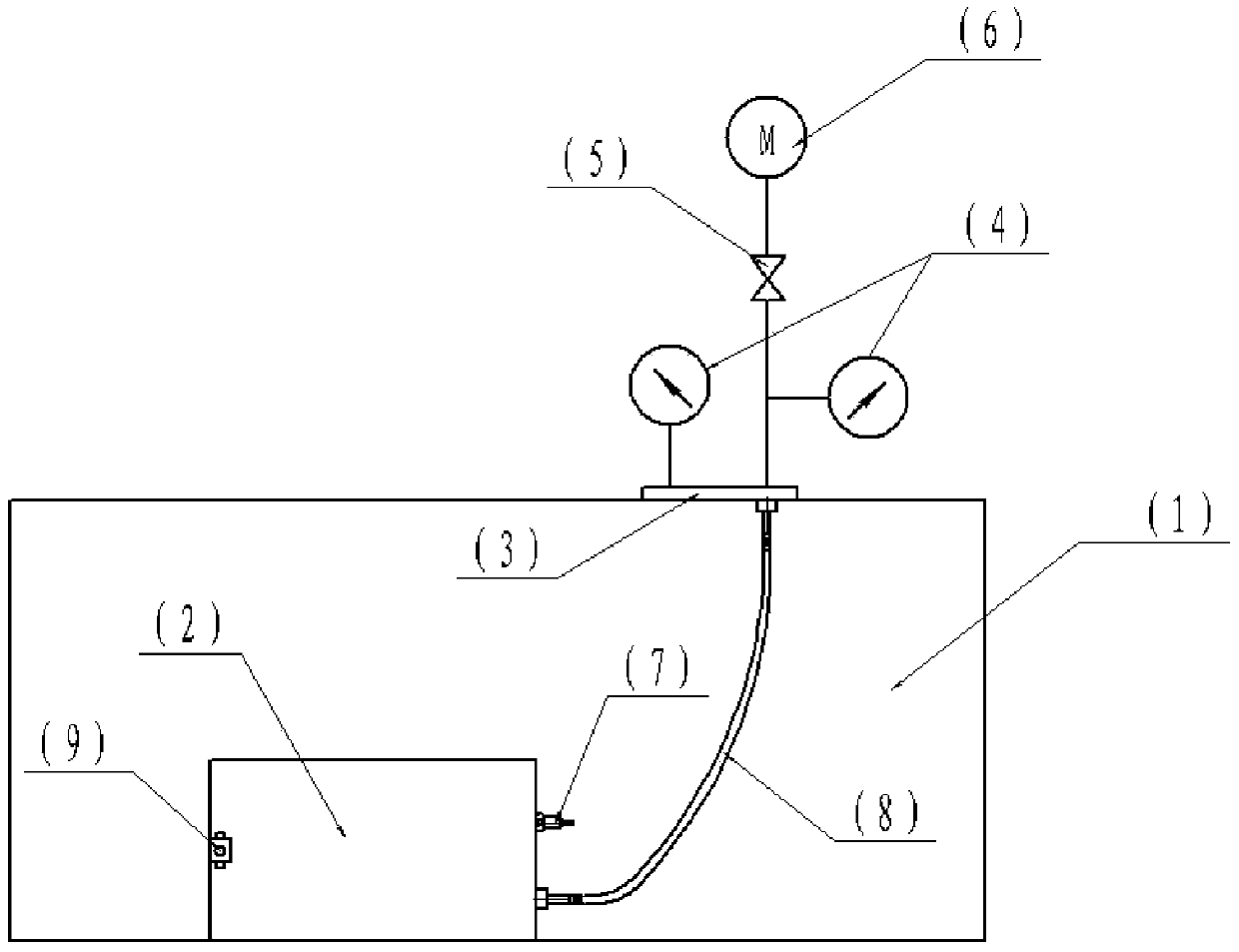

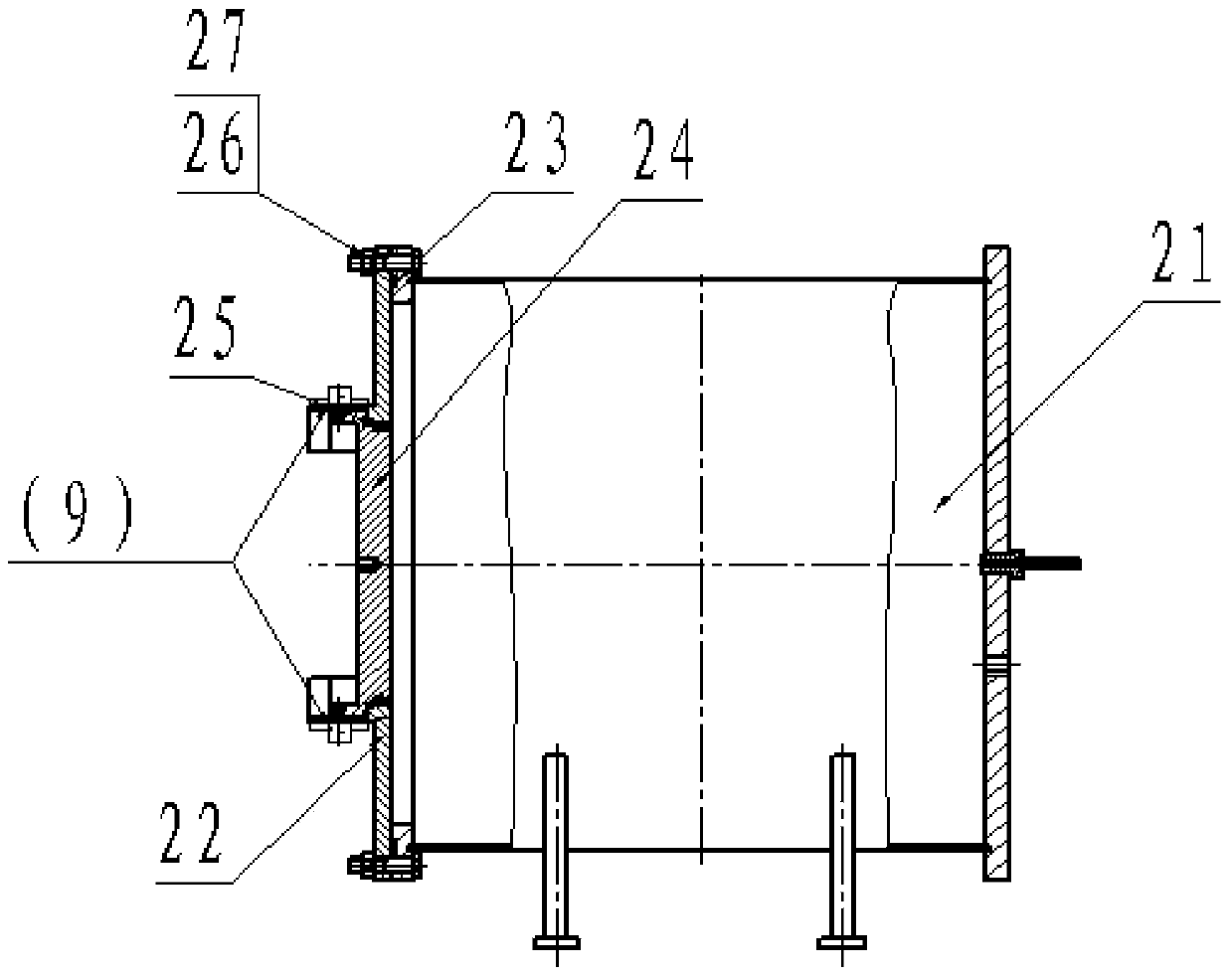

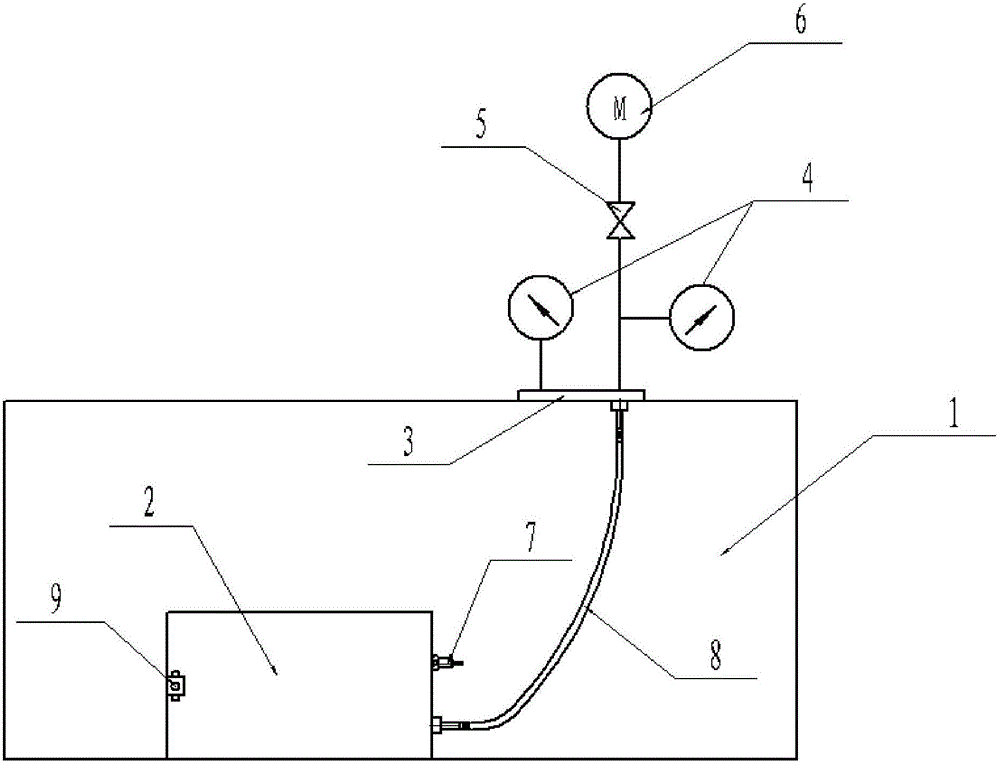

Rapid decompression test device

ActiveCN104198208ASimple methodTo achieve the purpose of the testStructural/machines measurementPistonBall valve

The invention relates to a rapid decompression test device comprising a thermal vacuum box (1), a container (2), a gas circuit connection system (3), negative pressure gauges (4), a ball valve (5), a vacuum pump (6), a negative pressure sensor (7), a connection hose (8) and a pin puller (9). The rapid decompression test device is characterized in that interior pressure of a test box is decreased to a specified pressure by pumping through the thermal vacuum box (1), the interior pressure of the container is decreased to the specified pressure by pumping through the vacuum pump (6), a piston on the container is unlocked with the pin puller (9) which runs quickly and highly synchronously, and the piston is opened by the interior and exterior pressure difference so as to allow rapid decompression.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

A rapid decompression test device

ActiveCN104198208BSimple methodTo achieve the purpose of the testStructural/machines measurementDifferential pressureEngineering

The invention relates to a rapid decompression test device comprising a thermal vacuum box (1), a container (2), a gas circuit connection system (3), negative pressure gauges (4), a ball valve (5), a vacuum pump (6), a negative pressure sensor (7), a connection hose (8) and a pin puller (9). The rapid decompression test device is characterized in that interior pressure of a test box is decreased to a specified pressure by pumping through the thermal vacuum box (1), the interior pressure of the container is decreased to the specified pressure by pumping through the vacuum pump (6), a piston on the container is unlocked with the pin puller (9) which runs quickly and highly synchronously, and the piston is opened by the interior and exterior pressure difference so as to allow rapid decompression.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

A Driving Mechanism Used on Cable Endurance Test Bench

The invention discloses a driving mechanism used on a dragline endurance test platform. The driving mechanism comprises a supporting frame, a turnplate which is connected with the supporting frame in a rotation manner through a first rotor shaft, a mounting hole which is formed in the turnplate and is used for connecting one end part of a drive rod, a motor and a speed reducer for driving the first rotor shaft to rotate, a sliding block fixedly connected with the other end part of the drive rod, a guide rail arranged on the supporting frame, a dragline mounting rack fixedly connected with the sliding block as well as a driving optical shaft arranged on the dragline mounting rack, wherein the mounting hole is deviated from the first rotor shaft, and the sliding block is arranged on the slide guide in a sliding manner; the sliding direction of the sliding block is perpendicular to an axial line direction of the first rotor shaft, the motor drives the turnplate to rotate, and then the drive rod is arranged in the mounting hole of the deviation rotating center; the drive rod can do reciprocating linear motion, and the drive rod drives the sliding block do reciprocating linear motion and further drives the dragline mounting rack to do reciprocating linear motion; therefore, the purpose of a test is achieved, the structure is simple, the use is safe, and a test effect is better.

Owner:金新民

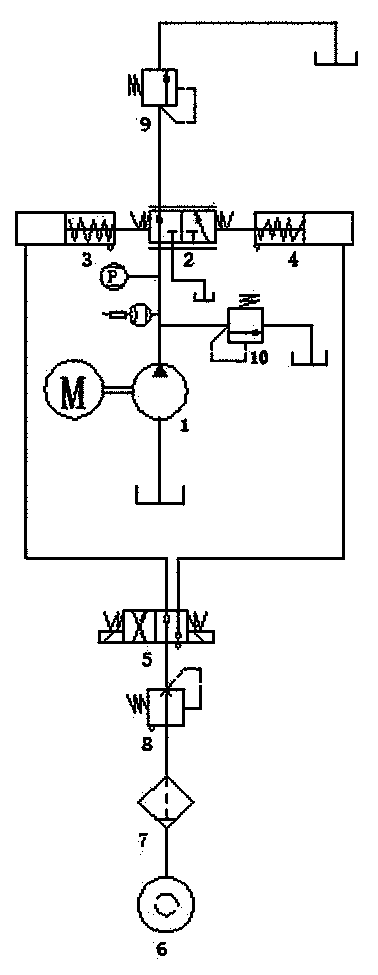

Hydraulic pump impact test pressure instantaneous variation device and method

InactiveCN109185116AQuick switchQuick pressurePump testingPositive-displacement liquid enginesHydraulic pumpEngineering

The invention belongs to the technical field of hydraulic pump impact tests, and particularly relates to a hydraulic pump impact test pressure instantaneous variation device and method. The hydraulicpump impact test pressure instantaneous variation device comprises a tested hydraulic pump, a first reversing valve and a pneumatic reversing mechanism, the tested hydraulic pump communicates with thefirst reversing valve, the pneumatic reversing mechanism is connected with the first reversing valve, and moving of a valve element of the first reversing valve can be achieved through the pneumaticreversing mechanism. Moving of the valve element of the first reversing valve can be achieved through the pneumatic reversing mechanism, and the instantaneous reversing purpose is achieved. An air cylinder piston rod moves at the final instantaneous speed to impact a valve element of the reserving valve, and the instantaneous action is achieved. Back-and-forth reversing is achieved through the actions of two air cylinders, and the test purpose is achieved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

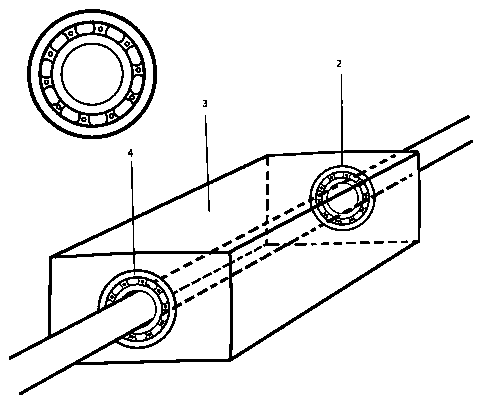

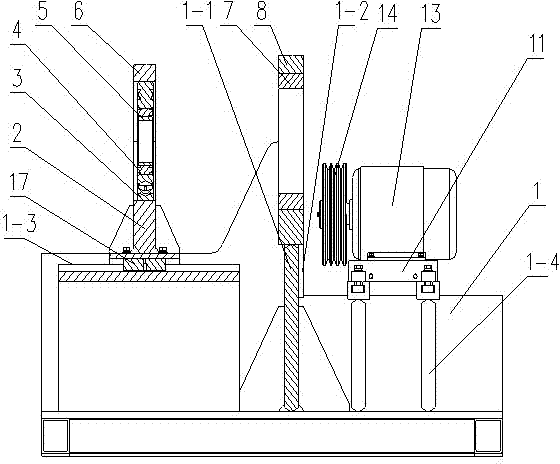

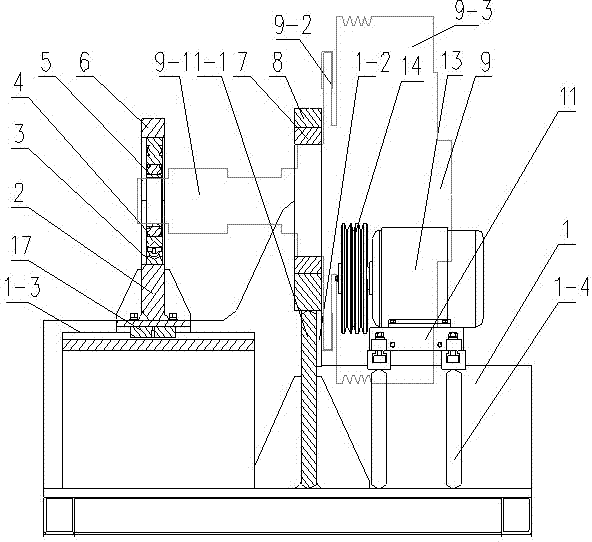

Common mechanical press wet-type clutch universal test tooling

InactiveCN103335839BNo frequent replacementTo achieve the purpose of the testMachine gearing/transmission testingEngineeringSlide plate

The invention discloses a common mechanical press wet-type clutch universal test tooling. A bearing and an upper cover II are mounted on a support, an upper cover I is mounted on a big support plate, two T-shaped grooves II are formed in a platform, the support is mounted on the platform, and an expansion sleeve and an adjusting sleeve are sequentially mounted on the inner side of the bearing on the support; a big bushing is further mounted on the inner side of the big support plate, and a panel is welded in the contact position of the lower part in front of the big support plate and a flywheel seat; two small support plates are arranged in front of the big support plate, each small support plate is provided with a T-shaped groove I, a motor pulling plate and two motor sliding plates are mounted between the two small support plates, the motor pulling plate and the motor sliding plates are mounted on the small support plates, the motor pulling plate and the motor sliding plates adjacent to the motor pulling plate are connected together through two adjusting screw rods, and a motor is mounted on the two motor sliding plates. According to the invention, tests can be performed on various types of mechanical press wet-type clutches, and the tooling is not needed to be replaced frequently due to different types of the mechanical press wet-type clutches.

Owner:JIANGSU XUZHOU METALFORMING MACHINE GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com