Rapid decompression test device

A test device and rapid decompression technology, applied in the direction of measuring device, machine/structural component test, instrument, etc., can solve the problem that the vacuum pump is difficult to realize, and achieve the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

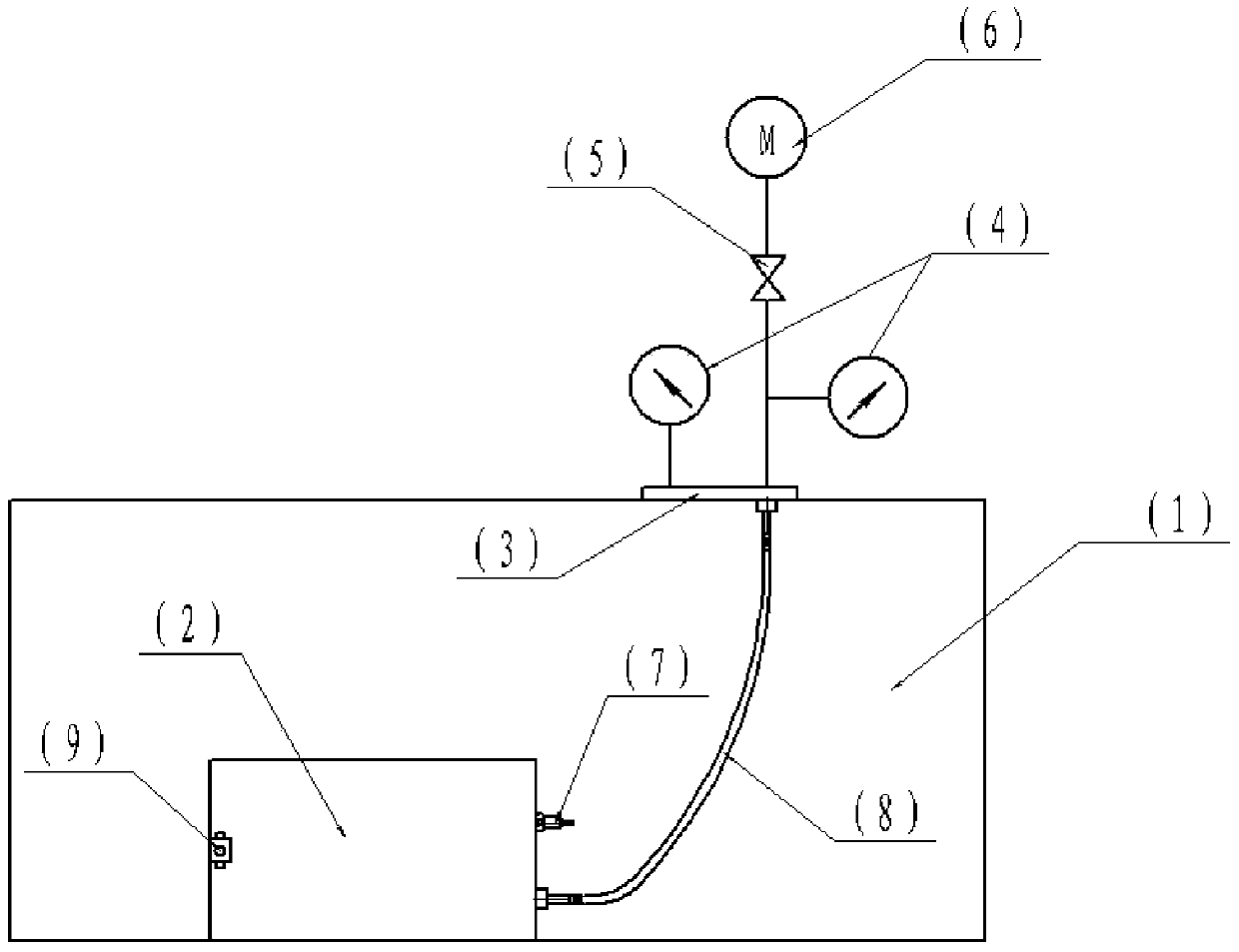

[0014] (1) First, the volume V of the container used for the test should be determined according to the size of the test product A , that is, the container must have enough space to place the product.

[0015] (2) After determining the volume of the container and the thermal vacuum box, according to the gas pressure before and after the test, use the formula PV=nRT to determine the initial pressure of the thermal vacuum box. Assume that the pressure of the thermal vacuum box in the initial state is P B , with volume V B , the temperature is T B , the container pressure is P A , with volume V A ,T A , the pressure of the gas after equilibrium is P, and the temperature in the container is T A ', the temperature outside the container is T B ', where P A , V B , P known, V A ,T A ,T B ,T B 'Can be set by yourself, you can use the formula Calculate T B ', and then through the formula P B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com