Multifunctional visual research device for bentonite hydraulic power and air pressure splitting features

A bentonite and multifunctional technology, which is applied in the field of multifunctional visual bentonite hydraulic and pneumatic splitting characteristics research device, can solve the problems of difficult splitting, single function, poor scalability, etc., and achieve low price, simple operation and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

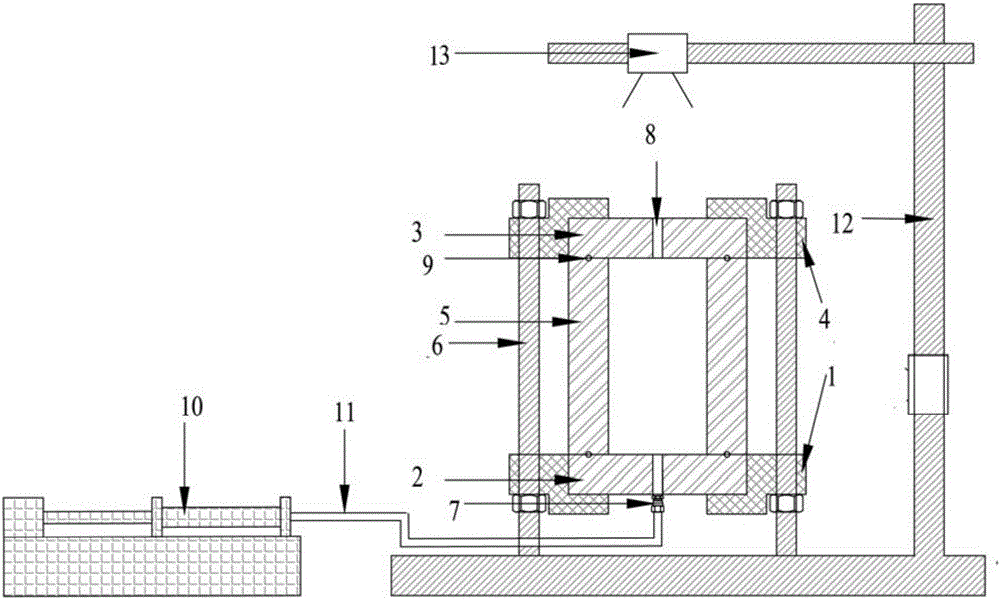

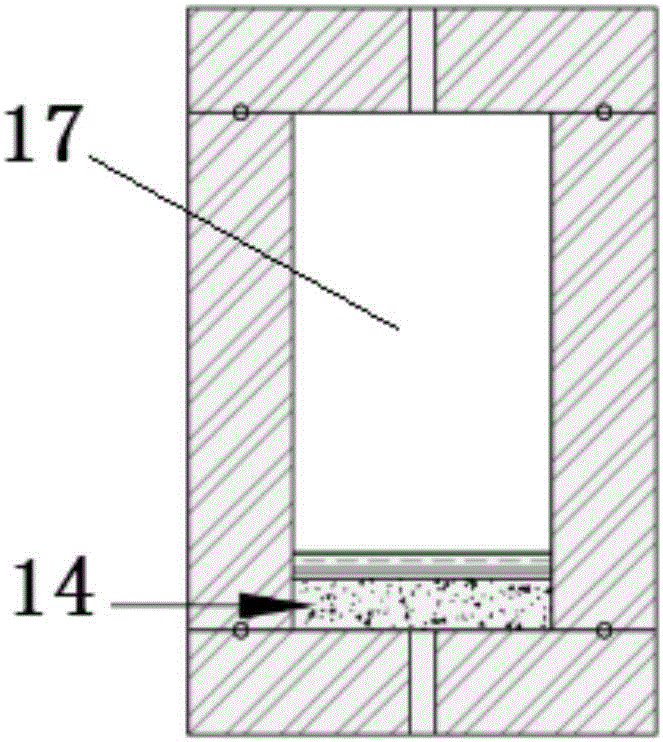

[0035] A multifunctional and visualized high-compacted bentonite hydraulic and air pressure splitting characteristics research device, its structure is as follows figure 1 As shown, it is used to determine the splitting characteristics of round cake-shaped high-compacted bentonite under uniform pressure at the bottom. The device includes a pressurized space, a water injection control component and a data acquisition component connected with the pressurized space. The pressure space includes a transparent top cover, a sleeve 5, and a transparent base sequentially connected from bottom to top, wherein the structures of the transparent top cover and the transparent base are as follows: image 3 with Figure 4 As shown, the transparent top cover includes a plexiglass top cover 3 in the center and a stainless steel top cover 4 fixedly connected to the outside of the plexiglass top cover 3. The center of the plexiglass top cover 3 is provided with an air vent 8, and the stainless s...

Embodiment 2

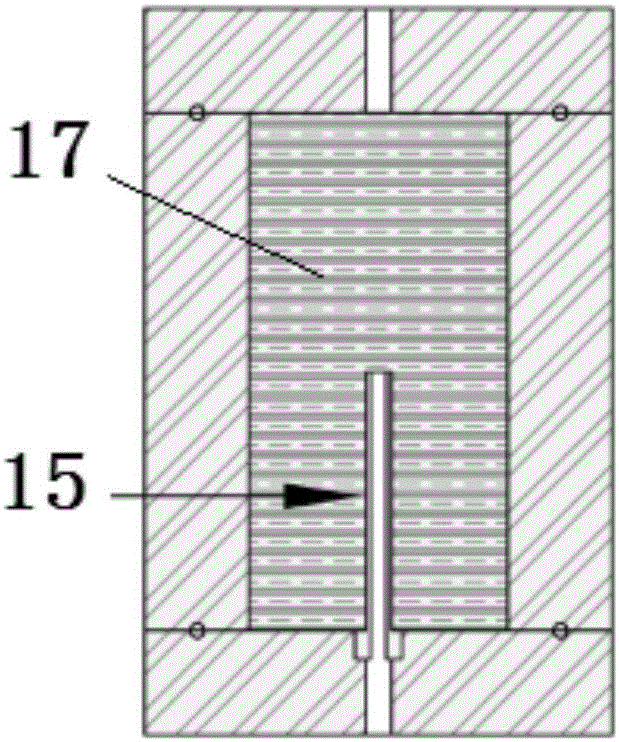

[0039] Adopt the research device identical with embodiment 1, difference is:

[0040]The water injection needle 15 is installed on the transparent base and communicated with the interface. The bentonite 17 to be tested has a height of 100 mm and a diameter of 50 mm, and the bottom of the bentonite 17 to be tested is artificially drilled to obtain a hole with a diameter of 50 mm and a length of 50 mm. During installation, apply epoxy resin to the side wall of the water injection needle 15 to ensure contact with the bentonite 17 to be tested. After curing for 24 hours, install the instrument and start the water injection splitting test.

Embodiment 3

[0042] Adopt the research device identical with embodiment 2, difference is:

[0043] In this embodiment, a glass block 16 is also filled above the bentonite 17 to be tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com