Method for gasification and compression of crushed coal

A crushed coal pressurized gasification and coal gas technology, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of large carbon dioxide emissions, large water vapor consumption, and large energy consumption, so as to reduce CO2 emissions and reduce The effect of water vapor consumption and lower yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

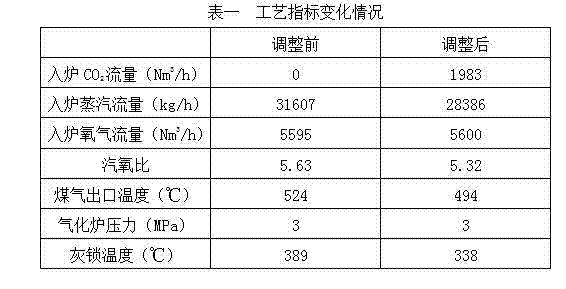

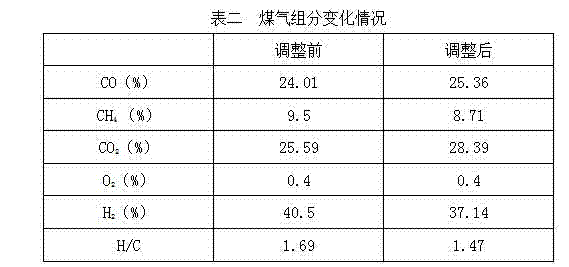

Embodiment 1

[0044] A pressurized gasification method for pulverized coal. Under pressurized conditions, the raw coal is gasified into crude gas through the reverse continuous contact reaction between the gasification agent and the raw coal. The gasification agent is composed of carbon dioxide, water vapor and pure oxygen. The weight ratio of carbon dioxide, water vapor and pure oxygen is 0.47:3.4:1, the gasification reaction pressure is 3MPa, and the volume percentage of each component of crude gas is CO 22%-27%, CH 4 7%-9%, CO 2 26%-30%, O 2 0.2%-0.4%, H 2 35.5%-38.5%.

Embodiment 2

[0046] A pressurized gasification method for pulverized coal. Under pressurized conditions, the raw coal is gasified into crude gas through the reverse continuous contact reaction between the gasification agent and the raw coal. The gasification agent is composed of carbon dioxide, water vapor and pure oxygen. The weight ratio of carbon dioxide, water vapor and pure oxygen is 0.4:3.6:1, the gasification reaction pressure is 3MPa; the volume percentage of each component of crude gas is CO 22%-27%, CH 4 7%-9%, CO 2 26%-30%, O 2 0.2%-0.4%, H 2 35.5%-38.5%.

Embodiment 3

[0048]A pressurized gasification method for pulverized coal. Under pressurized conditions, the raw coal is gasified into crude gas through the reverse continuous contact reaction between the gasification agent and the raw coal. The gasification agent is composed of carbon dioxide and water vapor and pure oxygen. The weight ratio of carbon dioxide, water vapor and pure oxygen is 0.52:3.2:1, the gasification reaction pressure is 3MPa; the volume percentage of each component of crude gas is CO 22%-27%, CH 4 7%-9%, CO 2 26%-30%, O 2 0.2%-0.4%, H 2 35.5%-38.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com