Waste tire-soil vertical interface shear characteristic testing device

A technology for testing waste tires and characteristics, applied in the field of reinforced soil engineering, can solve problems such as inability to realize, inability to realize vertical interface shear test, and inability to reflect the shear mechanical properties of waste tires and soil cylinders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

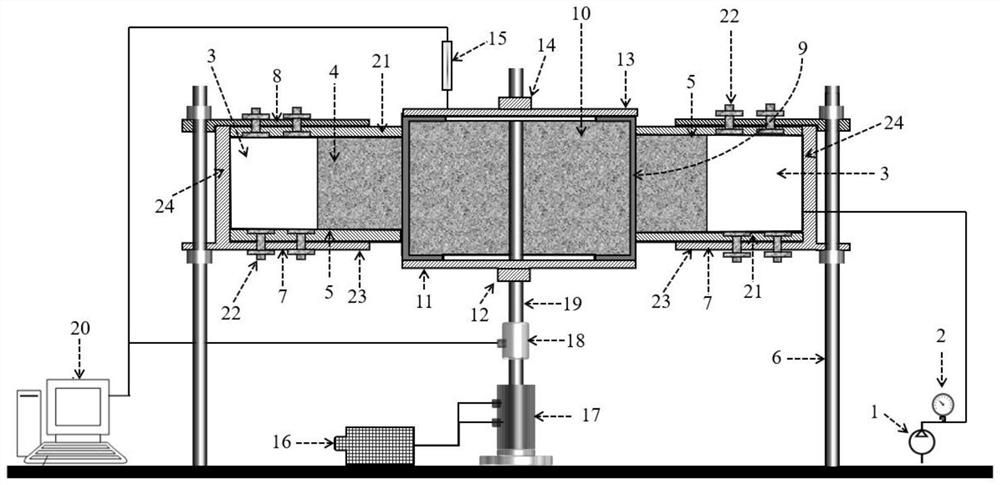

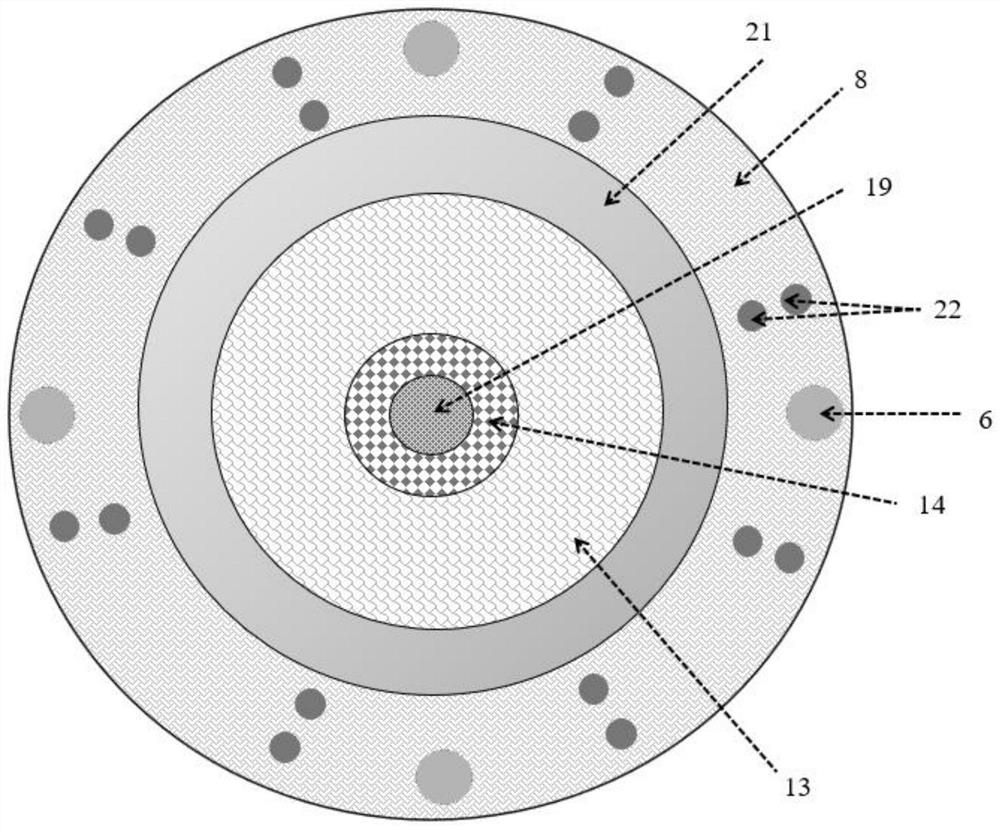

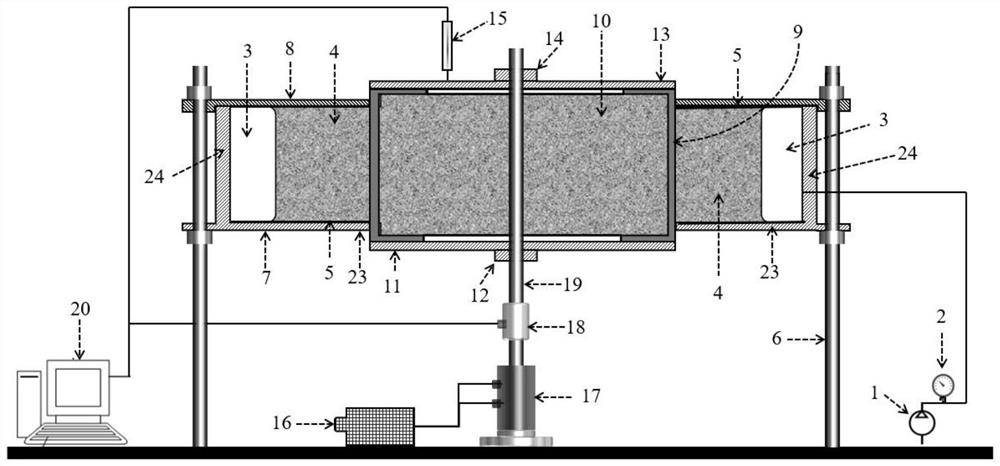

[0036] see figure 1 with figure 2 , a waste tire-soil vertical interface shear characteristic testing device, including a sample system, a confining pressure loading system, a servo control system and a data acquisition system.

[0037]The sample system includes waste tires 9 , an actuating platform base 11 and an actuating platform top cover 13 . The waste tire 9 is arranged horizontally, the top cover 13 and the base 11 of the actuator are opposite up and down and are located on the lower surface and the upper surface of the waste tire 9 respectively, and the base 11 and the top cover of the actuator are 13 are all in close contact with the surface of waste tires, and soil sample II 10 is uniformly filled inside the waste tires 9 . The actuating table in this application is divided into a base and a top cover structure that can act independently, which can meet the testing requirements of waste tires with different tread widths.

[0038] In this embodiment, the diameters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cohesion | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com