Detachable handheld crusher

A crusher and hand-held technology, applied in the field of laboratory equipment, can solve the problems of inconvenient cleaning of equipment, increased pollution, expensive consumables, etc., and achieve the effects of reducing material costs and preparation time, improving work efficiency, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

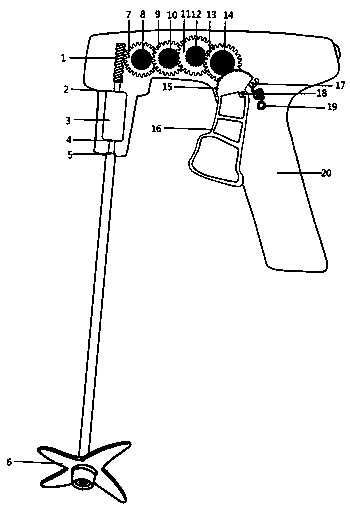

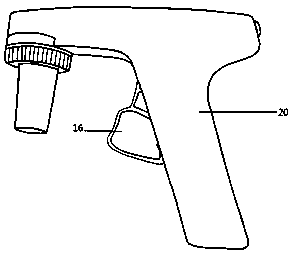

[0036] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It can be seen that the detachable handheld crusher of the present invention is composed of a handheld device 20, a rotating device 6, and a base 21 thereof;

[0037] The rotating device 6 is mainly composed of a stainless steel tube and a stainless steel rotating blade fixed by a stainless steel nut;

[0038] The material of the handheld device 20 and the base 21 is PP;

[0039] The tension spring 19 is made of low manganese spring steel (65Mn);

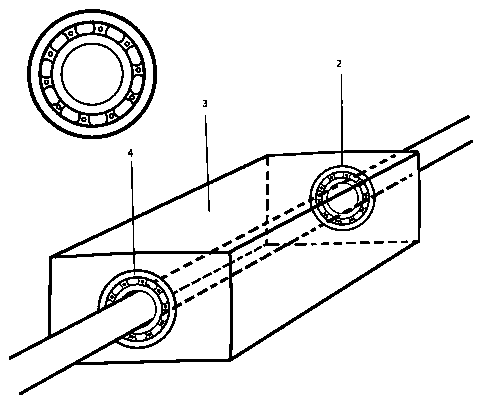

[0040] The turbine fixing device 3 is made of PP material;

[0041] Bearings 2 and 4 are made of bearing steel (GCR15);

[0042] The starting gear 15, the stretching hook 17, the starting device 16 and the fixing nut 18 are made of polyphenylene sulfide (PPS);

[0043] Turbine device 1, gears 7, 8, 9, 10, 11, 12, 13, 14 and gear fixing devices are all made of PPS;

[0044] The contact part 5 between the lower end of the turbine device 1 and the rotating devi...

specific Embodiment 3

[0048] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It can be seen that the working steps of the detachable handheld crusher are as follows:

[0049] Step 1: Start: The detachable handheld crusher holds the handle of the handheld device by hand, and presses the starting device with the strength of the hand to drive the starting gear connected to the starting device;

[0050] Step 2: Transmission: The starting gear drives the eighth gear to rotate, the eighth gear and the seventh gear are fixed on the handheld device through nuts, the eighth gear drives the seventh gear, the seventh gear drives the sixth gear, the sixth gear and the The fifth gear is fixed on the handheld device through a nut, the rotation of the sixth gear drives the fifth gear to rotate, the rotation of the fifth gear drives the rotation of the fourth gear, the fourth gear and the third gear are fixed on the handheld device through a nut, and the fourth gear rotates Drive the third gear to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com