Indoor test simulation device and method for pipe pulling and jacking construction

An indoor test and simulation device technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of complex grouting conduit layout, etc., and achieve the effect of reasonable structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

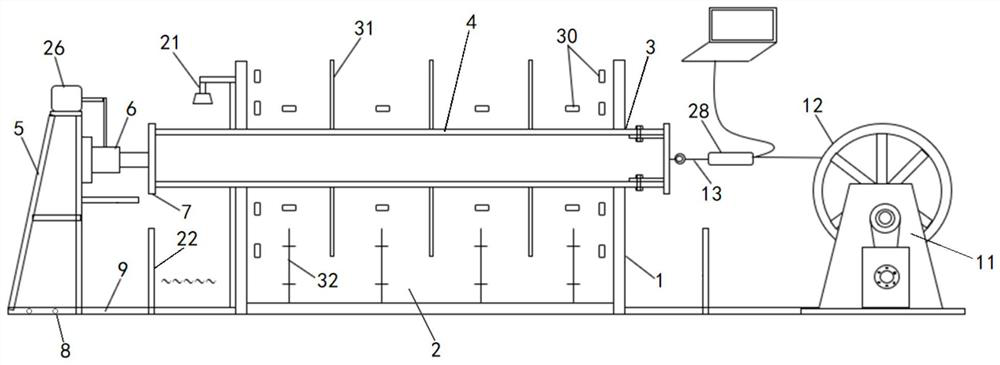

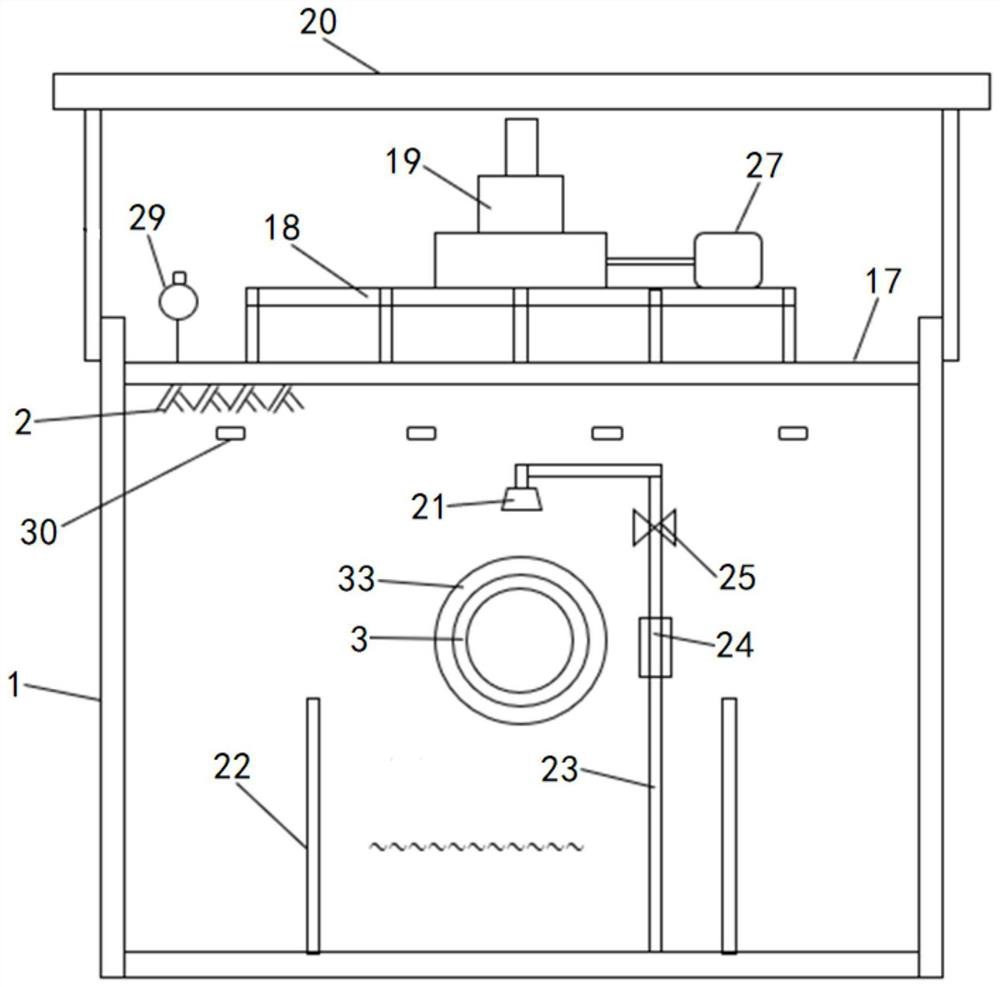

[0037] Such as figure 1 , figure 2 As shown, Embodiment 1 of the present invention provides a kind of indoor test simulation device of jacking pipe construction, comprises box body 1, and its top surface is opened and arranged, and vertical loading mechanism is arranged above, through vertical loading mechanism to box body The test soil 2 placed in 1 applies a vertical load. The two opposite sides of the box body 1 are provided with a circular top hole 3, and a simulated pipe 4 for simulating construction pipe jacking is inserted in the circular top hole 3, and the two ends of the simulated pipe 4 can pass through the circular top holes on both sides 3. One of the circular top holes 3 is provided with a grouting assembly, and the outer surface of the simulated pipeline 4 is sprayed during the loading process, so that the outer wall of the simulated pipeline 4 is covered with a layer of lubricating mud. A horizontal loading mechanism is provided on the outside of the circul...

Embodiment 2

[0046] Embodiment 2 of the present invention provides a kind of indoor test simulation method of jacking pipe construction, adopts the simulation device that embodiment 1 provides, comprises the following steps:

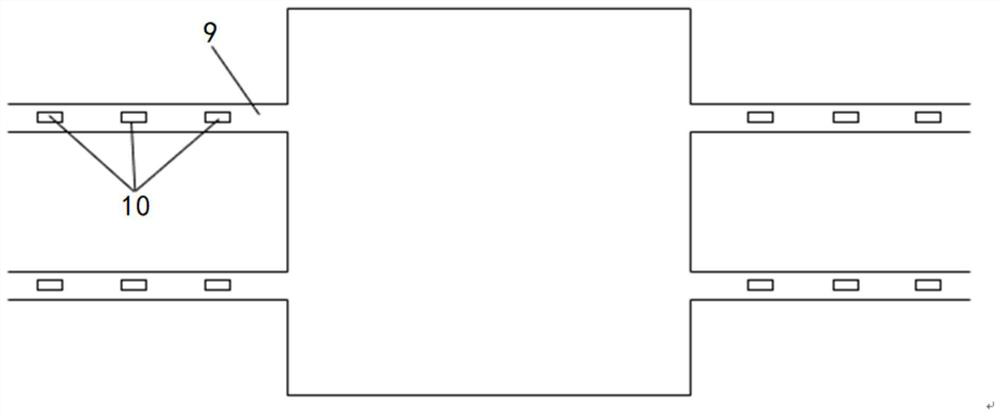

[0047] Step 1. According to the test requirements, fill the test soil 2 into the box 1 in layers and compact it. During the filling process, the earth pressure cell 30, the inclinometer 31 and the displacement sensor 32 are installed accordingly. The inclinometer tube 31 is installed vertically, the earth pressure cell 30 is installed in the soil below the rigid loading plate 17, in the soil near the side wall of the box body 1 and in the soil around the simulated pipe 4, and the displacement sensor 32 adopts a magnetic The telescopic linear displacement sensor is composed of a measuring rod, an electronic compartment and a non-contact magnetic ring set on the measuring rod. Before filling the soil, the measuring rod is vertically placed on the bottom plate of the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com