Tobacco leaf composition and application for reducing cigarette irritation

A irritating and compositional technology, which is applied in the fields of application, tobacco, and tobacco preparation, can solve problems such as insecurity, and achieve the effects of reducing the use effect, increasing the aroma, and reducing the irritation of cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

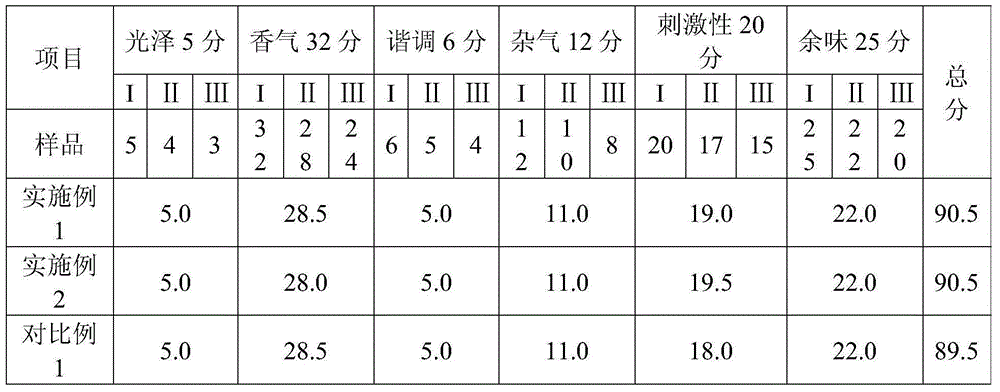

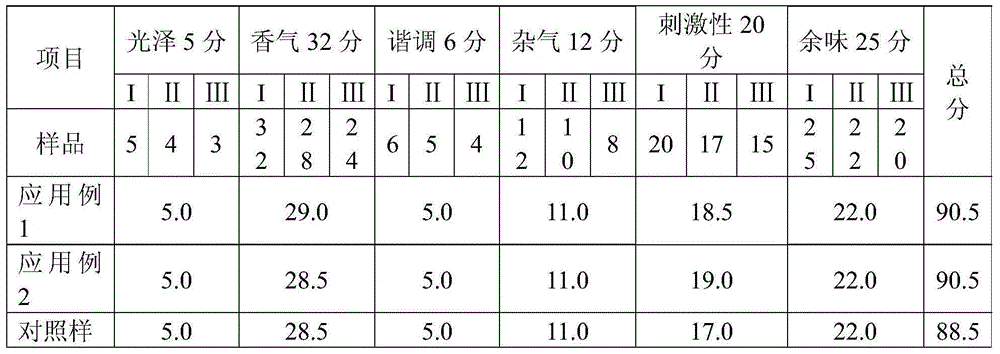

Embodiment 1

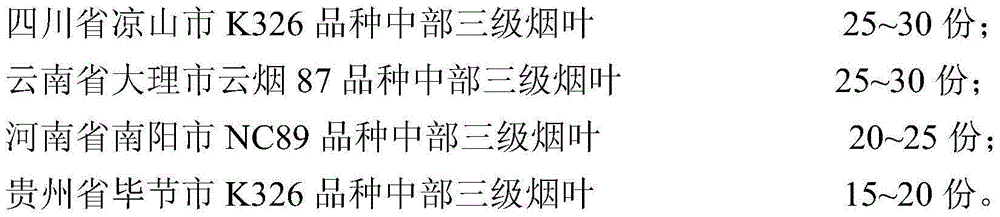

[0036] Take 300 grams of third-grade tobacco leaves in the middle of the K326 variety in Liangshan City, Sichuan Province with a malic acid content of 3.18%, oxalic acid content of 1.15%, linolenic acid content of 0.25%, and malonic acid content of 0.28%; malic acid content of 3.56%, oxalic acid content of 1.32%, and linolenic acid content Content 0.31%, malonic acid content 0.21% 250 grams of third-grade tobacco leaves in the middle of Yunyan 87 variety in Dali City, Yunnan Province; malic acid content 3.21%, oxalic acid content 1.22%, linolenic acid content 0.26%, malonic acid content 0.25% Nanyang, Henan Province 250 grams of third-grade tobacco leaves in the middle part of the NC89 variety in the city; 150 grams of third-grade tobacco leaves in the middle part of the K326 variety in Bijie City, Guizhou Province. The tobacco leaves are cut into shreds and mixed evenly to prepare the tobacco leaf composition reducing the irritation of cigarettes.

Embodiment 2

[0038]Take 3.25% malic acid content, 1.21% oxalic acid content, 0.34% linolenic acid content, 0.12% malonic acid content 250 grams of third-grade tobacco leaves in the middle of the K326 variety in Liangshan City, Sichuan Province; 3.37% malic acid content, 1.18% oxalic acid content, linolenic acid content Content 0.25%, malonic acid content 0.16% 300 grams of third-grade tobacco leaves in the middle of Yunyan 87 variety in Dali City, Yunnan Province; malic acid content 3.17%, oxalic acid content 1.51%, linolenic acid content 0.27%, malonic acid content 0.15% Nanyang, Henan Province 200 grams of third-grade tobacco leaves in the middle part of the NC89 variety in the city; the content of malic acid is 3.35%, the content of oxalic acid is 1.35%, the content of linolenic acid is 0.25%, and the content of malonic acid is 0.09%. The tobacco leaves are cut into shreds and mixed evenly to prepare the tobacco leaf composition reducing the irritation of cigarettes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com