Steam box pre-decompression device and method

The technology of a pressure relief device and a steamer, which is applied to steam cooking utensils, cooking utensils, household appliances, etc., can solve the problems of human body burns and increased humidity in the kitchen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

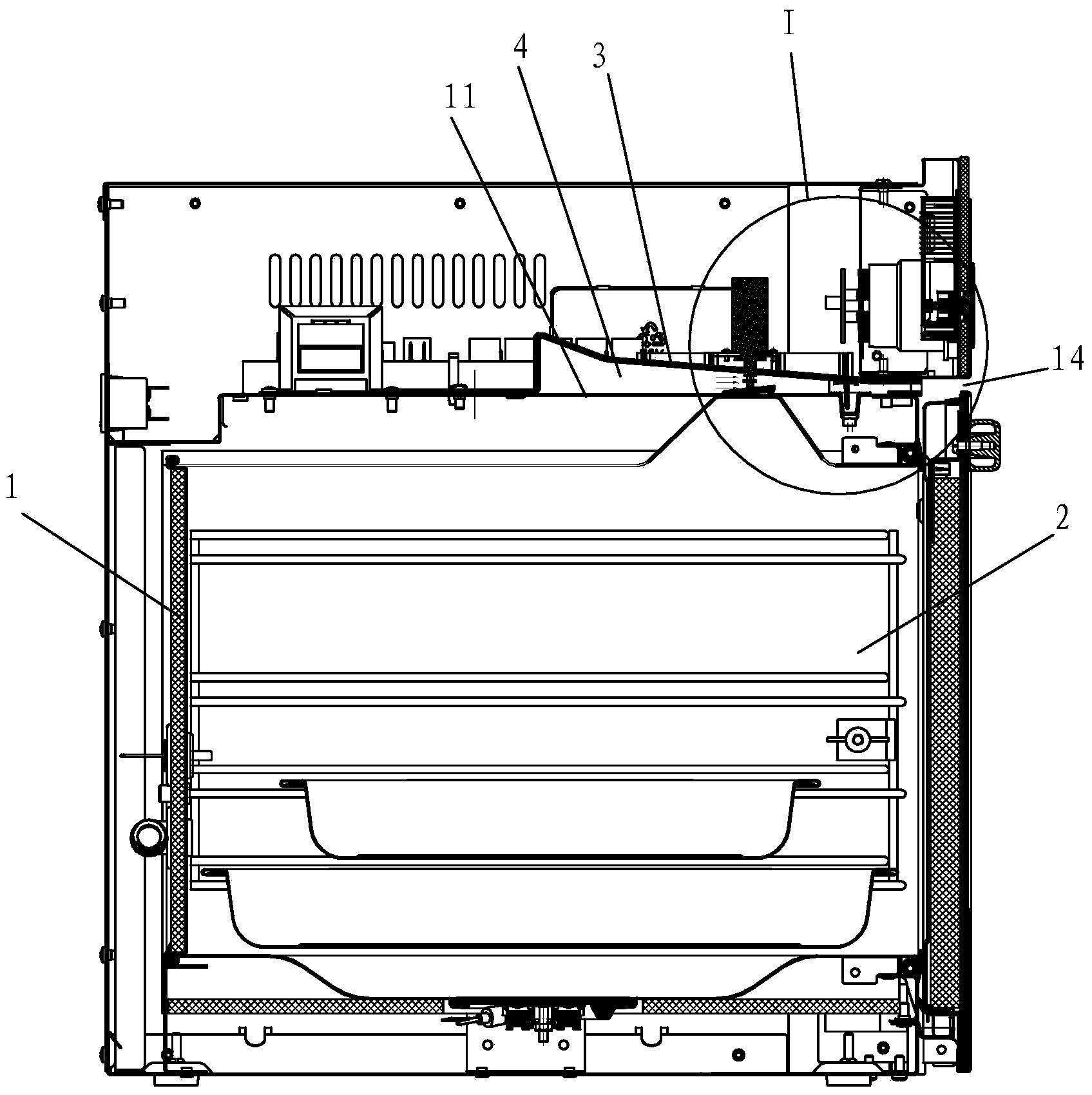

[0025] Such as figure 1 The steam box shown includes an inner container assembly 1. The inner container of the inner container assembly 1 is the internal steaming cavity 2 of the entire container. The upper part of the inner container assembly 1 is an upper mounting plate 11, and a wind deflector is arranged above the upper mounting plate 11 3. An air duct 4 is formed between the upper mounting plate 11 and the wind deflector 3, the inlet of the aforementioned air duct is connected with the outlet of the inertial flow fan of the whole box, and the steam box is provided with an outlet communicating with the aforementioned air duct outlet 12 The tuyere 14, the steam box also includes a computer controller (not shown in the figure).

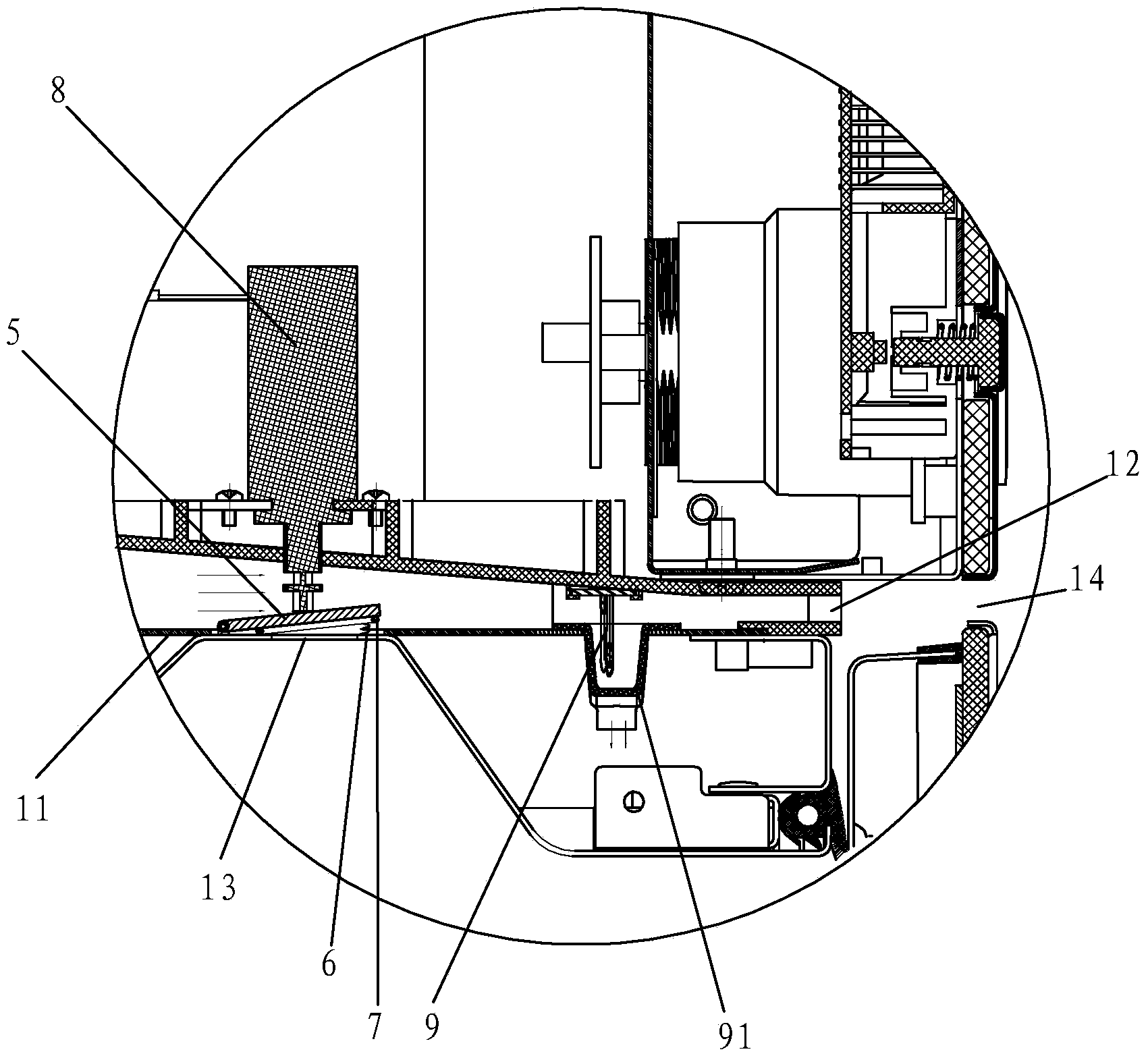

[0026] The steam box pressure relief device in advance includes the following structure, see figure 2 Shown:

[0027] A steam outlet 13 is opened on the aforementioned upper mounting plate 11,

[0028] A baffle 5 is movably arranged at the steam outlet ...

Embodiment 2

[0034] The difference from the first embodiment is that a pressure sensor is arranged inside the steam box, and the output end of the pressure sensor is connected to the computer controller. After the computer controller detects that the output value of the pressure sensor is greater than the first set value, the same Output a control signal to the power unit, and start the power unit to drive the baffle to move from the aforementioned steam outlet, so that the steam in the internal steaming cavity is discharged from the steam outlet in advance; and the computer controller detects that the output value of the pressure sensor is small After the second setting value, the control signal is also output to the power assembly to activate the power assembly to drive the baffle to cover the aforementioned steam outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com