Decompression device for device capable of detaching straw fibers in oriented mode and decompression method

A straw fiber and decompression technology, applied in the field of decompression devices, can solve the problems of uncontrollable moisture content of straw, difficult steam pressure value, wear and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

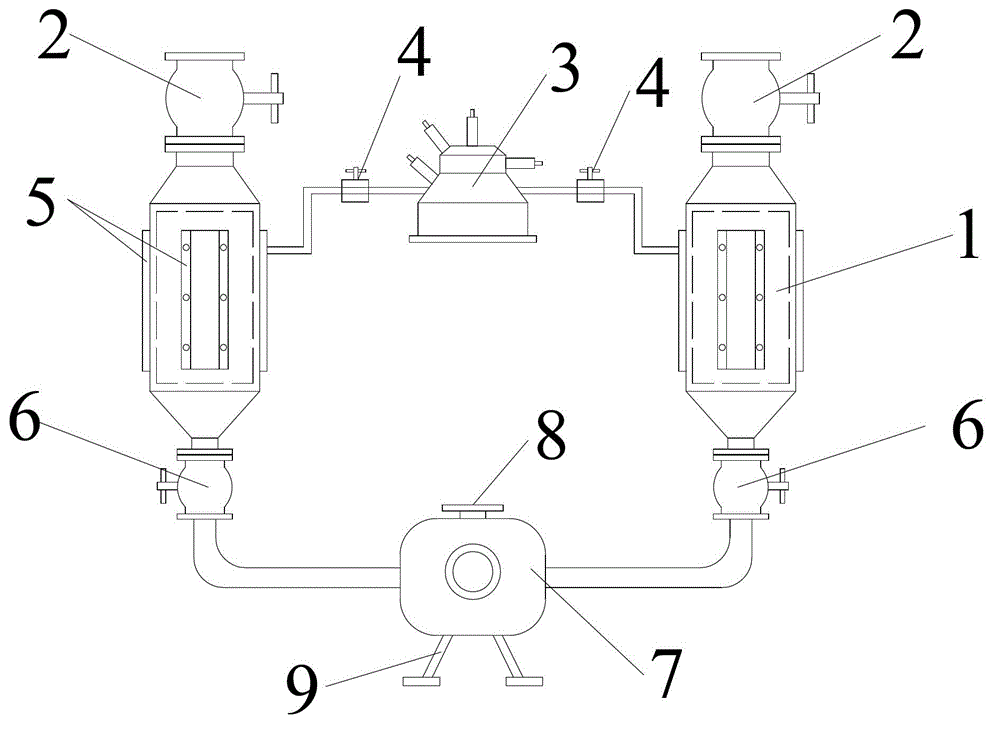

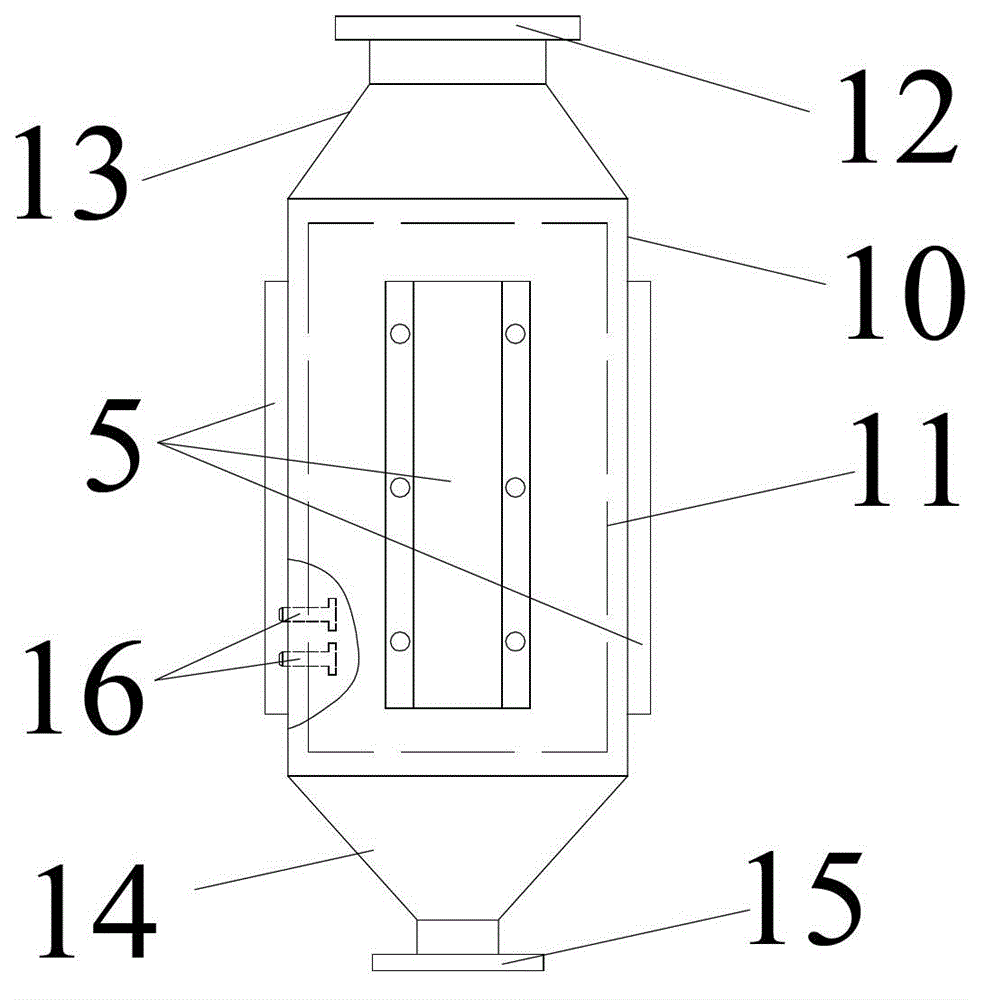

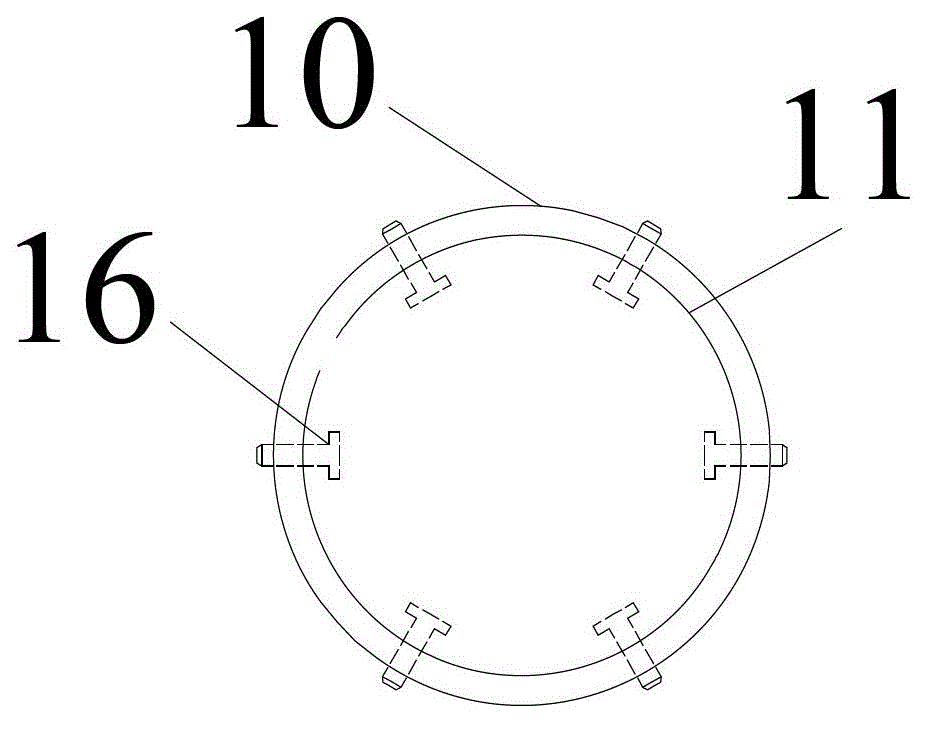

[0051] Such as figure 1 Shown is a directional dismantling straw fiber equipment, which includes a dismantling tank 1, an air compressor 3, a fiber expansion chamber 7, a decompression discharge valve 6, a feeding valve 2, a superheated steam generator 5 and a control system. The system is a PLC control system, the control system is connected with the decanter 1, the air compressor 3, the fiber expansion bin 7, the decompression discharge valve 6, and the superheated steam generator 5, and the control system forms a logical control relationship with each component of the dismantling equipment , to ensure that all institutions of the system work in an orderly manner in accordance with the instructions.

[0052] When the equipment is working, the straw that needs to be dismantled enters the dismantling tank 1 from the feeding valve 2, and the dismantling tank 1 is used to pretreat the biomass straw, providing necessary conditions for the subsequent expansion phase transition of ...

Embodiment 2

[0084] Application of decompression device on eccentric valve.

[0085] Since the valve is a self-selected sealing part for equipment users, this device is suitable for the needs of users in the paper industry. The decompression device can be fixed on the eccentric valve on the top, and the control button is turned on. The DC excitation motor rotates. At this time, the eccentric valve is controlled by the quick opening module and will automatically close. For eccentric valves, the spherical surface of the valve core in the eccentric valve will gradually advance along the valve seat. Because the valve has a shearing function, it can effectively meet the needs of the fiber not clogged and worn after the straw is disassembled; when the valve is closed, the sprocket is also driving The friction clutch drives the input shaft of the worm gear reducer to rotate together, and the output shaft of the reducer drives the quartering pawl turntable 24 to rotate, and the ratchet 22 is pushed...

Embodiment 3

[0087] Application of decompression device on ball valve.

[0088] As the biomass fiber ethanol industry generally uses ball valves as the sealing parts of steam explosion equipment, this device can also be installed and fixed on the ball valve, and the control button is also turned on to rotate the DC excitation motor. At this time, the ball valve is controlled by the quick opening module and will automatically close the spherical valve. When the spool and the valve are closed, the sprocket is also driving the friction clutch, and then drives the input shaft of the worm gear reducer to rotate together, and the output shaft of the reducer drives the quartering pawl turntable 24 to rotate, and the ratchet 22 is pushed by the pawl Do clockwise rotation until the rotation arc locks itself. At this time, the double tension spring 191 with the same core has stored energy, and the DC excitation motor stops rotating; then open another control button, the 30r / min deceleration motor, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com