Decompression device

一种减压装置、蒸气压缩的技术,应用在阀装置、阀的吸收流体能量的装置、照明和加热设备等方向,达到抑制噪声产生的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

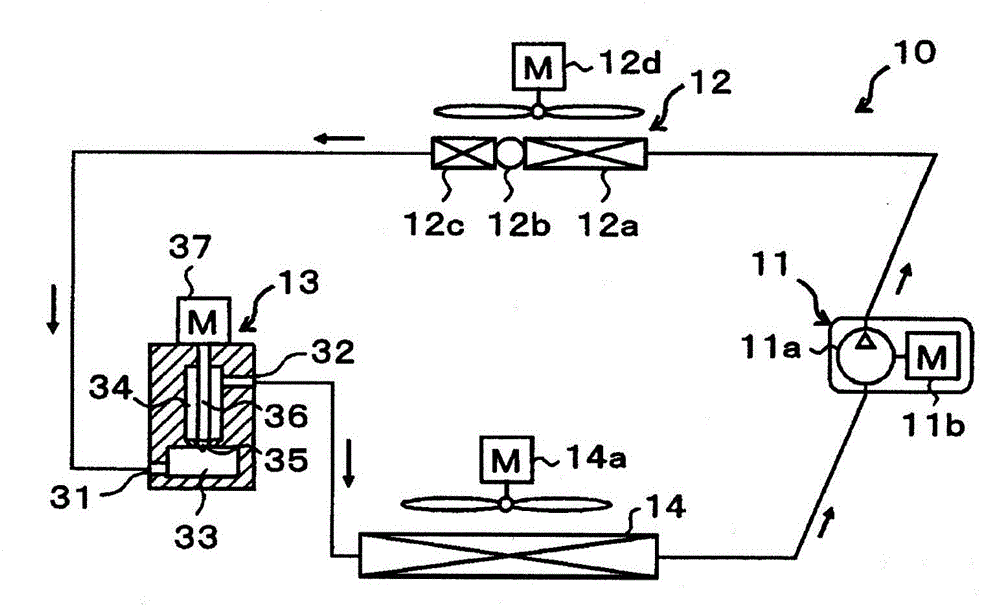

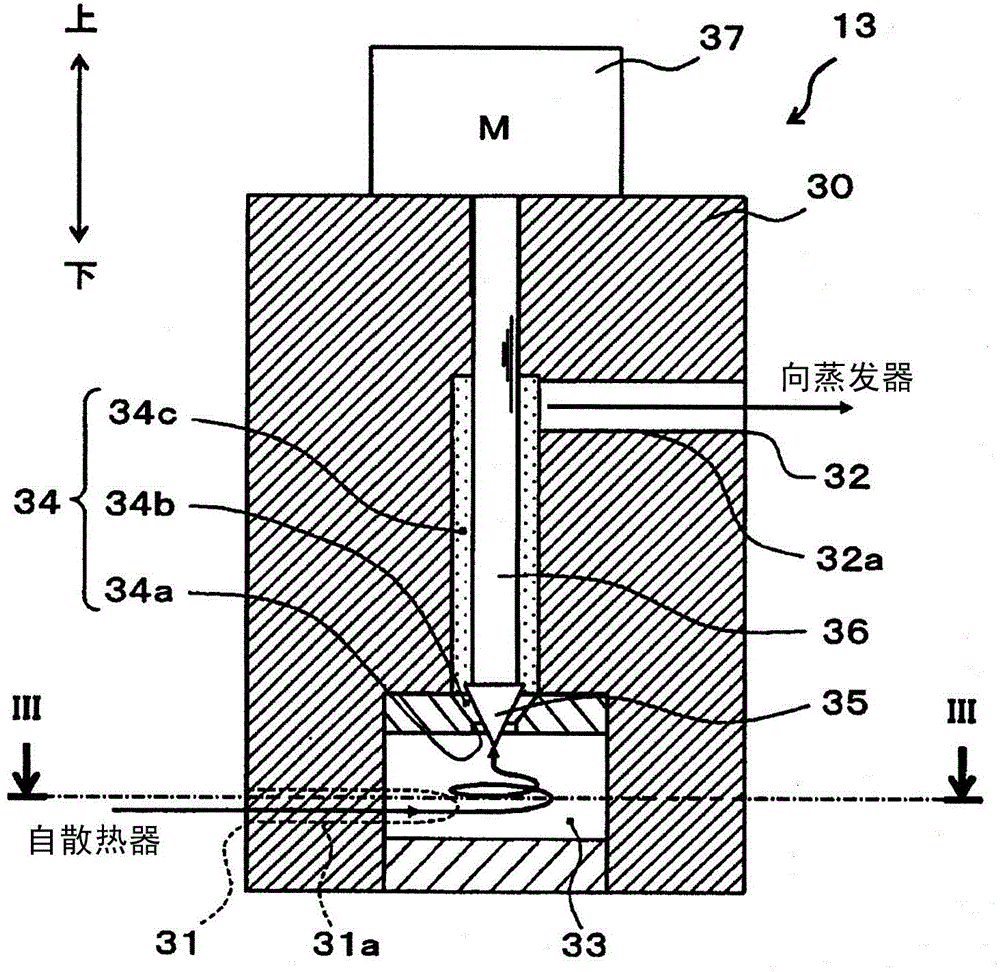

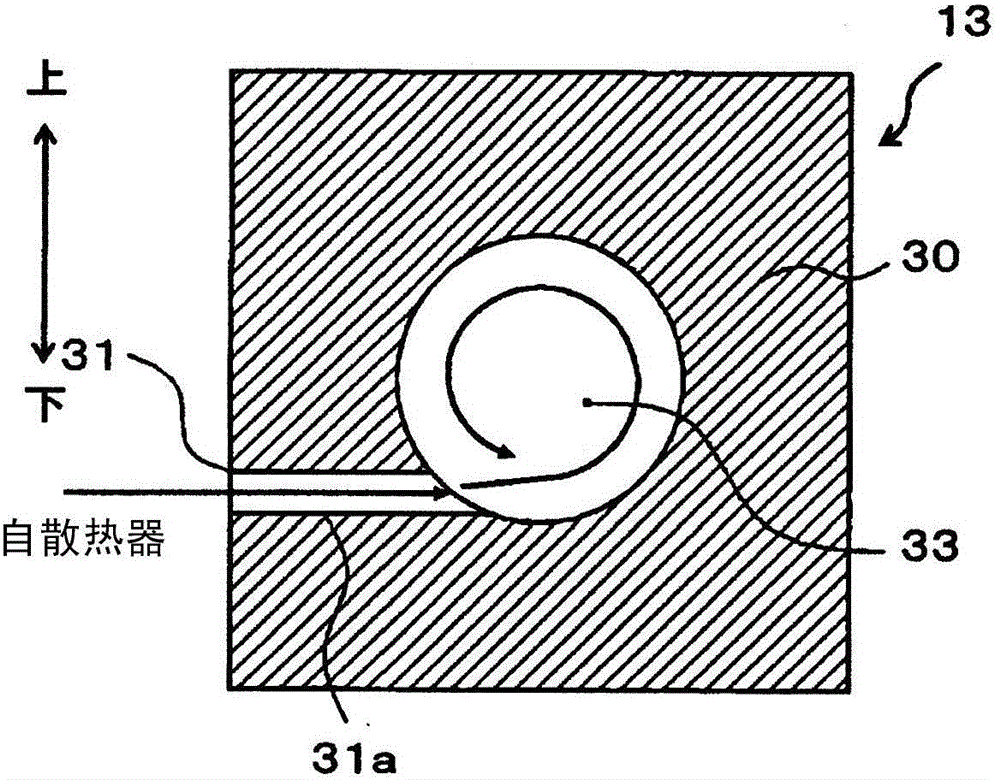

[0033] use Figure 1~3 , the first embodiment of the present invention will be described. Such as figure 1 As shown, the decompression device 13 of this embodiment is applied to the vapor compression refrigeration cycle system 10 . Further, this refrigeration cycle system 10 is applied to a vehicle air-conditioning apparatus, and functions to cool blown air blown into a vehicle interior as a space to be air-conditioned.

[0034] First, in the refrigeration cycle system 10, the compressor 11 is a device that sucks in a refrigerant, pressurizes it to become a high-pressure refrigerant, and discharges it. Specifically, the compressor 11 of the present embodiment is an electric compressor configured by accommodating a fixed-capacity compression mechanism 11 a and an electric motor 11 b that drives the compression mechanism 11 a in a single casing.

[0035] Various compression mechanisms, such as a scroll type compression mechanism and a vane type compression mechanism, can be e...

no. 2 approach

[0074] In the first embodiment, an example in which the valve element 35 formed in a conical shape is used as the valve element of the decompression device 13 was described, but in this embodiment, as Figure 4 As shown, a spool 35a formed in a spherical shape is employed. It should be noted that, in Figure 4 In , the same symbols are attached to the same or equivalent parts as those in the first embodiment. This also applies to the following drawings.

[0075] In addition, a cylindrical space (straight line portion) is formed on the passage forming member 30c disposed on the outer peripheral side of the valve body 35a to form the most upstream part of the refrigerant passage space 34, and the refrigerant flows continuously from the cylindrical space. A truncated conical space (taper) that expands in diameter. And, in this embodiment, if Figure 4 As shown, the minimum passage area portion 34a is formed at the connection portion between the straight portion and the tapere...

no. 3 approach

[0079] In the first embodiment, the decompression device 13 that electrically displaces the actuating rod 36 and the valve body 35 by the electric actuator 37 was described, but in this embodiment, An example of mechanically displacing the operating rod 36 and the valve body 35c. More specifically, as Figure 6 As shown in the cross-sectional view of , the decompression device 13 of this embodiment is configured as a so-called internal pressure equalizing type temperature type expansion valve.

[0080] First, in the main body part 30 of this embodiment, in addition to the aforementioned refrigerant inlet 31, refrigerant outlet 32, etc., a second refrigerant inlet passage 31b through which the low-pressure refrigerant flowing out of the evaporator 14 flows is formed. , and the second refrigerant outflow passage 32 b through which the evaporator 14 outflow refrigerant flowing in from the second refrigerant inflow passage 31 b flows out to the suction side of the compressor 11 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com