Oil well mouth sampling device, decompression device and sampling method

A technology of decompression device and sampling device, which is applied in wellbore/well components, earth-moving drilling, etc., can solve the problems of loss of authenticity, accuracy, health, safety, hidden dangers of environmental protection, liquid or gas splashing of samples, etc. To achieve the effect of reducing temperature, sampling safety, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

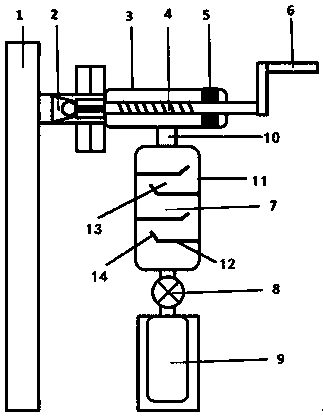

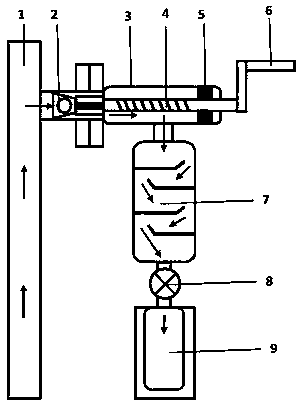

[0022] The detailed description and technical content of the present invention are described below with the drawings, but the drawings are only for reference and description, and are not used to limit the present invention.

[0023] as attached figure 1 , figure 2 As shown, a wellhead sampling device for an oil well comprises a decompression device 7 and a sampling bottle 9, the outlet of the decompression device is connected to the inlet of the sampling bottle, and also includes a check valve 2 and a check valve opening and closing device. The valve opening and closing device includes an outer pipe 3, a screw rod 4, a nut 5, and a ejector rod. The screw rod is located inside the outer pipe, and the front end of the screw rod is provided with a ejector rod. Process pipeline 1, the screw rod 4 is connected with the nut 5, the nut is blocked at the rear end of the outer tube 3, the front end of the outer tube is connected to the valve body of the check valve, the outer tube is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com