Interlocking fire extinguishing apparatus and sealing method thereof

An interlocking and sealing cover technology, which is applied in the field of fire extinguishing devices that rely on blasting materials to open or destroy containers, can solve the problems of fire extinguishing agent and detonator leakage, safety factor reduction, and removal of fire extinguishing agent, etc., to improve fire extinguishing efficiency and sealing performance Good, guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

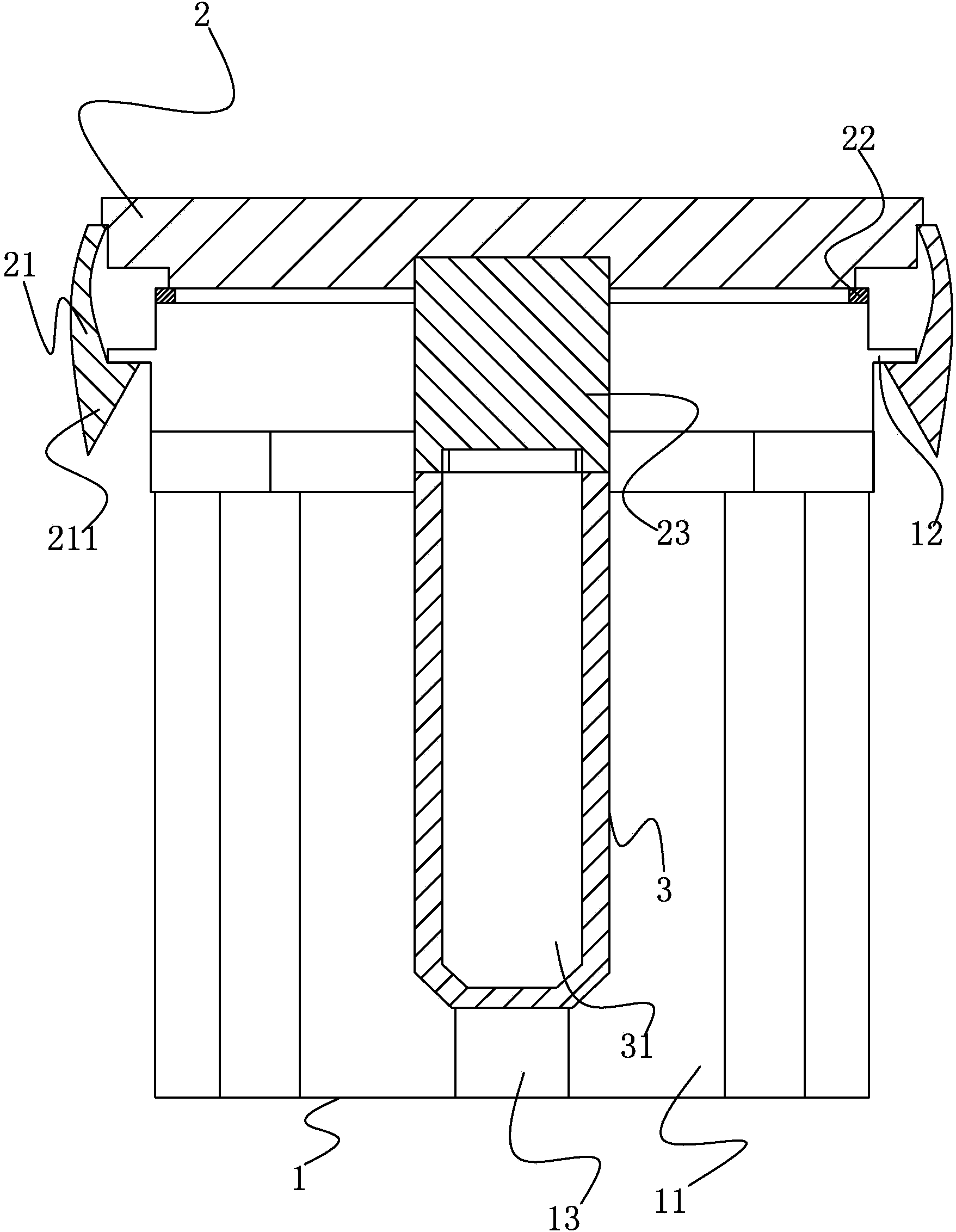

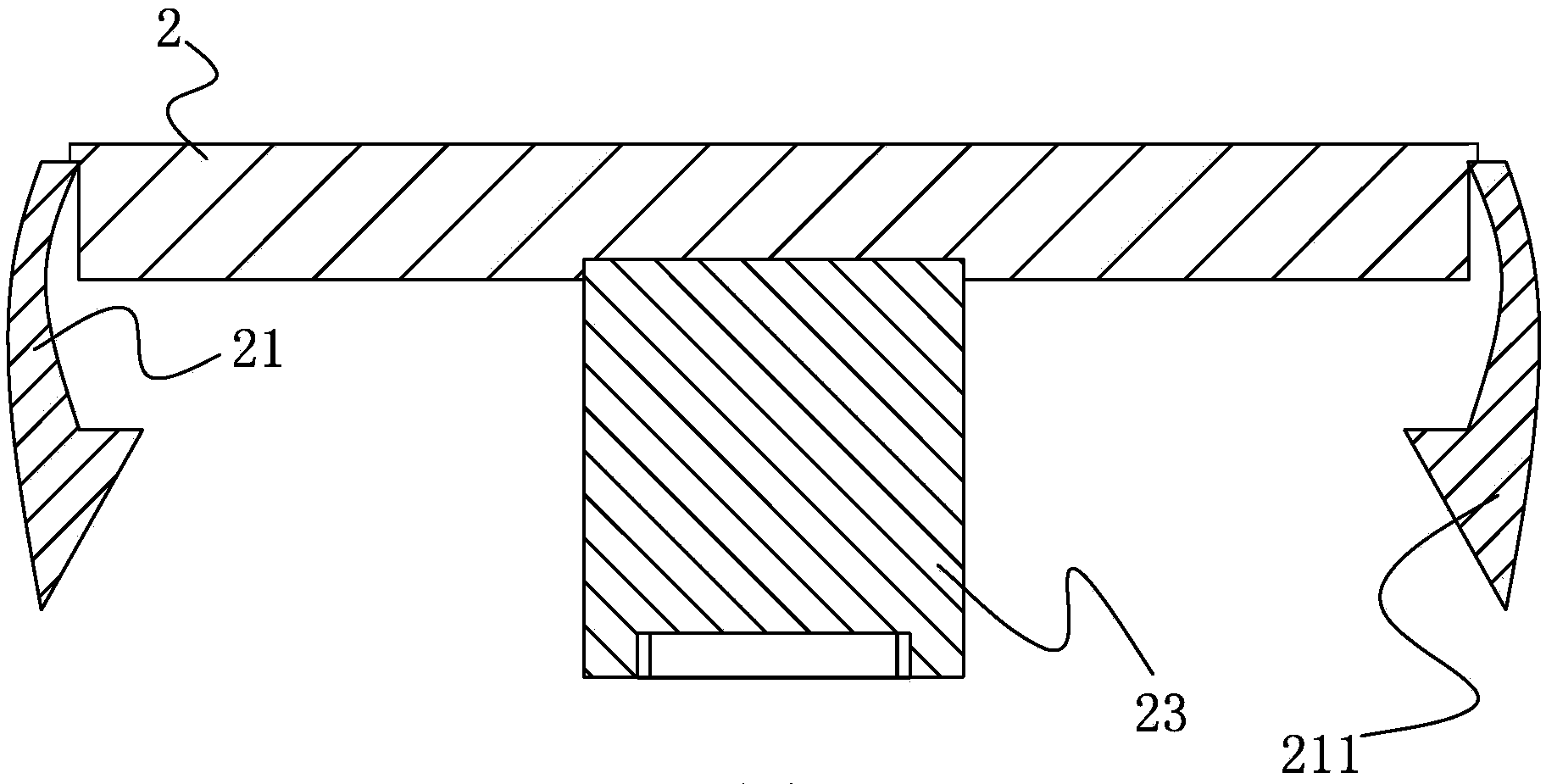

[0032] Such as figure 1 As shown, the buckle interlocking automatic fire extinguishing device of the present invention includes a container 1 and a fire extinguishing agent 11. It also includes a sealing boss 12, a sealing cover 2, a sealing claw 21, and a sealing cover protrusion 23.

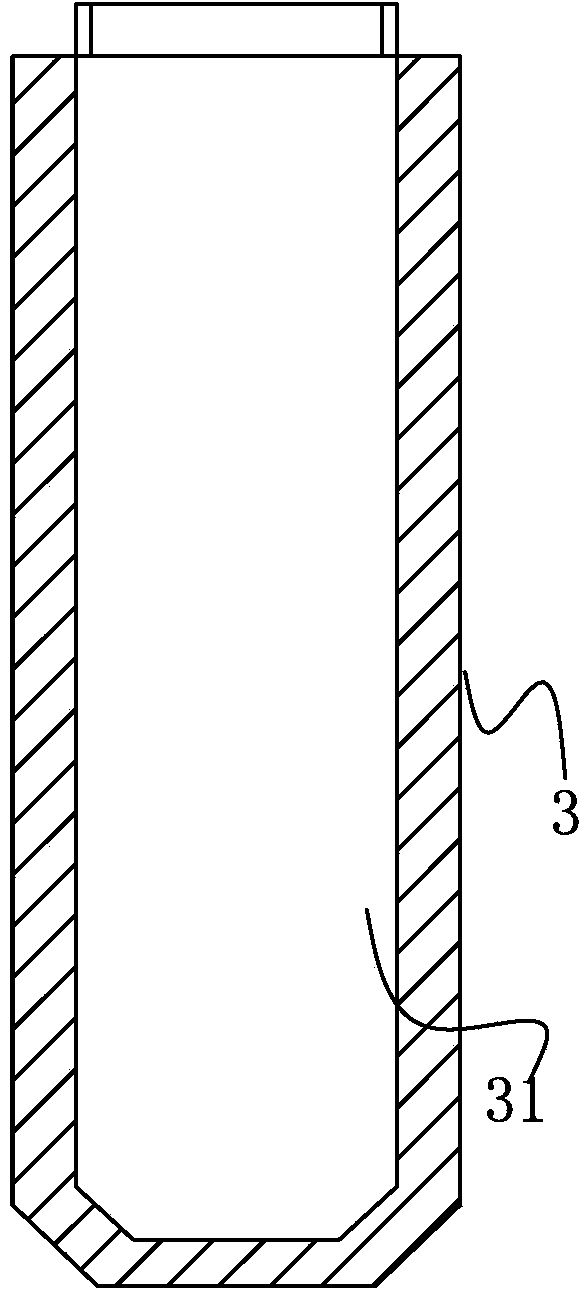

[0033] Such as Figure 4 with Figure 5 As shown, the container 1 opens upward. The container 1 is a cylinder. The thickness of the circumferential wall of the container 1 is h=1.3mm. An arc-shaped groove 13 is vertically arranged on the circumferential surface of the container 1, and the number of the arc-shaped grooves 13 is more than four, preferably eight. The arc groove 13 has a length a=16mm and a width b=2.5mm. The shortest distance between the arc-shaped groove 13 and the inner wall of the container 1 is h=1.1mm. The width of the arc groove 13 is the same as the interval between the arc grooves 13. The container 1 contains a fire extinguishing agent 11. The upper annular sealing bos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com