Low-temperature boiling chlorination furnace, slag discharging and flow guiding device thereof, and low-temperature boiling chlorination method

A technology of fluidized chlorination furnace and diversion device, which is applied in chemical instruments and methods, titanium halides, chemical/physical processes, etc. It can solve problems such as shutdown and dead furnace, difficult temperature control, and incomplete reaction of materials, etc., and achieve reduction Discharge amount, effect of increasing chlorination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, the low-temperature boiling chlorination furnace, its slag discharge diversion device and the low-temperature boiling chlorination method of the present invention will be described in detail in combination with exemplary embodiments.

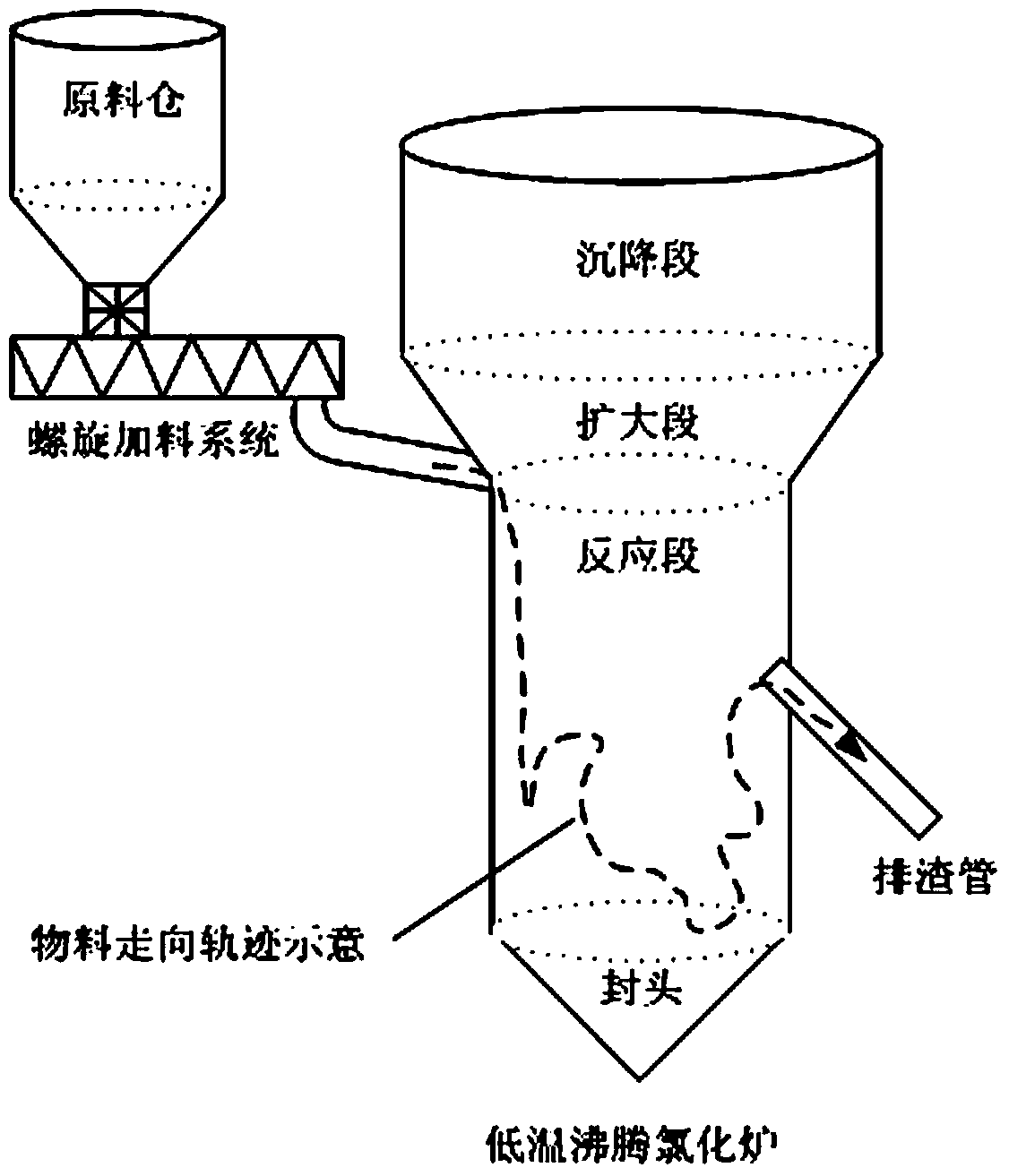

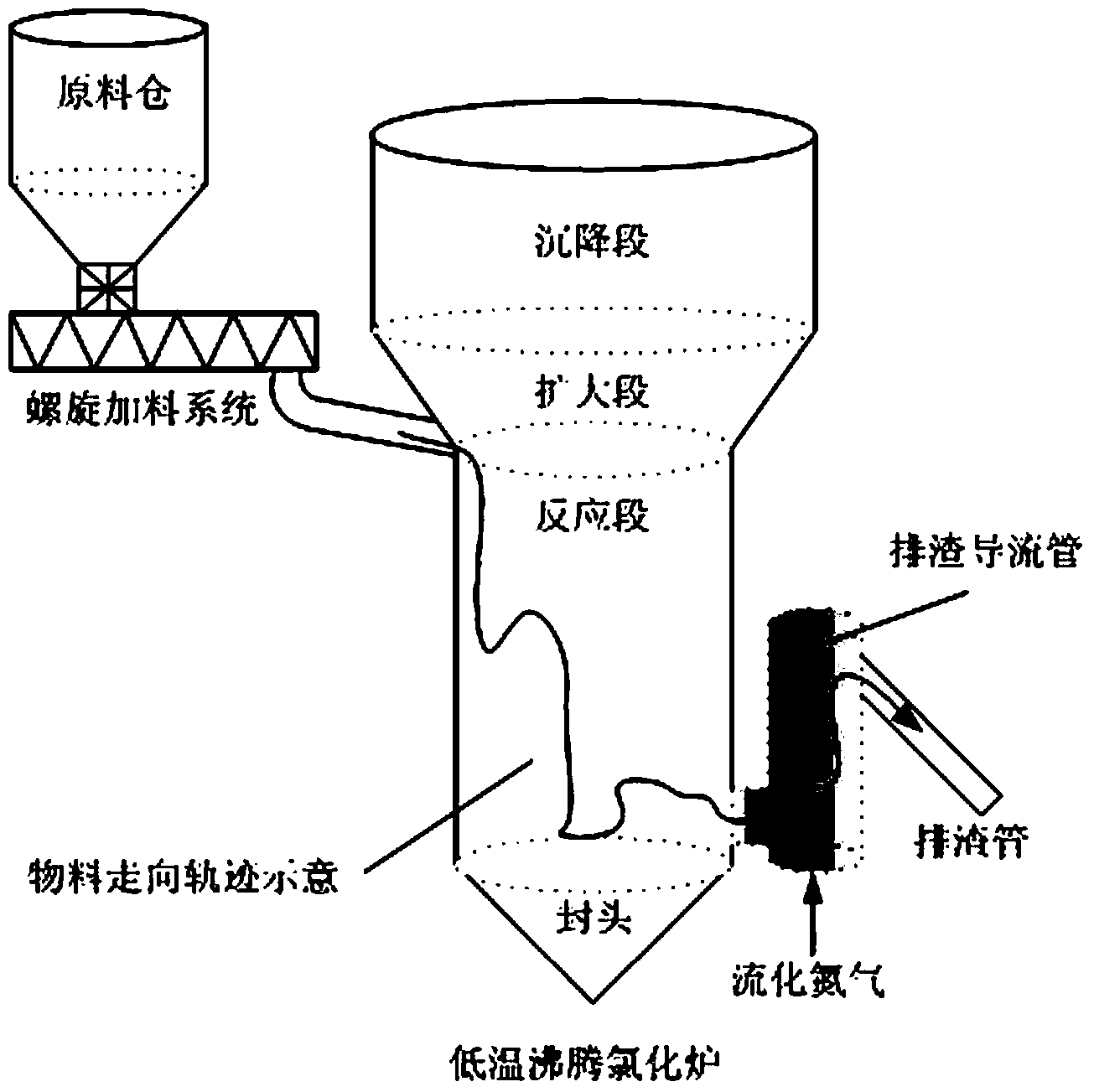

[0016] The inventor finds through trial and error and analysis that: in adopting figure 1 When discharging the waste slag with the structure shown, when a large amount of slag is discharged to take away a large amount of heat of reaction to reduce the temperature in the furnace to ensure that the temperature in the furnace is in an appropriate range, a large amount of incompletely reacted materials will be directly discharged for chlorination furnace, resulting in waste of resources and low chlorination rate, and unreacted excess chlorine will enter the tail gas treatment system; in addition, when the slagging speed is too fast, it will also cause the temperature of the chlorination furnace to drop rapidly, resulting in death ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com