Passive dynamic vibration-absorbing track plate

A technology of dynamic vibration absorption and track plate, applied in the direction of track, road, ballast layer, etc., can solve the problems of reducing the rigidity of the track structure, increasing the displacement of the track structure, limited vibration reduction effect, etc., so as to eliminate harmful vibration and reduce vibration. Composition, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings.

[0018] When the train passes, a strong downward force will be generated on the track slab body 10, and the track slab body 10 will then transmit this force to the offline foundation. In the existing track structure, a spring, rubber and other damping components are arranged between the track plate main body 10 and the under-line foundation to play a certain buffering effect. However, due to the limitation of the natural frequency of the track structure, not only the vibration of the frequency band cannot be affected. The components play a buffer role, but will amplify the vibration components near the natural frequency of the track structure.

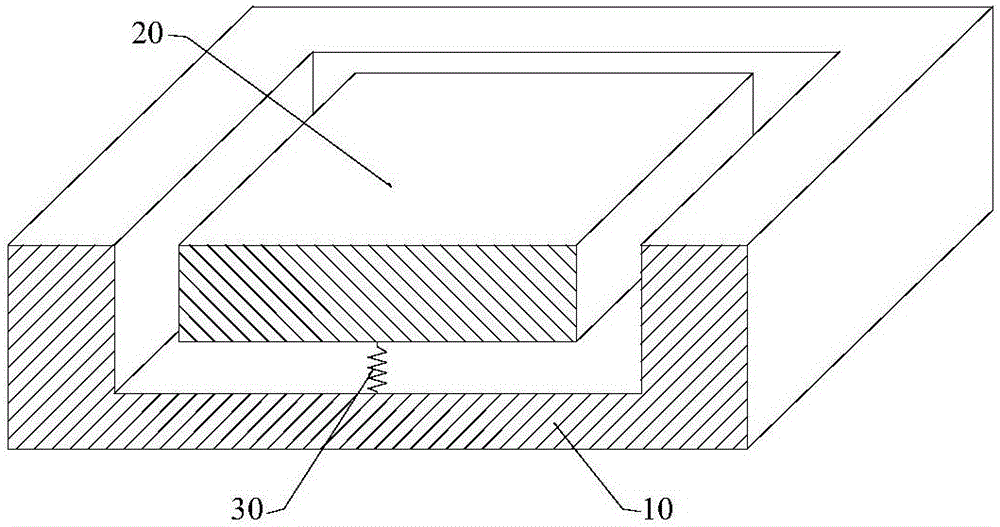

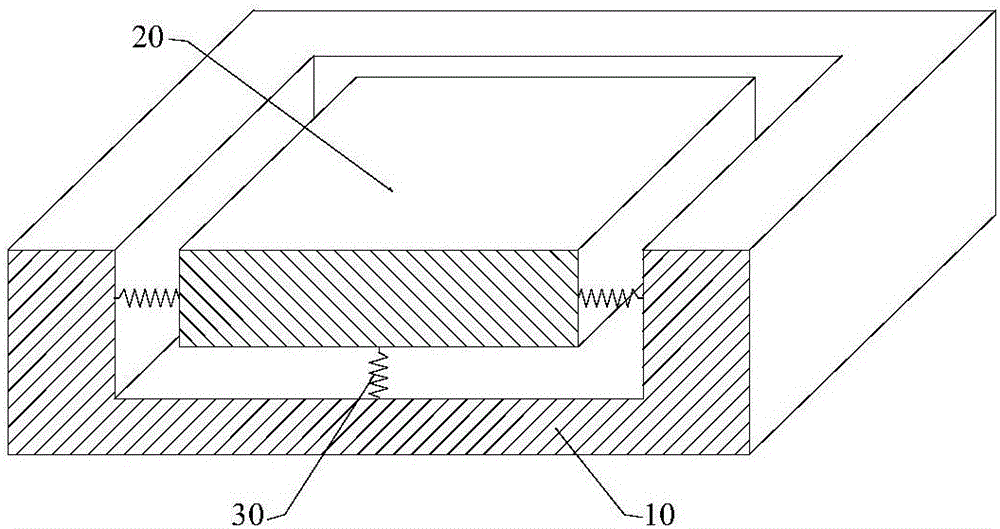

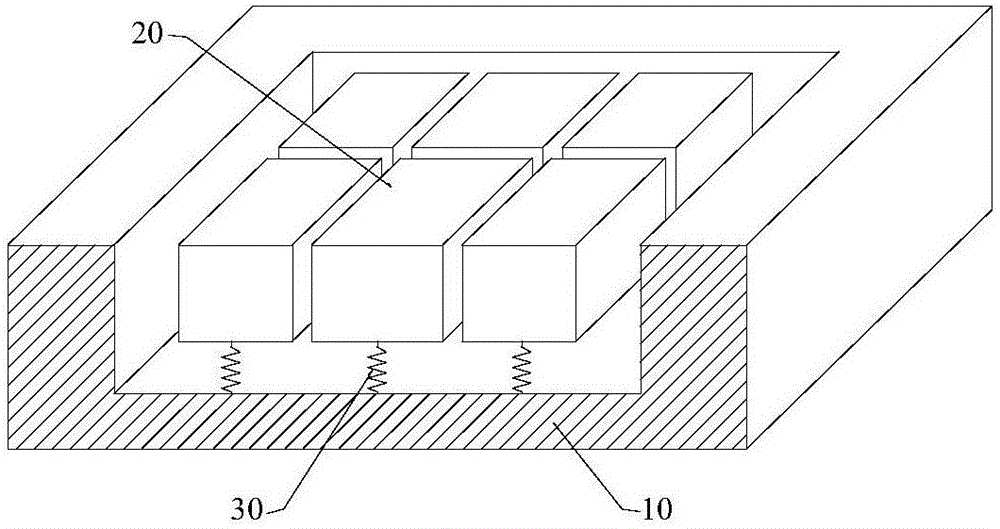

[0019] Reference Figure 1 to Figure 6 , The passive dynamic vibration-absorbing track plate of the present invention includes a track plate main body 10 on which an additional mass 20 is provided in the non-contact space area with the rail, bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com