River model plastic grass roughening method

A technology of river engineering model and plastic grass is applied in the field of roughening of river engineering physical model test, which can solve the problems of labor and material cost, and achieve the effect of simple and practical roughening method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

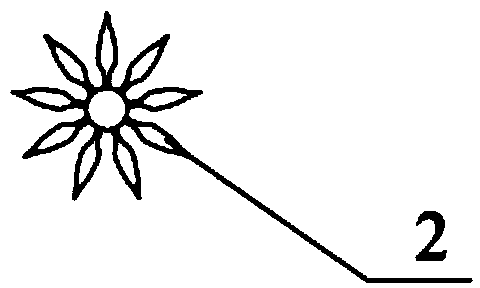

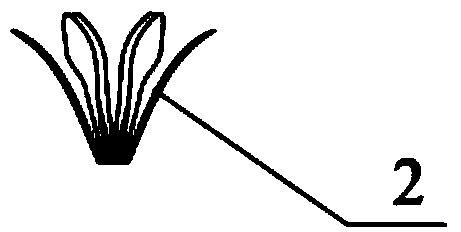

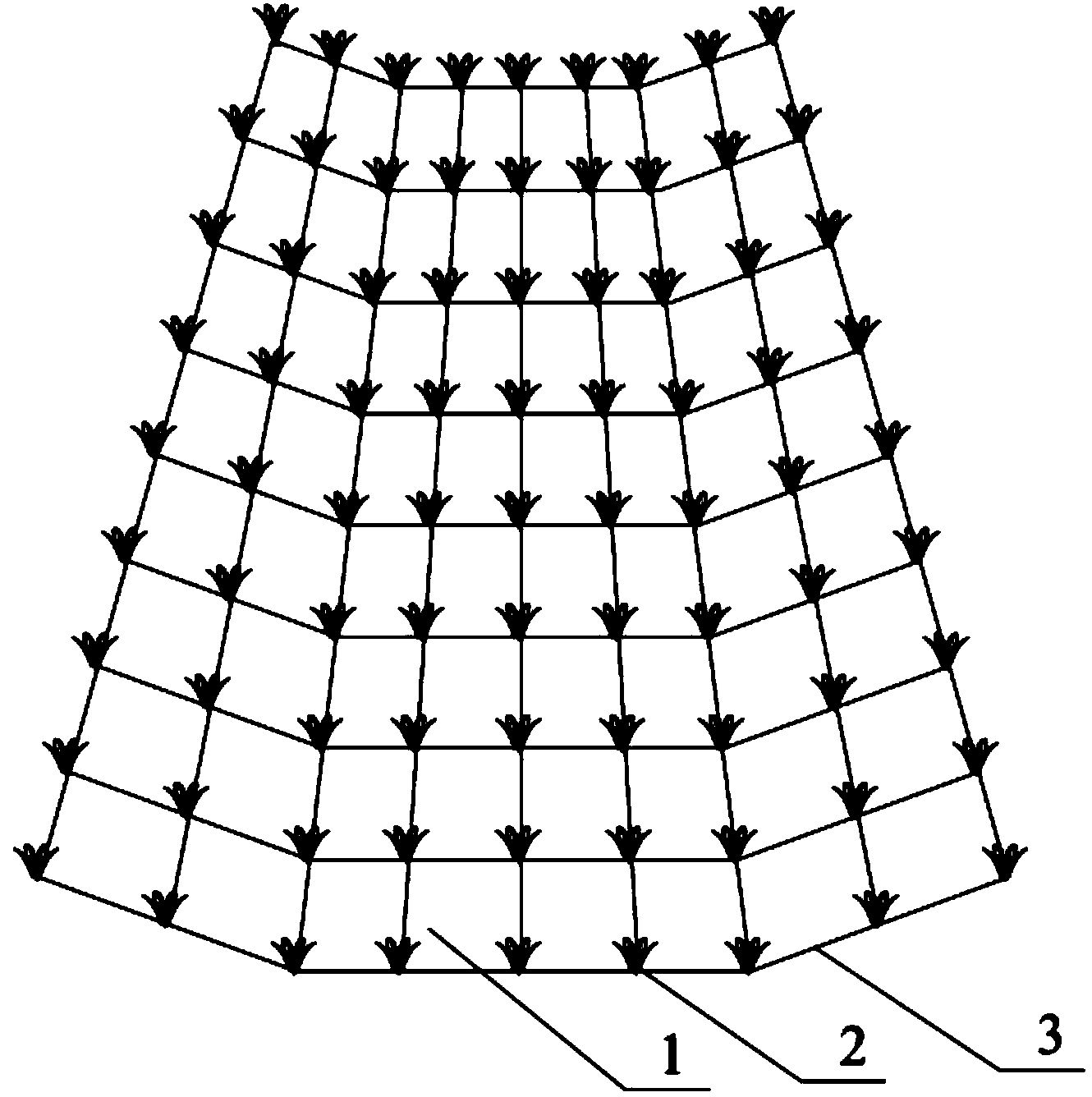

[0022] The river engineering model needs to know the roughness and flow conditions of the natural river. According to these conditions, the roughness n and the water depth H required by the model are calculated based on the roughness scale and vertical scale of the model. Assuming that the calculated model is rough Ratio n=0.022, model water depth H=about 0.10m, model roughness n and model water depth H are brought into the calculation formula proposed by the present invention: Calculate the required plastic grass spacing L=0.15m, the plastic grass adopts figure 1 The plastic grass shown (height 2.5cm, 9 petals, each petal length 4.2cm, widest 0.7cm, base diameter 1.2cm), according to Figure 5 Make a square grid as shown (side length L=0.15m), use a small amount of cement to glue the plastic grass on the model surface at the grid point ( Image 6 ).

Embodiment 2

[0024] According to the roughness and flow conditions of the natural river, the roughness n required by the model and the water depth H of the model are calculated from the roughness scale and vertical scale of the model. Assume that the calculated model roughness n=0.020, and the model water depth H =0.20m or so, the model roughness n and the model water depth H are brought into the calculation formula proposed by the present invention: Calculate the required plastic grass spacing L=0.16m, the plastic grass adopts figure 1 The plastic grass shown (height 2.5cm, 9 petals, each petal length 4.2cm, widest 0.7cm, base diameter 1.2cm), according to Figure 5 As shown, the square grid (side length L=0.16m) is produced, and a small amount of cement is used to glue the plastic grass to the model surface at the grid point to meet the roughening requirements of the model.

Embodiment 3

[0026] After understanding the roughness and flow conditions of the natural river, calculate the roughness n required by the model and the water depth H of the model based on the roughness scale and vertical scale of the model. Assume that the calculated model roughness n=0.028, and the model water depth About H=0.15m, model roughness n and model water depth H are brought into the calculation formula proposed by the present invention: Calculate the required plastic grass spacing L=0.09m, the plastic grass adopts figure 1 The plastic grass shown (height 2.5cm, 9 petals, each petal length 4.2cm, widest 0.7cm, base diameter 1.2cm), according to Figure 5 As shown, a square grid (side length L=0.09m) is produced, and the plastic grass is glued to the grid points of the model surface with a small amount of cement.

[0027] According to Examples 1-3, it can be concluded that the method of the present invention can predetermine the roughening distance of the plastic grass, avoiding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com