Non-excavation construction method of ultra-large-diameter poly ethylene (PE) drain pipe

A technology with super large diameter and construction method, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve problems such as weak butt joints of pipe bodies, poor sealing of pipe bodies, and difficulty in pipe traction, etc., to achieve The butt joint of the pipe body is firm, the sealing performance of the pipe body is strong, and the effect of traction is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

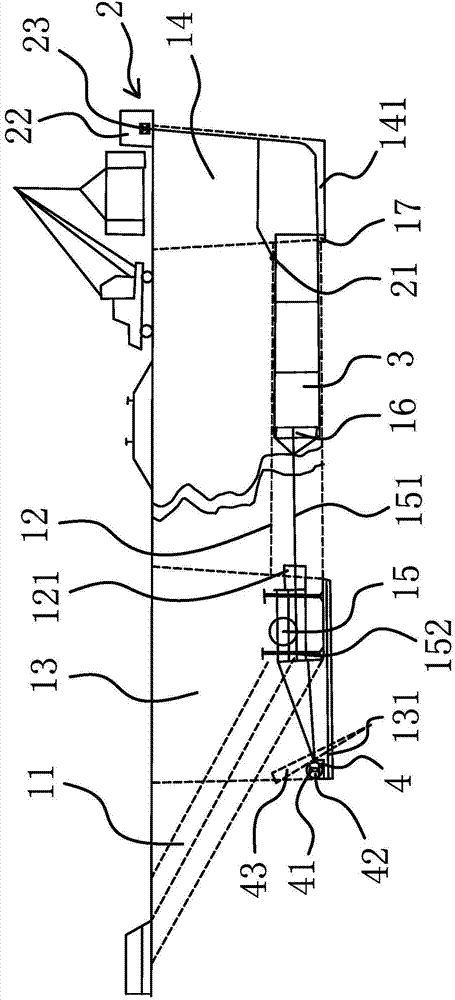

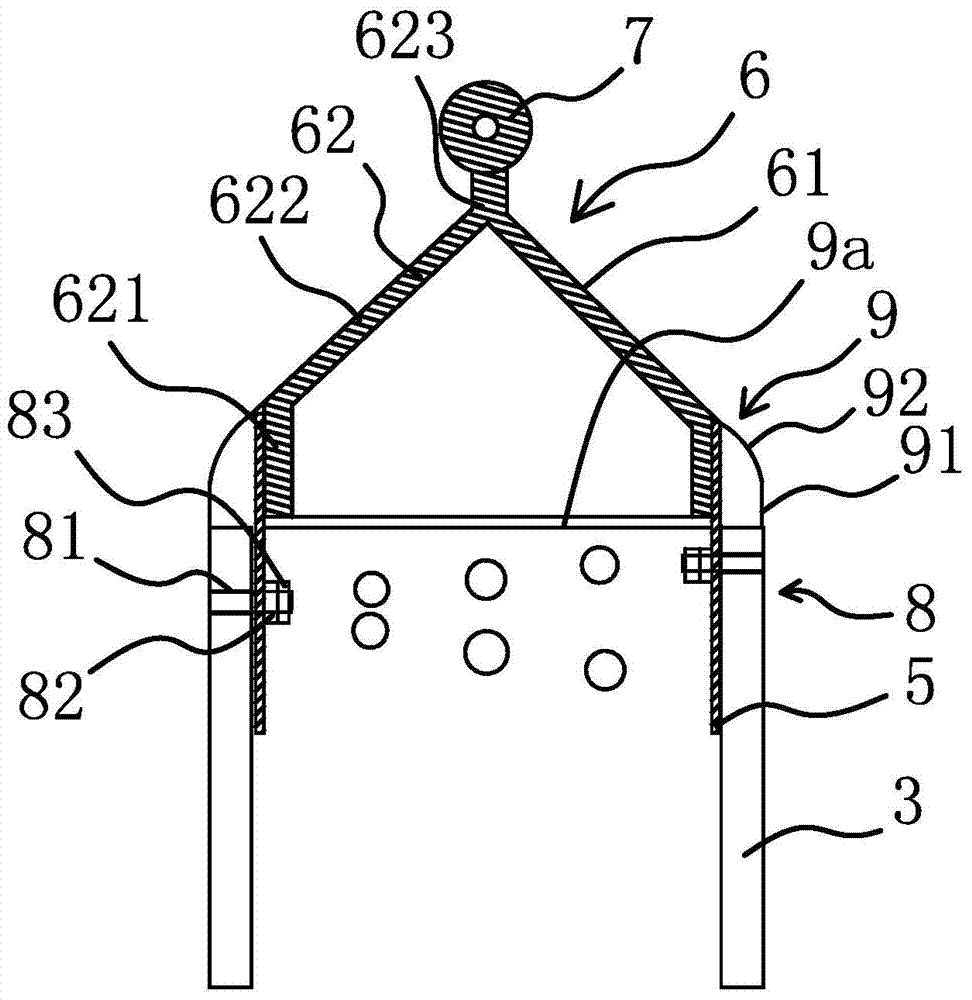

[0033] Such as Figure 1-2 As shown, the non-excavation construction method of the super-large-diameter PE drainage pipe includes: A, drilling: according to the geological conditions of the designed pipeline and the previous drilling, the inclined hole 11 is first drilled downwards, and then drilled horizontally Get out the straight hole 12 communicating with the lower end of the inclined hole 11, dig out the first construction pit 13 that is vertically arranged and communicated with the inclined hole 11 and the straight hole 12 at the junction of the inclined hole 11 and the straight hole 12, and in the straight hole 12 The other end digs out the second construction pit 14 that is vertically arranged and communicated with the straight hole 12; B, equipment installation: install the hoist 15 in the first construction pit 13, connect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com