Intelligent drying oven capable of monitoring weight in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail below in conjunction with embodiment and accompanying drawing thereof, but the present invention is not limited by embodiment:

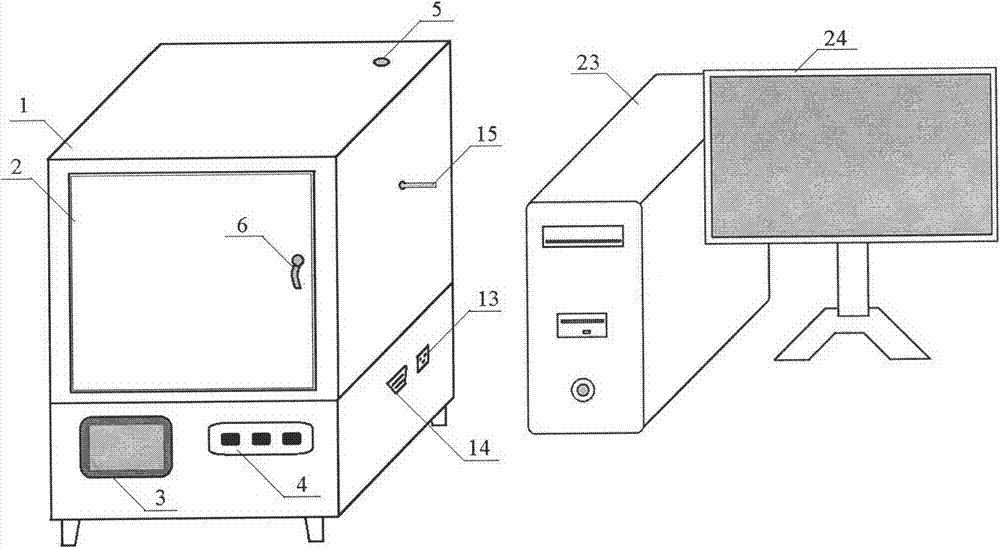

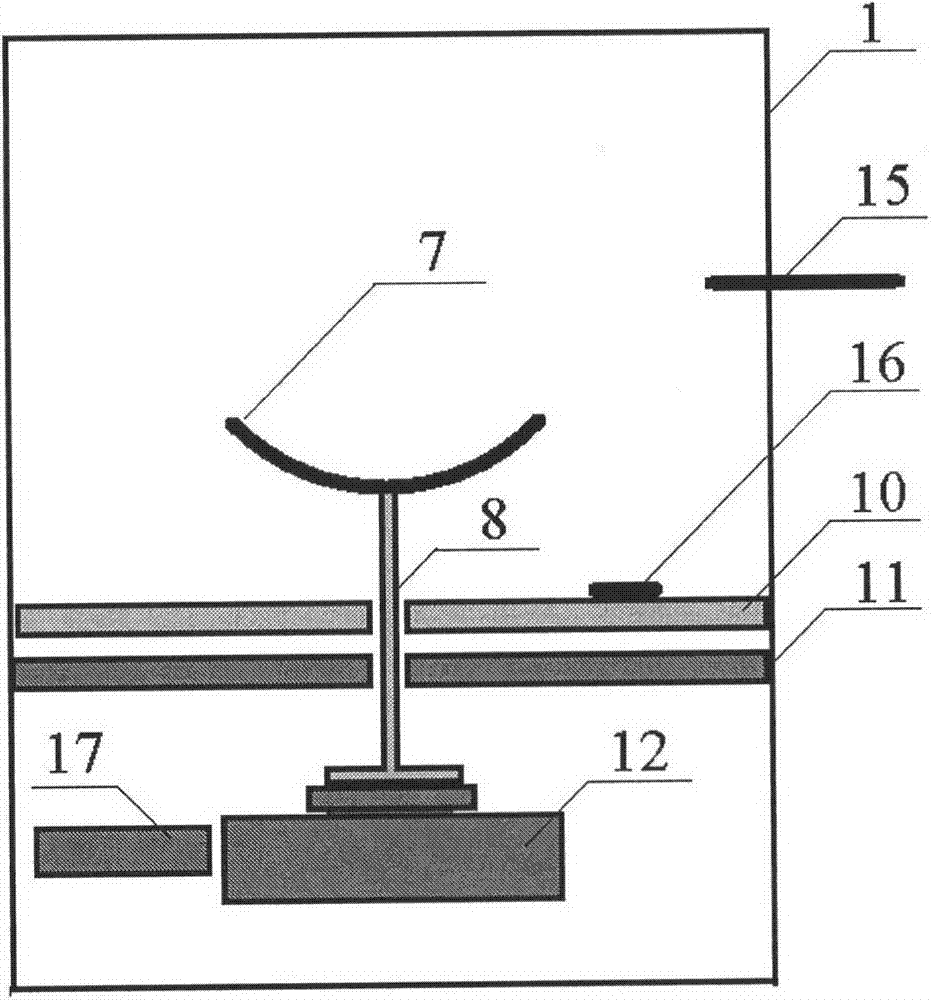

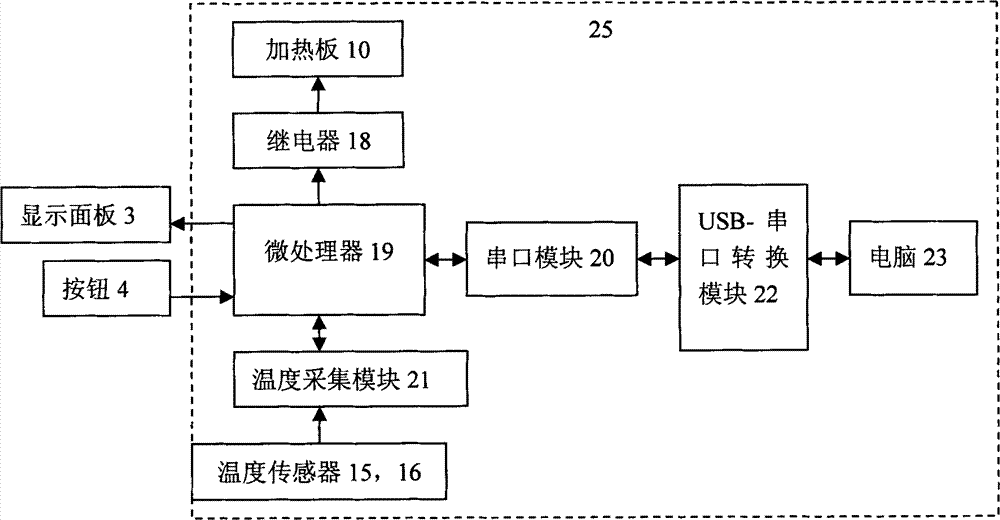

[0017] A kind of intelligent oven that weight can be monitored in real time of the present invention (referring to Figure 1-4 ), the intelligent oven whose weight can be monitored in real time comprises an oven casing 1 and a temperature control system 24. The feature of the oven cabinet 1 is that the tray 7 in it is directly placed on the high-precision electronic balance 12 through the support rod 8, the oven cabinet 1 is divided into upper and lower parts, and the upper part is composed of a temperature sensor 15, 16 and a heating plate 10, and the tray 7 is in its central position, the temperature acquisition and measurement device 17 and the high-precision electronic balance 12 are placed in the lower part, and the upper and lower parts are isolated by the heat insulating material 11, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com